Laminated glass stacking device

A technology of laminated glass and stacker, which is applied to instruments, measuring devices, mechanical devices, etc., can solve the problems of low resolution, large parallax, and low reading accuracy, and achieve stable measurement value reading, convenient operation, and positioning. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below through specific embodiments in conjunction with the accompanying drawings.

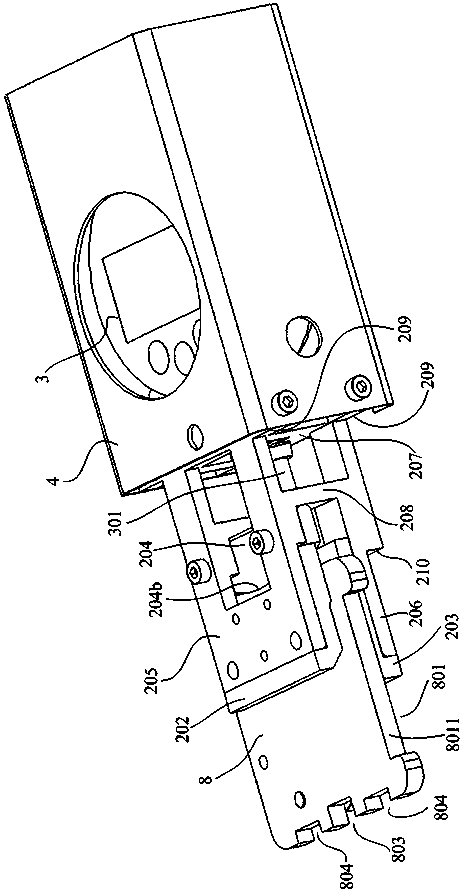

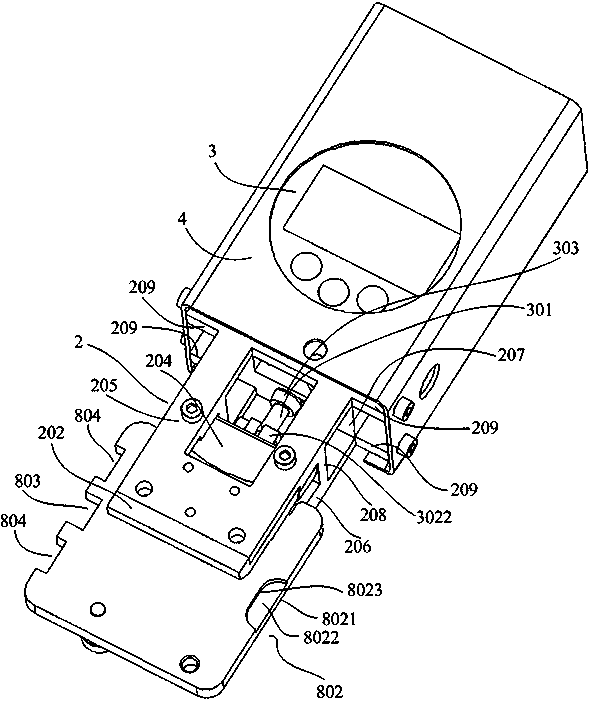

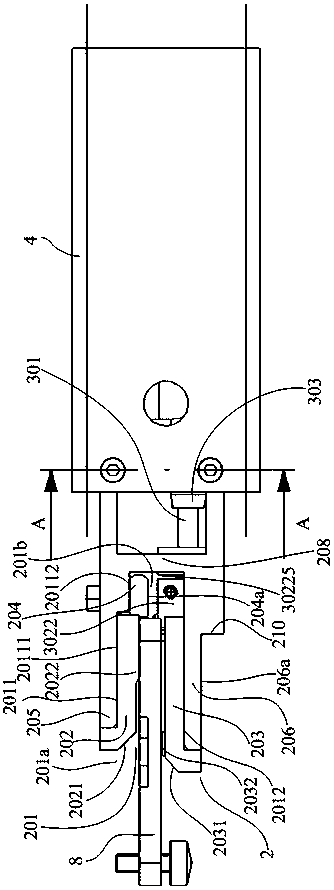

[0035] Please refer to Figure 1 to Figure 18, the embodiment of the present invention laminated glass multimeter, laminated glass 1 includes two pieces of glass stacked up and down and interlayer 102 arranged between the two pieces of glass, the multimeter is used to measure the difference in shape and size of the two pieces of glass . The multimeter includes a clamping seat 2 , a dial gauge 3 arranged on the clamping seat 2 and a protective cover 4 for protecting the dial gauge 3 . One side of the clamping seat 2 is provided with an insertion groove 201 suitable for inserting the laminated glass 1. The insertion groove 201 has an opposite insertion end 201a and a limit end 201b. The opening end of the insertion groove is the insertion end 201a of the insertion groove. , the end opposite to the opening end of the insertion slot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com