Pulsator structure and washing machine

A washing machine and pulsator technology, applied in the field of washing machines, can solve the problems of clothes deformation, seriousness, knotting, etc., achieve quick disassembly and installation, suitable for popularization and use, and expand functionality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

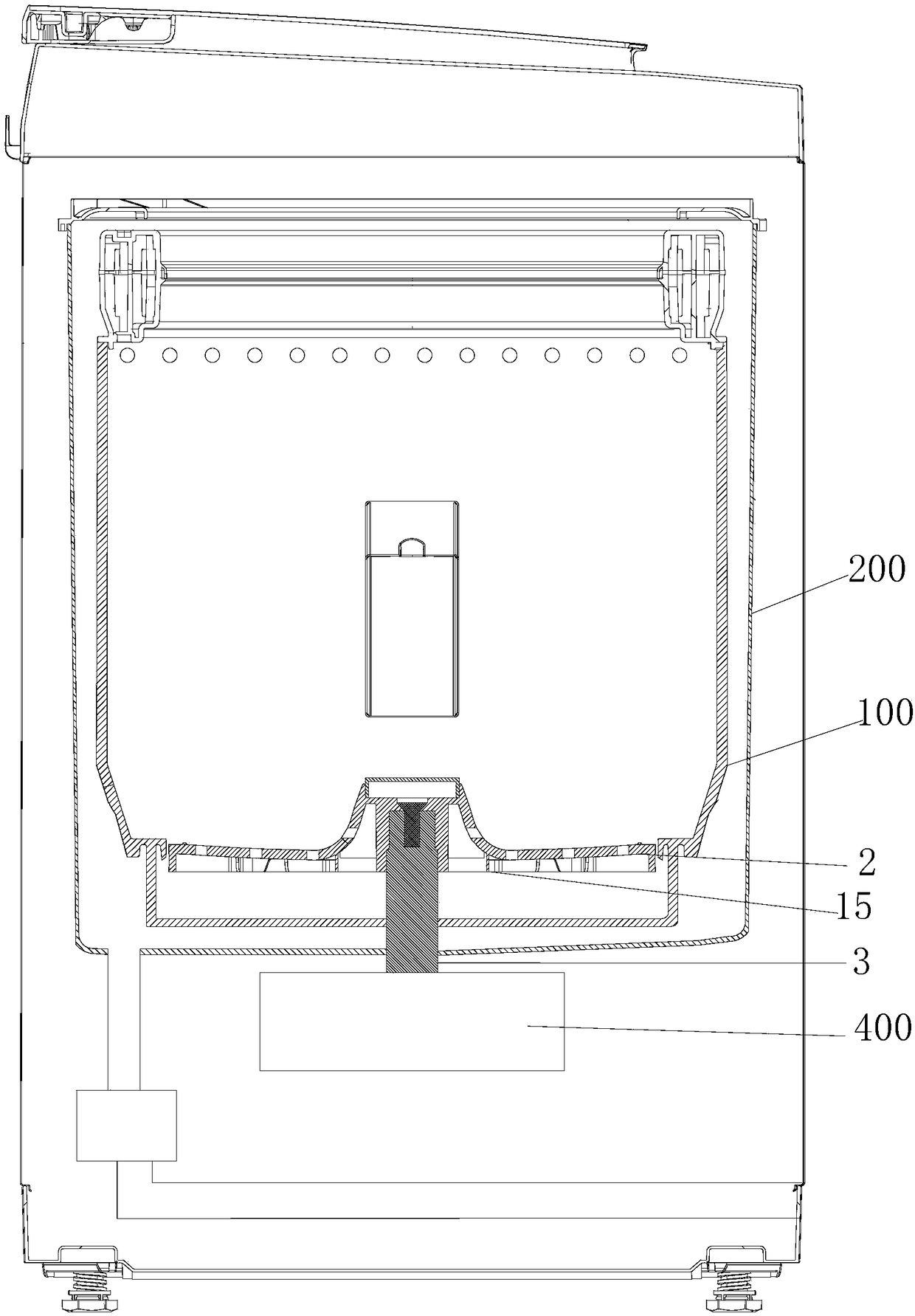

[0043] Such as Figure 2 to Figure 8 As shown, the embodiment of the present invention introduces a washing machine, which includes an outer tub 200 and an inner tub 100. A pulsator structure 300 is installed in the inner tub 100. A motor 400 is installed at the bottom of the outer tub 200. The motor shaft 3 of the motor 400 passes through the Through the bottom of the outer tub and the bottom of the inner tub, the penetrating end of the motor shaft 3 is meshed with the bottom center of the pulsator structure 300 to drive the pulsator structure 300 to rotate and stir the clothes and water in the inner tub 100 so that the two rub against each other to achieve The purpose of washing clothes.

[0044] In the embodiment of the present invention, the pulsator structure 300 includes a first pulsator 1 and a second pulsator 2 that are detachably connected up and down, the first pulsator 1 is installed above the second pulsator 2, and the The upper surface of the first pulsator 1 is pr...

Embodiment 2

[0048] Such as Figure 5 As shown, in this embodiment, the pulsator structure 300 includes a first pulsator 1 and a second pulsator 2 that are detachably connected up and down.

[0049] Such as Figure 4 As shown, in this embodiment, the lower surface of the first pulsator 1 and the upper surface of the second pulsator 2 are arranged so as to minimize the gap between the two, thereby reducing the overall structure of the pulsator structure 300. height, reducing the volume occupied by the pulsator in the inner barrel 100.

[0050] Such as Figure 6 As shown, in this embodiment, the first pulsator 1 and the second pulsator 2 are respectively provided with a plurality of water permeable holes 10 arranged vertically through. The permeable holes 10 on the second pulsator 2 are evenly arranged on a plurality of helical curves, and each helical curve is symmetrically arranged with respect to the center of the second pulsator. The spiral curve is a curve gradually away from any ra...

Embodiment 3

[0056] Such as Figure 5 and Figure 8 As shown, in this embodiment, the pulsator structure 300 includes a first pulsator 1 and a second pulsator 2 that are detachably connected up and down. The first pulsator 1 and the second pulsator 2 are fixedly connected through a quick release structure. By detaching the first pulsator and the second pulsator for detachable fixed installation, the user can easily and quickly disassemble and install the first pulsator, so that the user can wash the clothes according to the actual working conditions of the clothes. In other cases, the laundry is washed using the first pulsator and / or the second pulsator.

[0057] Such as Figure 4 As shown, in this embodiment, the center of the second pulsator 2 is provided with an upwardly protruding mounting protrusion 11, and the center of the first pulsator 1 is provided with a first washing rib 8, and the first washing rib The interior of 8 is hollow to form a mounting slot for inserting the mount...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com