Drilling bit for plastic plate drill hole

A plastic plate and drill bit technology, which is applied in the field of drilling bits and processing machinery, can solve the problems of not being too fast, uneven force, too much force, etc., and achieve simple structure, high processing efficiency, and quick installation and disassembly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with accompanying drawings and embodiments.

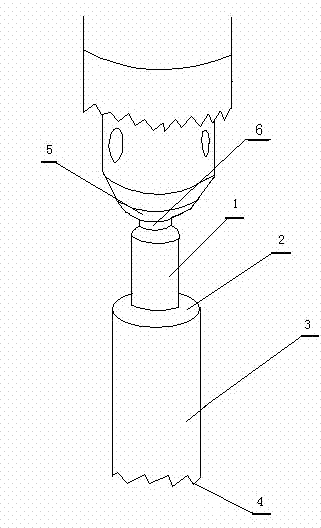

[0010] See attached figure 1 , the present invention proposes a plastic plate drilling bit, comprising a straight shank 1, the top of the straight shank 1 is provided with a chuck 6, the diameter of the chuck 6 is smaller than the diameter of the straight shank 1; the bottom of the straight shank 1 is fixed vertically Connect a cylinder 3, the cylinder 3 is coaxial with the straight handle 1, the straight handle 1 ensures the fixation of the cylinder 3, and it is not easy to be deformed during work to cause safety accidents; and the cylinder 3 is a hollow structure, and the upper end passes through the sealing The plate 2 is sealed, the lower end is an opening, and the bottom of the opening is a flat circumference, and the entire circumference is ground into a circular blade, and the blade is uniformly distributed with a circle of processing saw-shaped teet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com