Automatic electroplating machine capable of being used for irregular parts and facilitating clamping

An irregular electroplating machine technology, applied in plating tanks, electrolytic processes, electrolytic components, etc., can solve the problems of weak continuous electroplating ability, inaccurate electroplating time operation, and consumption of manpower and material resources. Maintaining stability and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037]In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. .

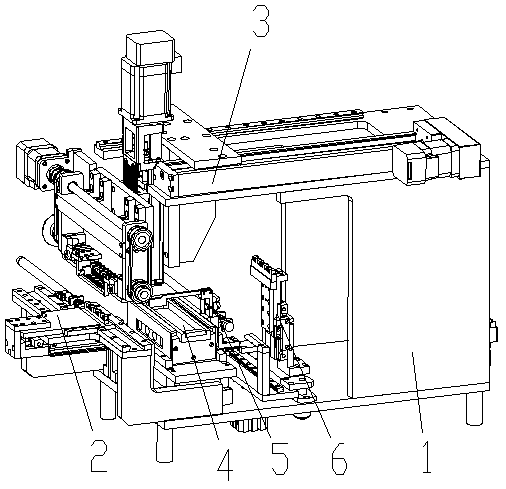

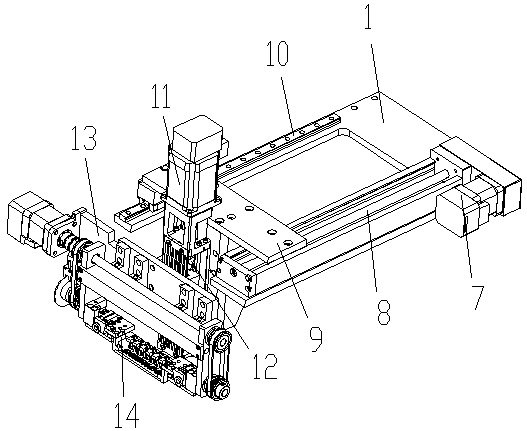

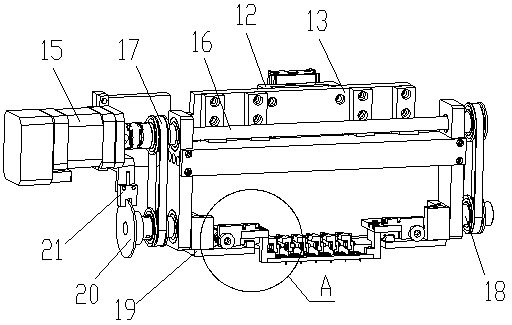

[0038] Such as Figure 1-Figure 6 As shown, the specific structure of the present invention is: a kind of automatic electroplating machine that can be used for the convenient clamping of irregular parts, it comprises frame 1, and the middle part of described frame 1 is provided with electroplating pool 4, and described electroplating pool The left side of 4 is provided with a feeding device 2 that cooperates with the carrier 33, and the carrier 33 is evenly provided with no less than two sets of socket columns that are socketed and matched with the product 26. The frame 1 The upper part is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com