Standard Barrier Film

A gas barrier film, a standard technology, applied in the direction of suspension and porous material analysis, measuring devices, scientific instruments, etc., can solve the problem of determining the time point when the water vapor transmission rate is saturated, destroying the inorganic gas barrier layer, and changing the measurement accuracy Bad question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

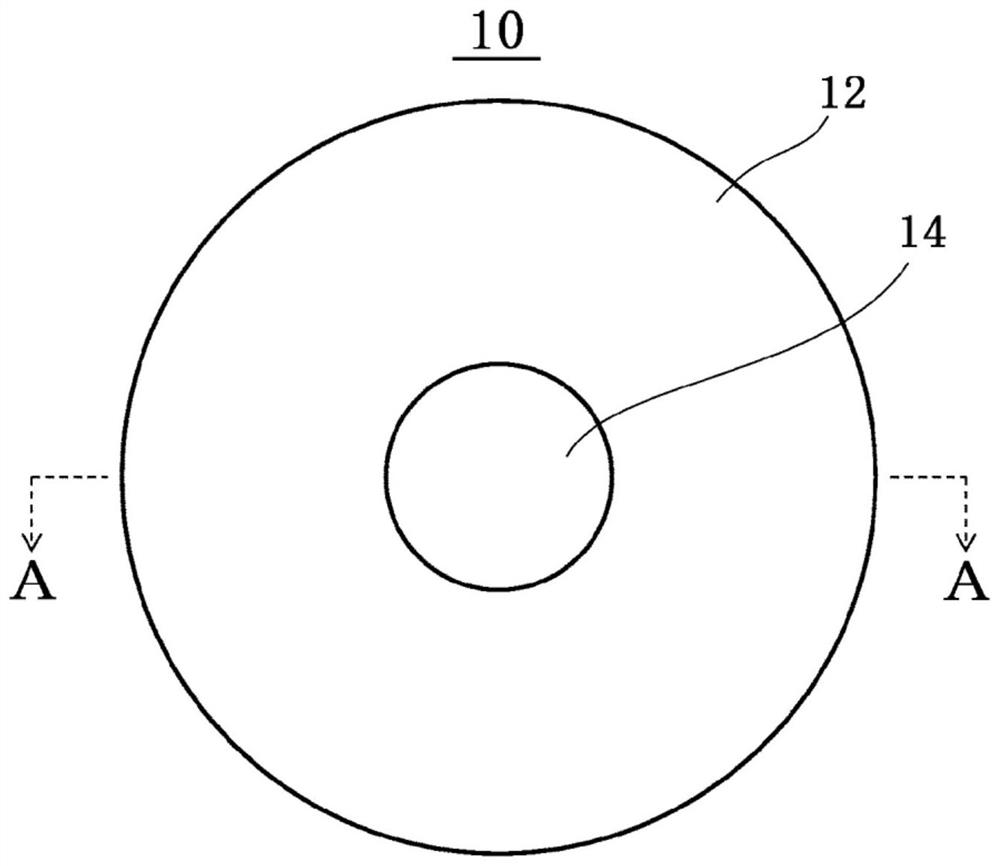

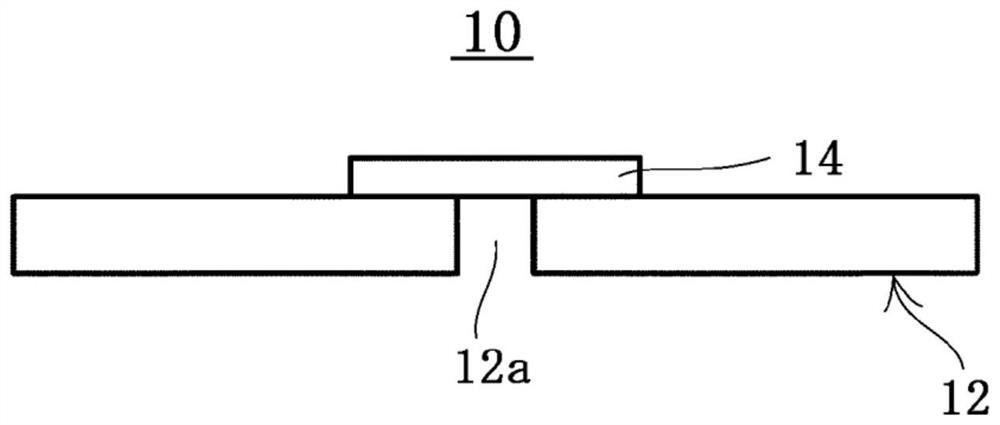

Embodiment 1

[0050] First, 50 g of a uniform gel obtained by mixing 20 parts by mass of Li-type montmorillonite and 80 parts by mass of water (hereinafter, sometimes referred to as "Li-type montmorillonite 20% gel"), N-methyl - After mixing 105 g of 2-pyrrolidone and 29.9 g of a 18% N-methyl-2-pyrrolidone solution of polyamic acid, it was passed through a sieve with an opening of about 53 μm. Next, using a casting knife (Casting knife), the obtained mixed solution is coated on a PET film, and then dried at 60°C to obtain a film body composed of Li-type montmorillonite and polyamic acid and a PET film. A laminate composed of a film is formed. On the other hand, a stainless steel plate (outer diameter 120 mm, thickness 0.5 mm) electrolytically polished on both sides was prepared as a base material. This stainless steel plate is provided with a cylindrical hole having a diameter of 20 mm (tolerance ±0.05 mm) at the center. In addition, the electrolytic polishing area was a circle with a dia...

Embodiment 2

[0054] A standard gas barrier film was produced in the same manner as in Example 1, except that the diameter of the hole in the stainless steel plate was 6.5 mm (tolerance ±0.05 mm). A standard gas barrier film having a disk-shaped barrier layer with a diameter of about 30 mm and a thickness of about 30 μm in the center was obtained. The ratio of the maximum diameter of the opening of the stainless steel plate to the thickness of the barrier layer was 6.5 mm / 30 μm=217. In the case of measurement by a water vapor transmission rate measuring device with an effective diameter of 90mm, the water vapor transmission rate of the standard gas barrier film is 1.1×10 -5 g / m 2 / day.

Embodiment 3

[0056] A standard gas barrier film was produced in the same manner as in Example 1, except that the diameter of the hole in the stainless steel plate was 3.5 mm (tolerance ±0.05 mm). A standard gas barrier film having a disk-shaped barrier layer with a diameter of about 30 mm and a thickness of about 30 μm in the center was obtained. The ratio of the maximum diameter of the opening to the thickness of the barrier layer was 3.5 mm / 30 μm=117. In the case of measurement by a water vapor transmission rate measuring device with an effective diameter of 90mm, the water vapor transmission rate of the standard gas barrier film is 3.1×10 -6 g / m 2 / day.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap