Microchannel heat sink having special shunting structure

A technology of microchannels and flow channels, which is applied in cooling/ventilation/heating transformation, electrical equipment structural parts, electrical components, etc., can solve the problem of uneven flow distribution, achieve the effect of improving heat transfer uniformity and comprehensive ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The main content of the present invention is further illustrated below in conjunction with specific embodiments, but the content of the present invention is not limited to the following embodiments.

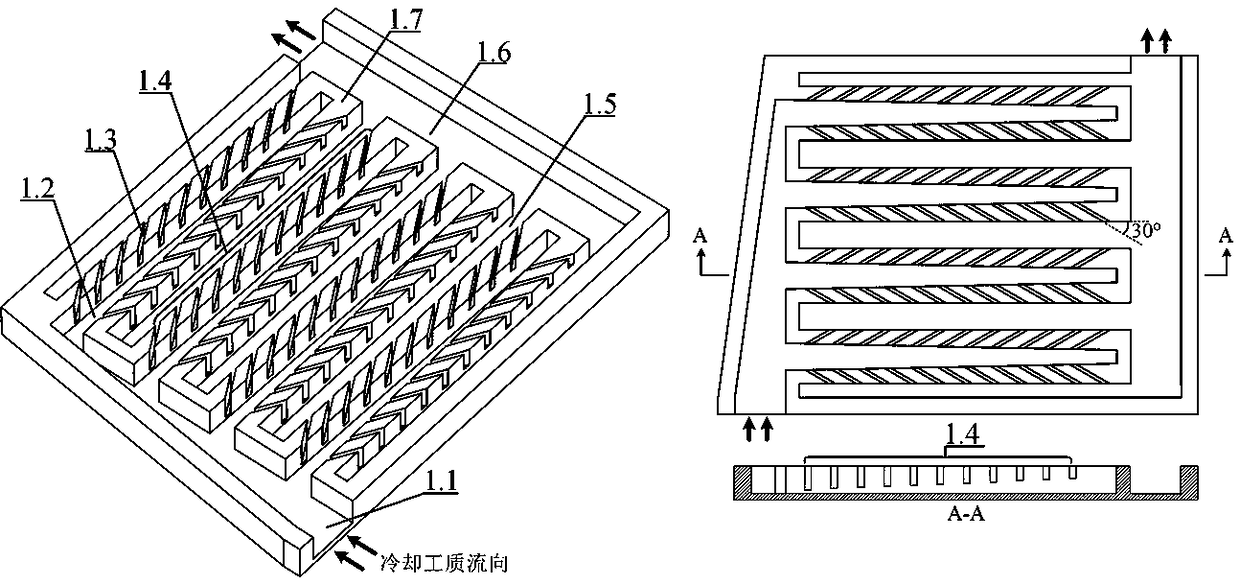

[0020] The invention discloses a microchannel heat sink with a special shunt structure, which comprises a shunt module and a soaking bottom plate directly contacting with a heat releasing device above it. The shunt module includes the main inflow channel (1.1), the shunt sub-channel (1.2), the overflow channel (1.3), the outflow sub-channel (1.5), and the main outflow channel (1.6). The main inlet channel (1.1) has a slope. The two side walls of the shunt sub-channel (1.2) are inclined toward the center to form a tapered channel structure. The overflow channel (1.3) is arranged obliquely; along the direction of the main flow in the inflow branch, the overflow channel (1.3) is highly non-linearly reduced (1.4).

[0021] In this embodiment, the main inflow channel (1.1) has a r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com