Hybrid reluctance type magnetically levitated linear motor with axial biased magnetic flux

A linear motor and hybrid technology, applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problems that limit the excellent performance of ordinary linear motors, and achieve the effects of low power consumption, safe and reliable work, and fewer failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

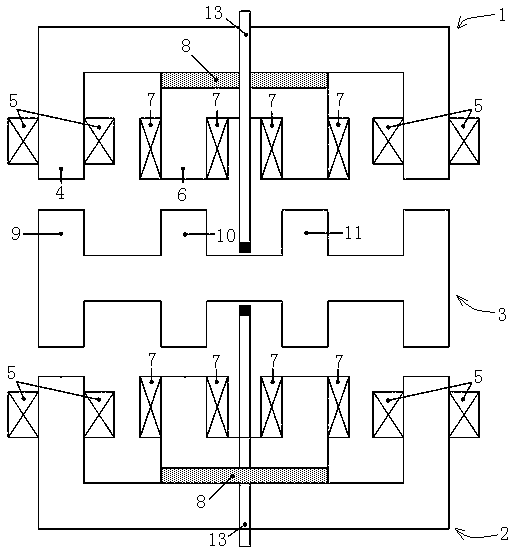

[0026] Attached below Figure 1-9 The technical scheme of the present invention is described in further detail.

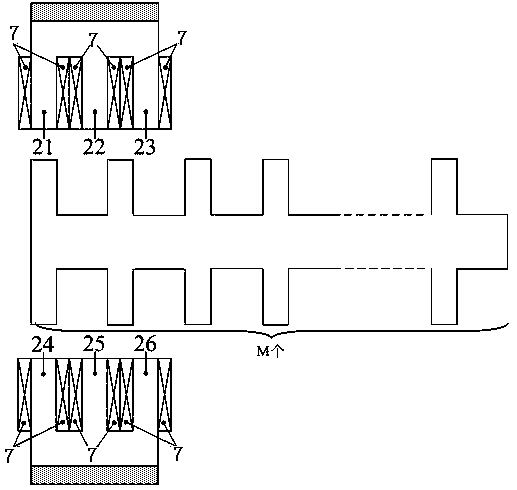

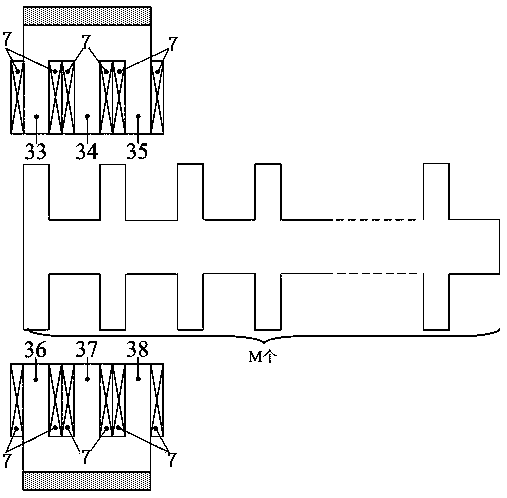

[0027] A hybrid reluctance magnetic levitation linear motor with axial bias flux, comprising an upper stator 1, a lower stator 2 and a mover 3, the axial length of the mover 3 is greater than the axial length of the upper and lower stators 1 and 2 length, the upper stator 1 includes a suspension core 4 whose front projection is in the shape of "冂", suspension windings 5 are wound on the two vertical bars of the suspension core 4, and a front projection is provided between the two vertical bars of the suspension core 4 An inverted "U"-shaped control core 6, the left and right vertical bars of the control core 6 are respectively wound with axial control windings 7, and the top of the control core 6 is connected with the suspension core 4 through a magnetic isolation aluminum block 8 , the lower stator 2 has the same structure as the upper stator 1 and is arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com