Industrial X-ray flaw detection-based welding defect negative assessment method for teaching

A technology of welding defects and X-rays, which is applied in the direction of material analysis using radiation, special data processing applications, instruments, etc., can solve the problems of slow speed, poor accuracy, manual evaluation, etc., and achieve the effect of fast speed and simple calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

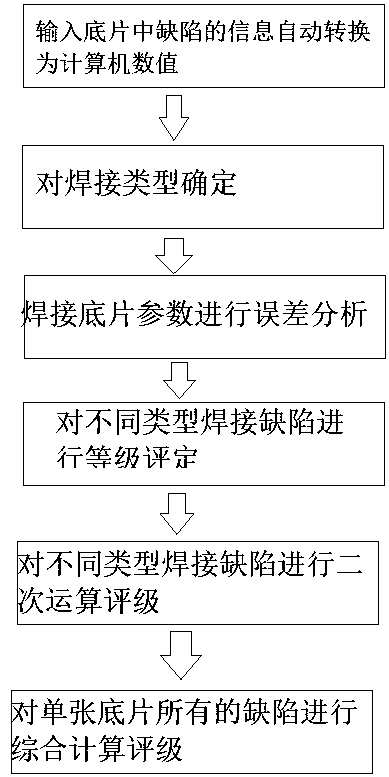

Method used

Image

Examples

specific Embodiment

[0032] Specific embodiment: two circular defects are arranged on a film, and the process of its assessment is:

[0033] Input: the thickness of the plate is 24, the long diameter of defect 1 is 4.1, and the long diameter of defect 2 is 3;

[0034] Evaluation process: the evaluation area is 10*10, 10 points for defect 1; 3 points for defect 2; the final point is 13;

[0035] The overall rating is level 3. The unit of the above-mentioned length is mm.

[0036] In actual operation, a defect with an aspect ratio less than or equal to 3 is defined as a circular defect. The circular defect can be round, oval, conical, or irregular in shape with a tail, including pores, slag inclusions, etc. and clip tungsten.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com