Sample cup transporting device based on analytical sampling equipment

A technology for analyzing sampling and transportation devices, which is applied in the direction of analysis materials, preparation of test samples, instruments, etc. It can solve the problems that the sample cups cannot be shaken and mixed at the same time, and the sample cups cannot be automatically clamped and released, etc., to achieve Facilitate high-speed automatic detection, realize seamless docking, and reduce workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

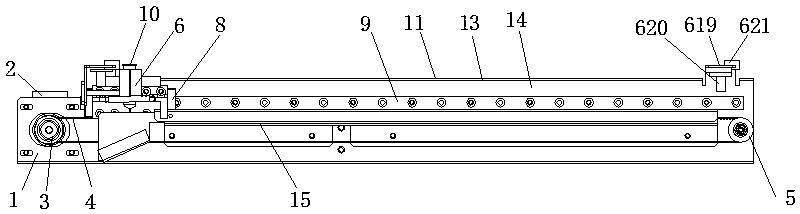

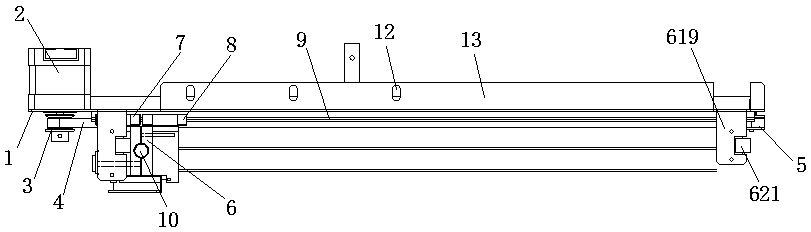

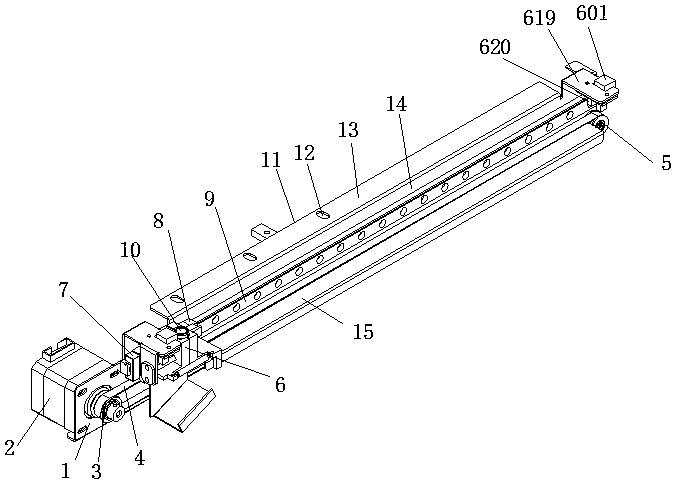

[0029] Such as Figure 1~4As shown, a sample cup transportation device based on analytical sampling equipment includes a frame 1, a driving motor 2, a driving wheel 3, a driven wheel 5 and a transmission belt 4, and the frame 1 is provided with a driving motor 2, Both ends of the frame 1 are respectively provided with a driving wheel 3 and a driven wheel 5, the driving wheel 3 is connected with the output end of the driving motor 2 through a rotating shaft, and the driven wheel 5 is arranged on the side of the frame 1 through a rotating shaft. At the other end, the transmission belt 4 is arranged on the driving wheel 3 and the driven wheel 5 and cooperates with the driving wheel 3 and the driven wheel 5 . The top of the transmission belt 4 is provided with a housing 11, the housing 11 is L-shaped, including a horizontal plate 13 and a vertical plate 14, the lower end of the vertical plate 14 is connected to the frame 1 by welding, and the upper end of the vertical plate 14 is ...

Embodiment 2

[0039] Such as Figure 1~4 As shown, a sample cup transportation device based on analytical sampling equipment includes a frame 1, a driving motor 2, a driving wheel 3, a driven wheel 5 and a transmission belt 4, and the frame 1 is provided with a driving motor 2, Both ends of the frame 1 are respectively provided with a driving wheel 3 and a driven wheel 5, the driving wheel 3 is connected with the output end of the driving motor 2 through a rotating shaft, and the driven wheel 5 is arranged on the side of the frame 1 through a rotating shaft. At the other end, the transmission belt 4 is arranged on the driving wheel 3 and the driven wheel 5 and cooperates with the driving wheel 3 and the driven wheel 5 . The top of the transmission belt 4 is provided with a casing 11, the casing 11 includes a horizontal plate 13 and a vertical plate 14, the lower end of the vertical plate 14 is welded to the frame 1, and the upper end of the vertical plate 14 is connected to the horizontal p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com