Fast simple and stable method for evaluating coaxiality based on double tolerance principle

A coaxiality and dual technology, applied in the direction of measuring devices, instruments, etc., can solve the problems of sensitivity to initial values, inability to take into account stability, speed and simple form at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

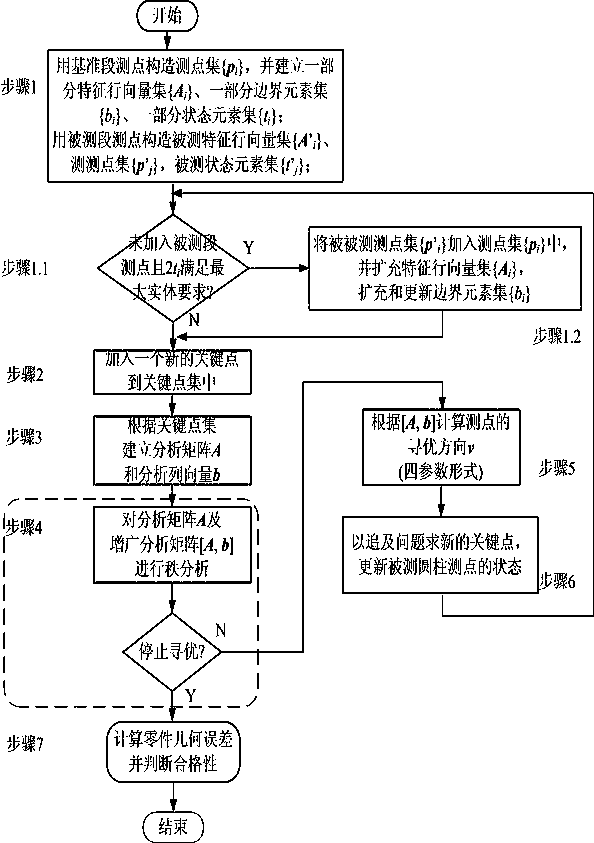

Method used

Image

Examples

Embodiment Construction

[0074] The following are specific embodiments of the present invention, and the solutions of the present invention will be further described with reference to the accompanying drawings, but the present invention is not limited to these embodiments.

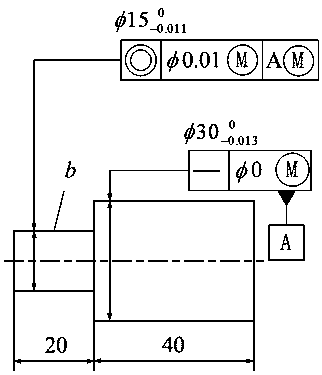

[0075] Assess the concentricity of a stepped shaft based on dual maximum entity requirements with tolerance design specifications such as figure 2 shown.

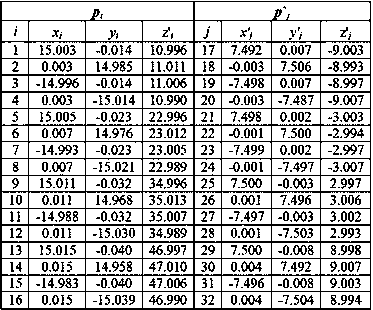

[0076] Step 1: Get the measurement point set of the reference segment { p i} and the measuring point set of the measured segment { p ' j}as follows:

[0077]

[0078] build state element set { t i} and the set of state elements under test { t ' j}as follows:

[0079]

[0080] build feature row vector set { A i}as follows:

[0081]

[0082] Create a set of feature row vectors to be tested { A ' j}as follows:

[0083]

[0084] build-boundary-element-set { b i}as follows:

[0085] { b i}=[1,1,1,1,1,1,1,1,1,1, 1,1,1,1,1,1] T .

[0086] After step 1, proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com