A Variable Inertial Vessel Based on Metamorphic Principle

A technology based on the principle of an inerter, applied in the direction of transmission, belt/chain/gear, non-rotational vibration suppression, etc., can solve the problems of difficult processing, low sensitivity, and time lag, and achieve high sensitivity, no time lag, and structural simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to better explain the present invention and facilitate understanding, the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

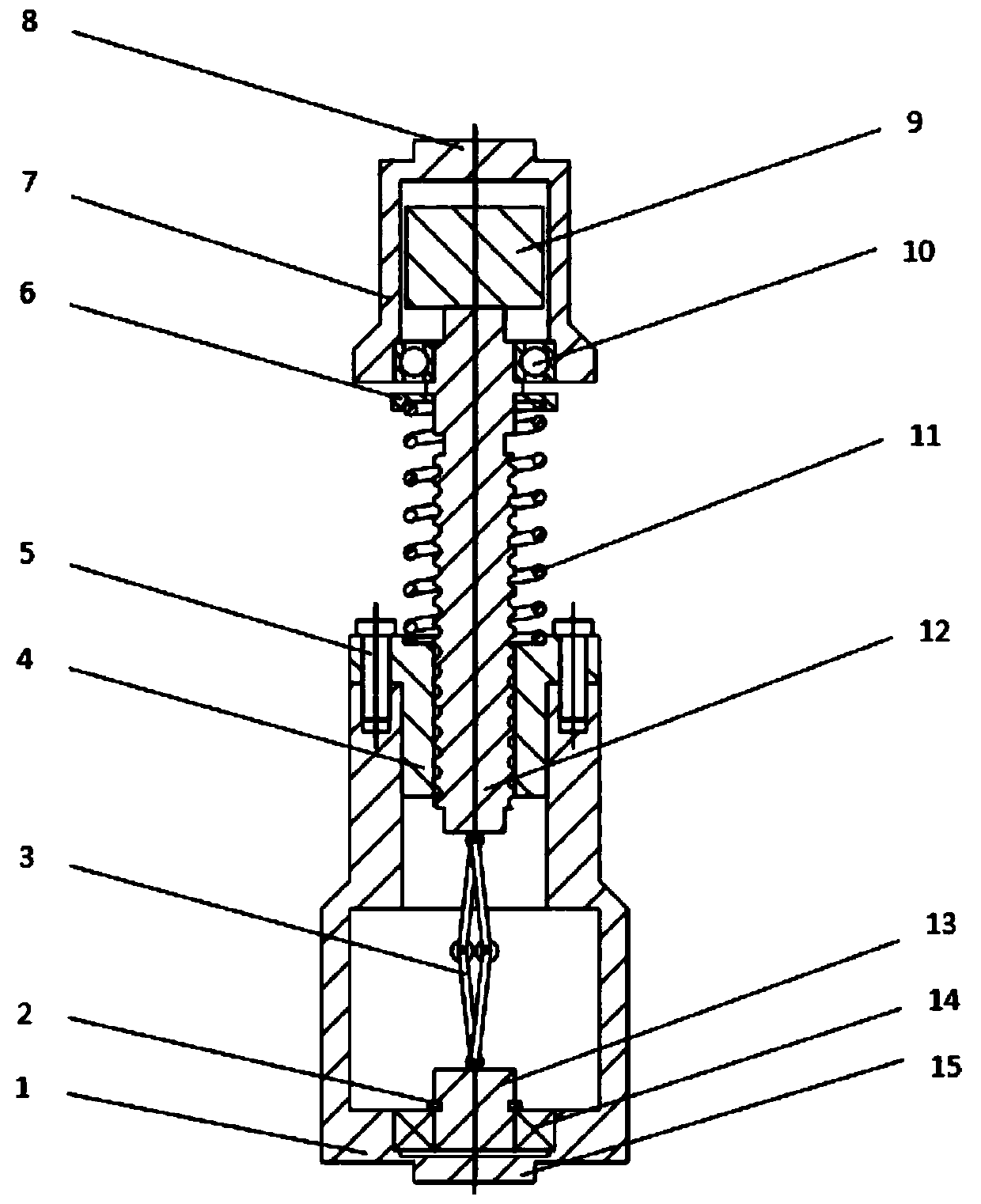

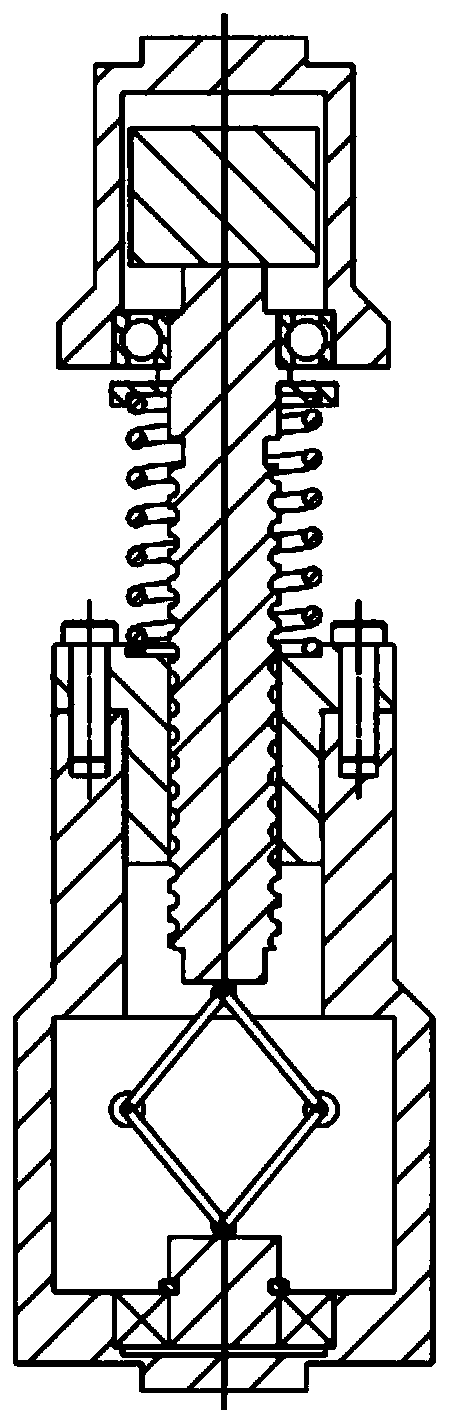

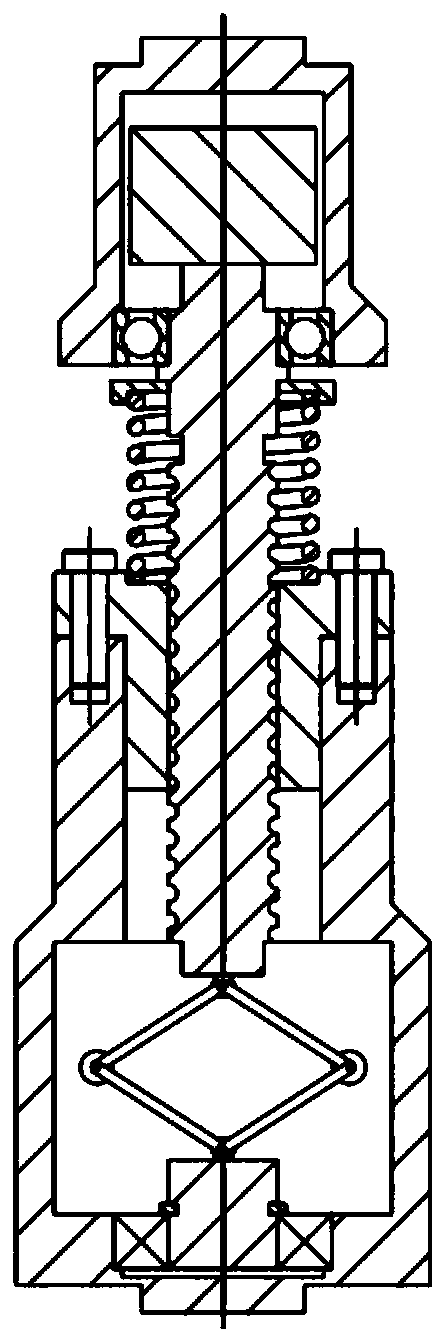

[0036] Such as Figure 1 to Figure 5 As shown, in this embodiment, a variable inertial inerter based on the metamorphic principle is provided, which includes an inerter main body, a spring 11 and a metamorphic mechanism 3 .

[0037] The main body of the inerter includes a flywheel chamber 7, a stroke chamber 1, a ball screw 12, a screw nut 4 and a flywheel 9, wherein the first end of the ball screw 12 extends into the flywheel chamber 7 and is rotatably connected with the flywheel chamber 7, located at The flywheel 9 in the flywheel chamber 7 is fixedly connected with the shaft end of the first end of the ball screw 12 , and the flywheel 9 rotates synchronously with the ball screw 12 .

[0038] The shifting mechanism 3 is arranged in the stroke chamber 1 , and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com