A flow-collecting and setting-sealing structure for small-flow eccentric water distributors without bridges in oilfields

A technology of eccentric water distribution and small flow, which is applied in the direction of measuring flow/mass flow, liquid/fluid solid measurement, instruments, etc., and can solve problems such as inability to inject liquid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

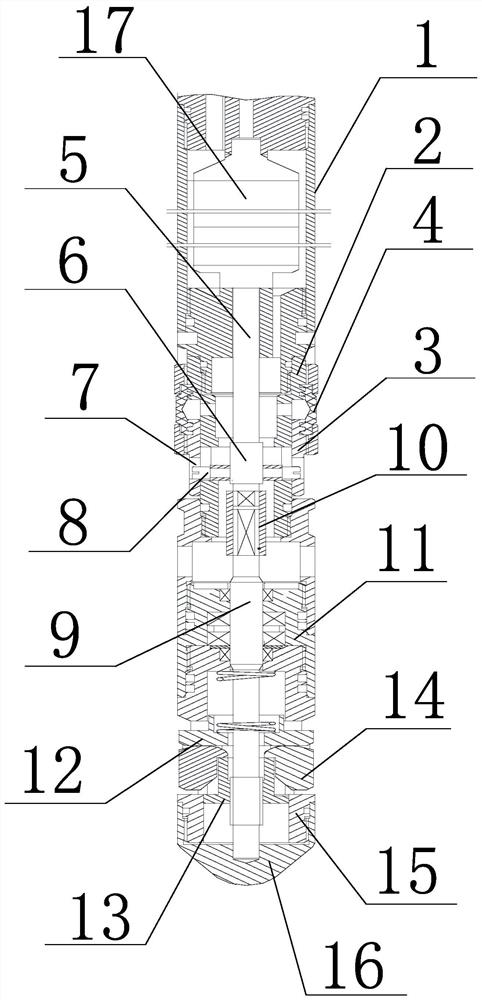

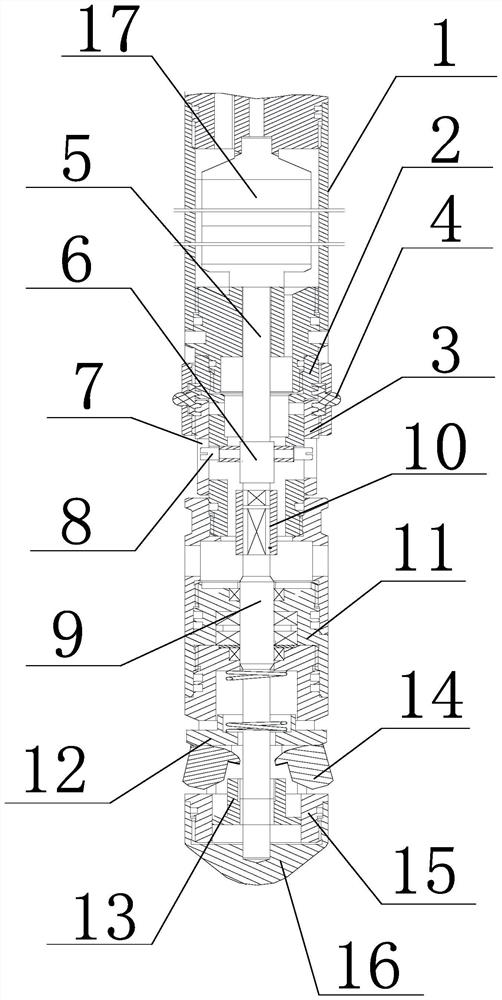

[0029] Such as figure 1 As shown, the present invention is a flow collection test sealing section for oil field small flow eccentric water distributor without bridge, including a test sealing section for eccentric water distributor with bridge, the top of the test sealing section is provided with a water inlet, A water outlet is provided at the bottom, and a liquid flow channel connecting the water inlet and the water outlet is provided inside the test sealing section.

[0030] The setting structure of the present invention, based on the structure of the existing test sealing section, provides a flow channel inside it, so that after the eccentric water distributor without a bridge is set, the smooth flow of the liquid flow is guaranteed without being blocked. Test the sealing section. The water distributor is a kind of equipment used in oil well water injection, and the test sealing section is to block the water distributor when testing the injection flow in the water distrib...

Embodiment 2

[0032] Such as figure 1 and figure 2 As shown, the present invention is a flow collecting test sealing section for small flow without bridge eccentric water distributor in the oil field. On the basis of Example 1, the test sealing section includes a shell cylinder 1, and the upper end of the shell cylinder 1 A water inlet is provided, and a water outlet is provided at the lower end. A compression fixing ring 2 and a compression push sleeve 3 are sequentially sleeved on the outer wall of the shell cylinder 1, and a useful For the set leather wrist 4, one end of the inner wall of the leather wrist 4 is connected with the outer wall of the compression fixing ring 2, and the other end of the inner wall of the leather wrist 4 is connected with the outer wall of the compression push sleeve 3, and the compression push sleeve 3 is in the Driven by the driving mechanism, it can move along the axis towards the compression fixing ring 2. When the compression push sleeve 3 moves towards...

Embodiment 3

[0035] Such as figure 1 and figure 2 As shown, the present invention is a kind of flow collecting test sealing section for oilfield small flow without bridge eccentric water distributor. On the basis of Embodiment 2, the driving mechanism includes a driving motor 17 arranged below the water inlet in the shell cylinder 1 , the lower end of the drive motor is connected with the first transmission shaft 5 coaxial with the shell cylinder 1, the first transmission shaft 5 is provided with a translation guide sleeve 6 through a threaded sub-set, and the outer wall of the translation guide sleeve 6 is vertically connected with a movable The pin 8 is provided with a bar-shaped moving hole 7 parallel to the axis of the shell cylinder 1 on the outer wall of the shell cylinder 1. The moving hole 7 is located between the translation guide sleeve 6 and the compression push sleeve 3. The end of the movable pin 8 extends Out of the moving hole 7 and flush with the outer wall of the compres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com