Snow melting vehicle

A technology for snow melting and car body, applied in snow surface cleaning, construction, cleaning methods, etc., can solve the problems of inconvenient cleaning, waste of manpower and material resources, affecting road smoothness, etc. The effect of high consumption and work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

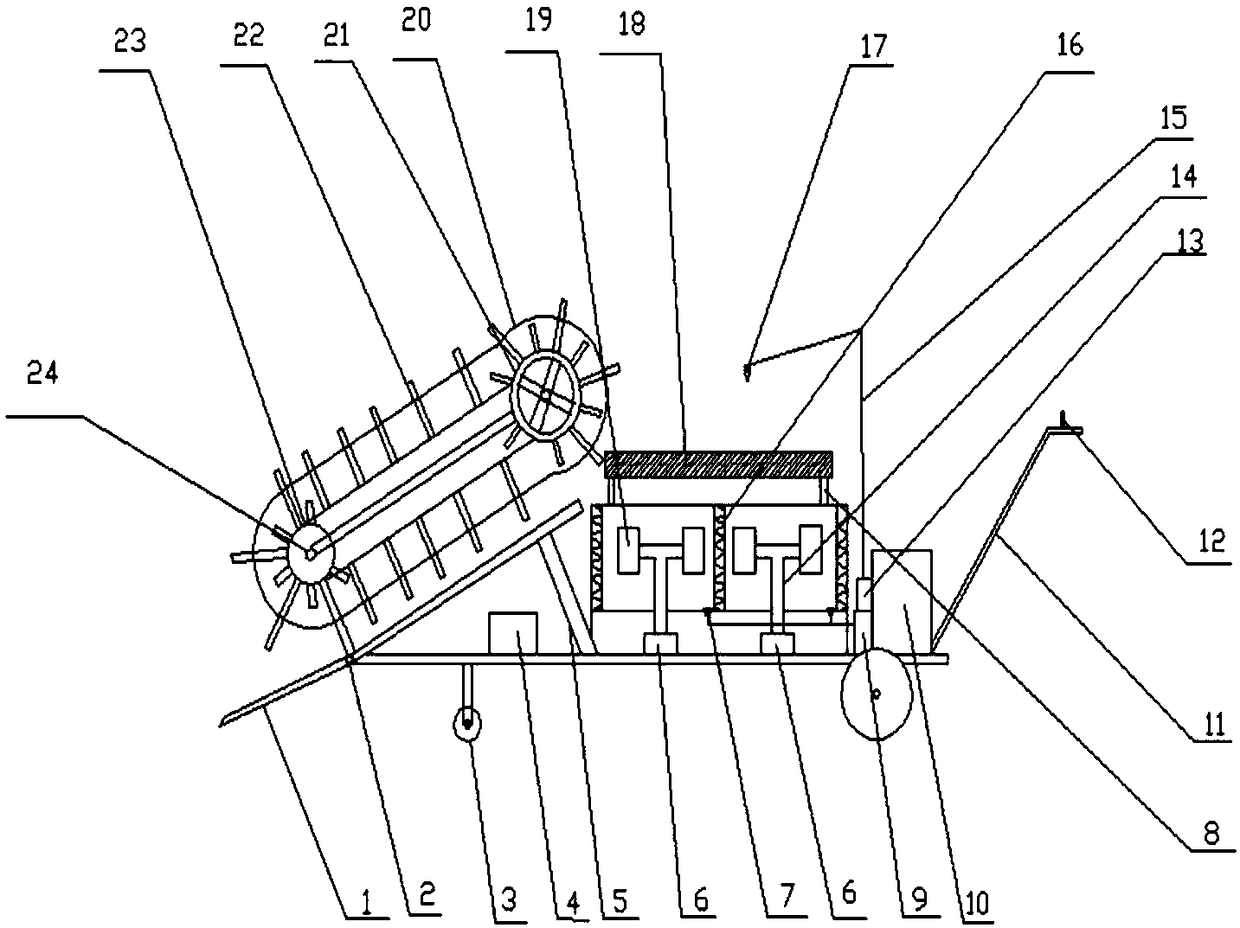

[0018] The present invention will be further described below in conjunction with the drawings:

[0019] See figure 1 with figure 2 , A snow melting vehicle, including a vehicle body, a bucket 1, a snow transport device, a snow melting device, a water spray device, a power source 4, and an engine 10; the bucket 1 is arranged at one end of the vehicle body, and the vehicle body at one end of the bucket 1 is provided The upper surface is provided with a snow transport device, and the upper surface of the vehicle body on the side of the snow transport device is provided with a snow melting device. The snow transported by the snow transport device falls on the snow melting device; the upper surface of the vehicle body on the side of the snow melting device is provided with a water spray device to melt snow The device is connected to a water spray device; the water outlet of the water spray device is arranged above the snow melting device; the engine 10 is arranged on the upper surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com