Low-sodium lactic acid spicy cabbage made from fermentation of cichorium intybus and fermenting making method of low-sodium lactic acid spicy cabbage

A technology for chicory and cabbage, which is applied in the directions of microorganism-based methods, biochemical equipment and methods, bacteria used in food preparation, etc. Growth and other problems, to achieve the effect of enhancing human immunity and resistance, improving gastrointestinal function, and preventing gastrointestinal diseases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

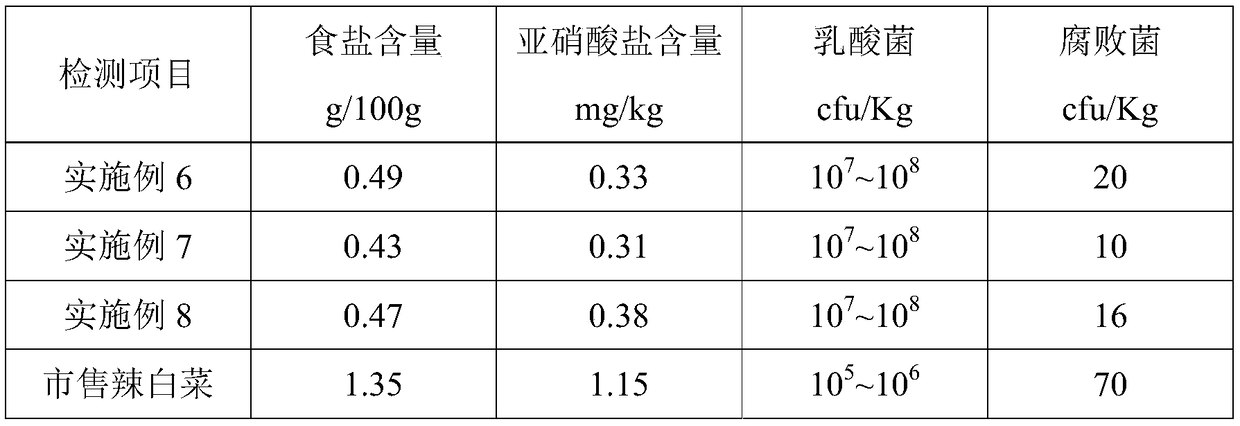

Examples

Embodiment 1

[0031] A kind of fermentation production method of the low-sodium lactic acid spicy cabbage that utilizes chicory fermentation to produce, described fermentation production method steps are as follows:

[0032] Step 1, preparation of chicory fermented liquid

[0033] (1) Crush the chicory root with a moisture content of 10-15% to 60-100 meshes, soak the chicory powder in water according to the weight ratio of 1:3-4, and obtain a chicory slurry with a pH value of 5.5 after homogenization ;

[0034](2) Add a certain amount of sucrose, corn peptide and sodium sulfate to the obtained chicory slurry, stir and insert the compound lactic acid bacteria seed liquid by a certain volume fraction, ferment at a certain fermentation temperature and stirring speed, when the pH of the fermented liquid When the pH value drops to 5.0 and the reducing sugar content is lower than 1.5%, the fermentation is terminated, and a chicory fermentation broth with a pH value of 4.7-5 is obtained;

[0035...

Embodiment 2

[0042] A kind of fermentation production method of the low-sodium lactic acid spicy cabbage that utilizes chicory fermentation to produce, described fermentation production method steps are as follows:

[0043] Step 1, preparation of chicory fermented liquid

[0044] (1) Crush the chicory root with a moisture content of 10-15% to 60-100 meshes, soak the chicory powder in water according to the weight ratio of 1:3-4, and obtain a chicory slurry with a pH value of 5.5 after homogenization ;

[0045] (2) Add 5-8% sucrose of chicory slurry quality in the gained chicory slurry, 1-3% corn peptide and 0.15-0.2% sodium sulfate, insert the compound lactic acid bacteria of chicory slurry volume 0.1-0.5% after stirring For seed liquid, the fermentation temperature is 23-27°C, and the stirring speed is 100-120r / min for fermentation. When the pH value of the fermentation liquid drops to 5.0 and the reducing sugar content is lower than 1.5%, the fermentation ends, and the obtained pH value...

Embodiment 3

[0053] A kind of fermentation production method of the low-sodium lactic acid spicy cabbage that utilizes chicory fermentation to produce, described fermentation production method steps are as follows:

[0054] Step 1, preparation of chicory fermented liquid

[0055] (1) Crush the chicory root with a moisture content of 10-15% to 60-100 meshes, soak the chicory powder in water according to the weight ratio of 1:3-4, and obtain a chicory slurry with a pH value of 5.5 after homogenization ;

[0056] (2) Add 5-8% sucrose of chicory slurry quality in the gained chicory slurry, 1-3% corn peptide and 0.15-0.2% sodium sulfate, insert the compound lactic acid bacteria of chicory slurry volume 0.1-0.5% after stirring For seed liquid, the fermentation temperature is 23-27°C, and the stirring speed is 100-120r / min for fermentation. When the pH value of the fermentation liquid drops to 5.0 and the reducing sugar content is lower than 1.5%, the fermentation ends, and the obtained pH value...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com