Underwater explosion shock resistant coating material, preparation method and application of material

A technology of underwater explosion and coating materials, which is applied in coatings, polyurea/polyurethane coatings, etc., can solve the problems that the protection performance of active ships cannot be improved, and achieve the effect of improving dynamic mechanical properties and rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

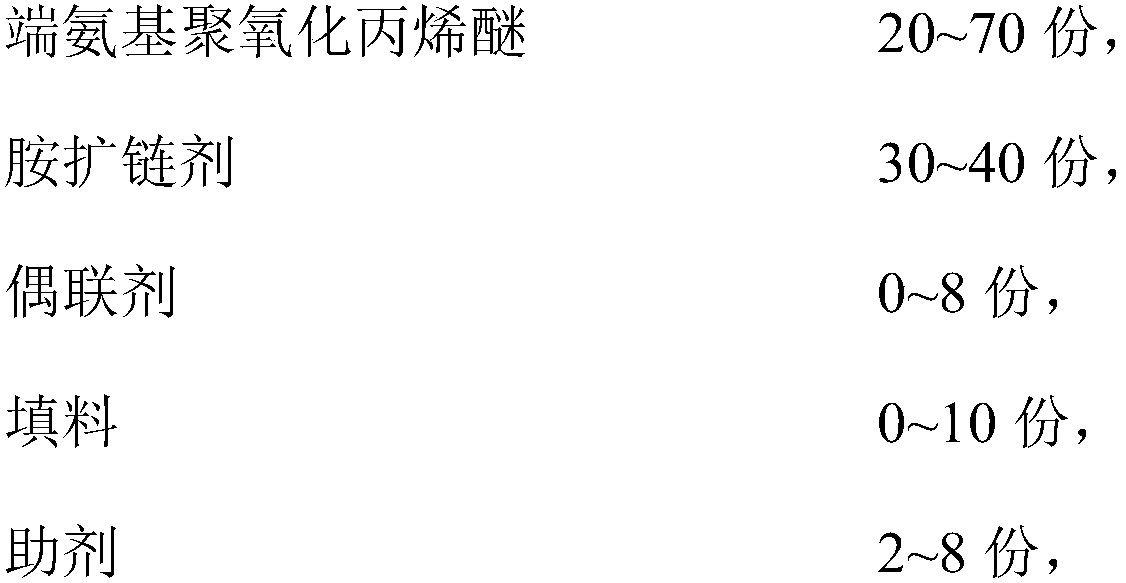

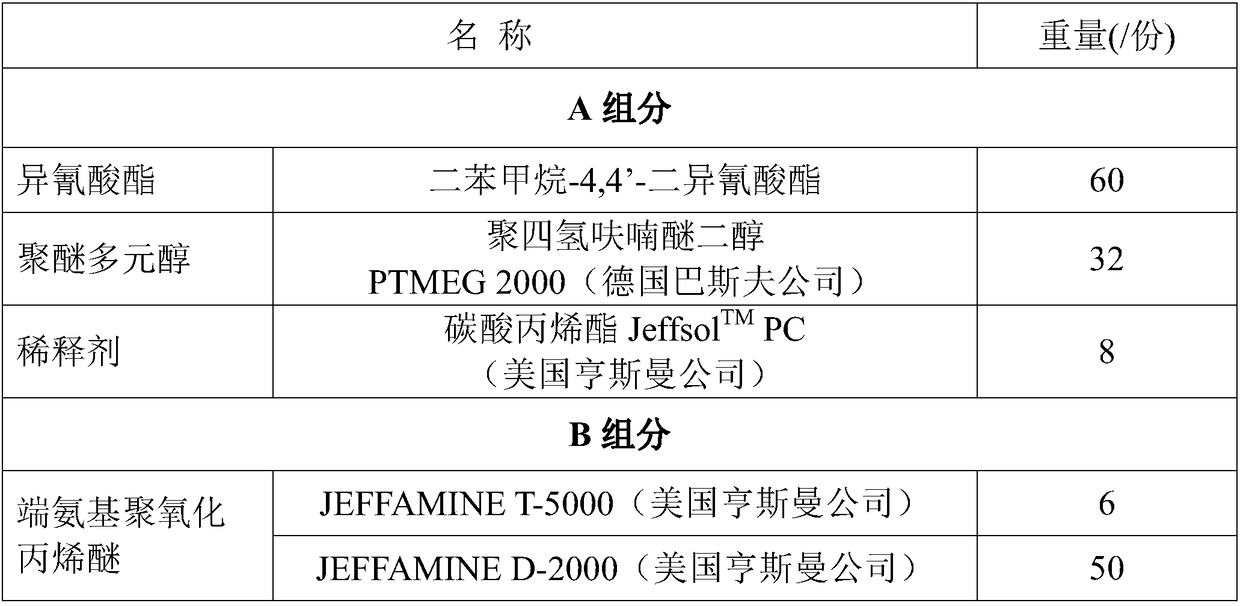

[0037] An anti-underwater explosion impact coating material is composed of A component and B component, and its composition and mass parts are shown in Table 1.

[0038] Table 1

[0039]

[0040]

[0041] A kind of preparation method of anti-underwater explosion impact coating material of the present invention, described method step is as follows:

[0042] (1) Add polytetrahydrofuran ether glycol into reaction kettle Ⅰ with nitrogen protection, heat to 120°C under stirring, dehydrate under vacuum -0.05MPa for 2 hours, remove the vacuum, and add diphenylmethane- 4,4'-diisocyanate, react at 110°C for 2.5 hours, cool down to below 60°C, add propylene carbonate, stir well to obtain component A.

[0043] (2) The amino-terminated polyoxypropylene ether JEFFAMINE T-5000, the amino-terminated polyoxypropylene ether JEFFAMINED-2000, the amino-terminated polyoxypropylene ether JEFFAMINE D-400, the amine chain extender diethyltoluene diamine, and the coupling agent Add Z6040, fil...

Embodiment 2

[0054] The anti-underwater explosion impact coating material and its preparation method described in this embodiment are the same as those in Embodiment 1.

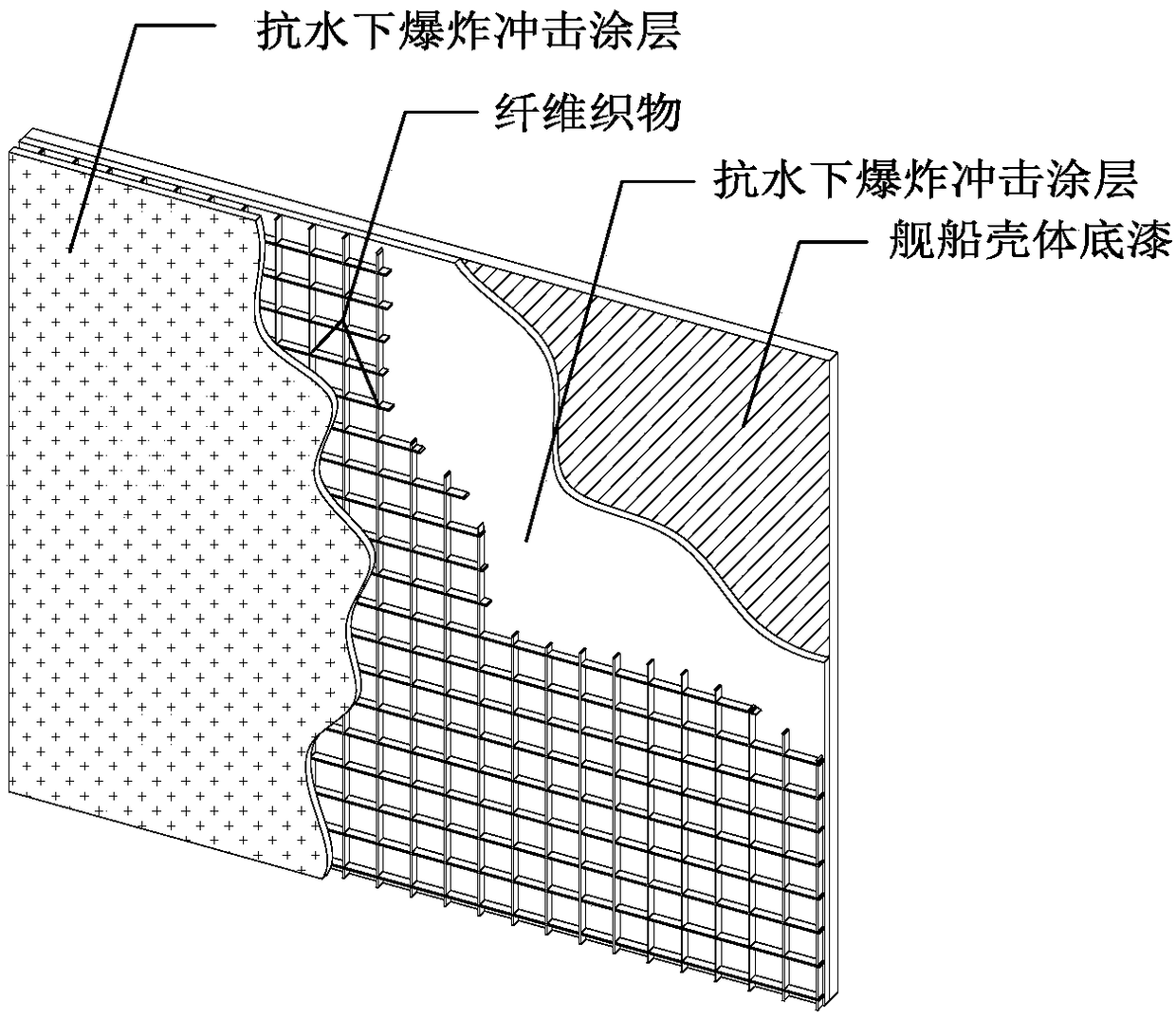

[0055] A kind of application of the anti-underwater explosion impact coating material described in this embodiment: the H-20 / 35 spraying equipment produced by GUSMER is used for spraying construction, and the two components of A and B are separated from the material barrel according to the volume by the respective pumps. The ratio of 1:1 is sent to the host for metering, pressurization, temperature rise, and then sent to the spray gun. The flow of materials in the spray gun is absolutely controlled and free flow is not allowed, so that the materials are mixed in the mixing chamber of the spray gun in the fastest way, and then sprayed on the primer on the surface of the ship hull to form a layer of anti-underwater explosion Impact coating with a thickness of 6mm, then covered with a layer of fiber fabric, and then sprayed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com