Buffer constant-tension device for online fiber unfolding and application method thereof

A technology of constant tension and fiber use, which is applied in the directions of transportation and packaging, thin material processing, winding strips, etc. The transmission speed is fast, the response is timely, and the effect of preventing the speed from being out of sync

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation, features and effects of the online fiber-spreading buffer constant tension device and its method of use proposed according to the present invention are described in detail as follows: back.

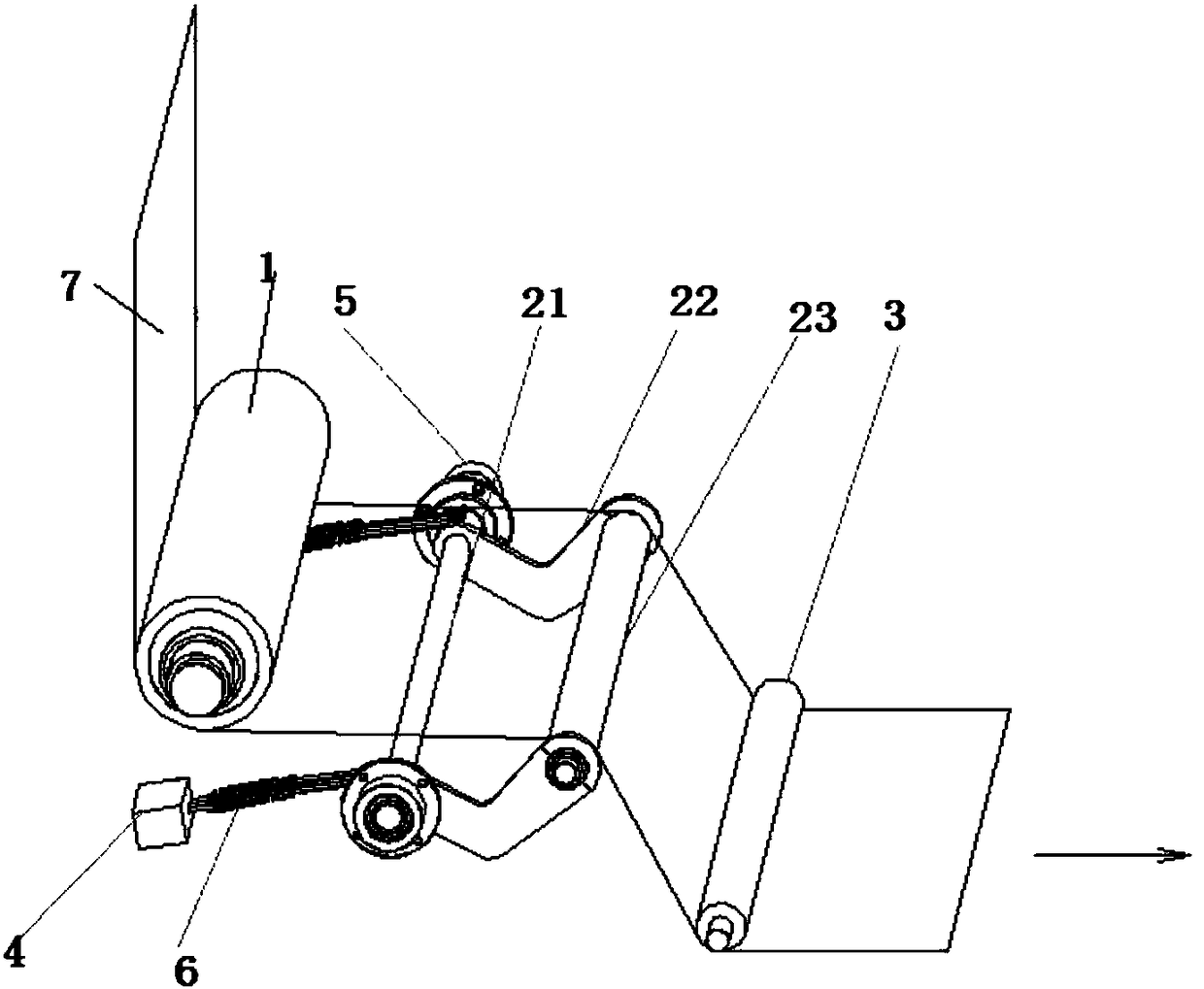

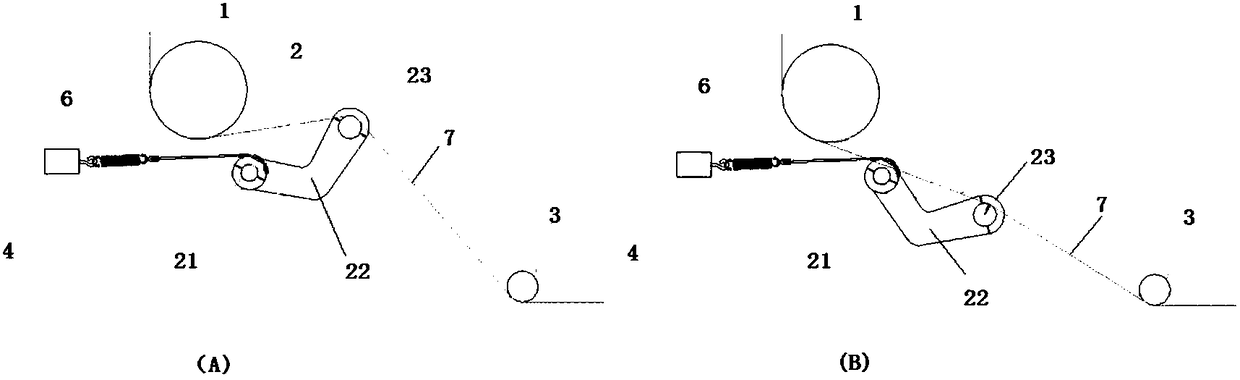

[0033] like figure 1 As shown, the present invention discloses a buffer constant tension device for online fiber spreading, including:

[0034] The roller assembly includes driving roller 1, swing roller 2 and fixed transition roller 3. The central axes of the three groups of driving roller 1, swing roller 2 and fixed transition roller 3 are respectively arranged in parallel and distributed in a triangle, wherein the swing roller 2 includes a fixed set The swing arm mandrel 21 of the swing arm mandrel 21, the swing arm 22 that is rotatably connected with the swing arm mandrel 21, and the swing roller main body 23 arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com