A driving cam for lifting the moving platform of die-cutting equipment and its die-cutting equipment

A technology for driving cams and moving platforms, which is applied in metal processing and other directions, and can solve the problems of large wear of the transmission mechanism, affecting the speed and effect of deep embossing and bronzing products, so as to ensure stable operation of the equipment, improve speed and effect, and improve Effects on production efficiency and production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

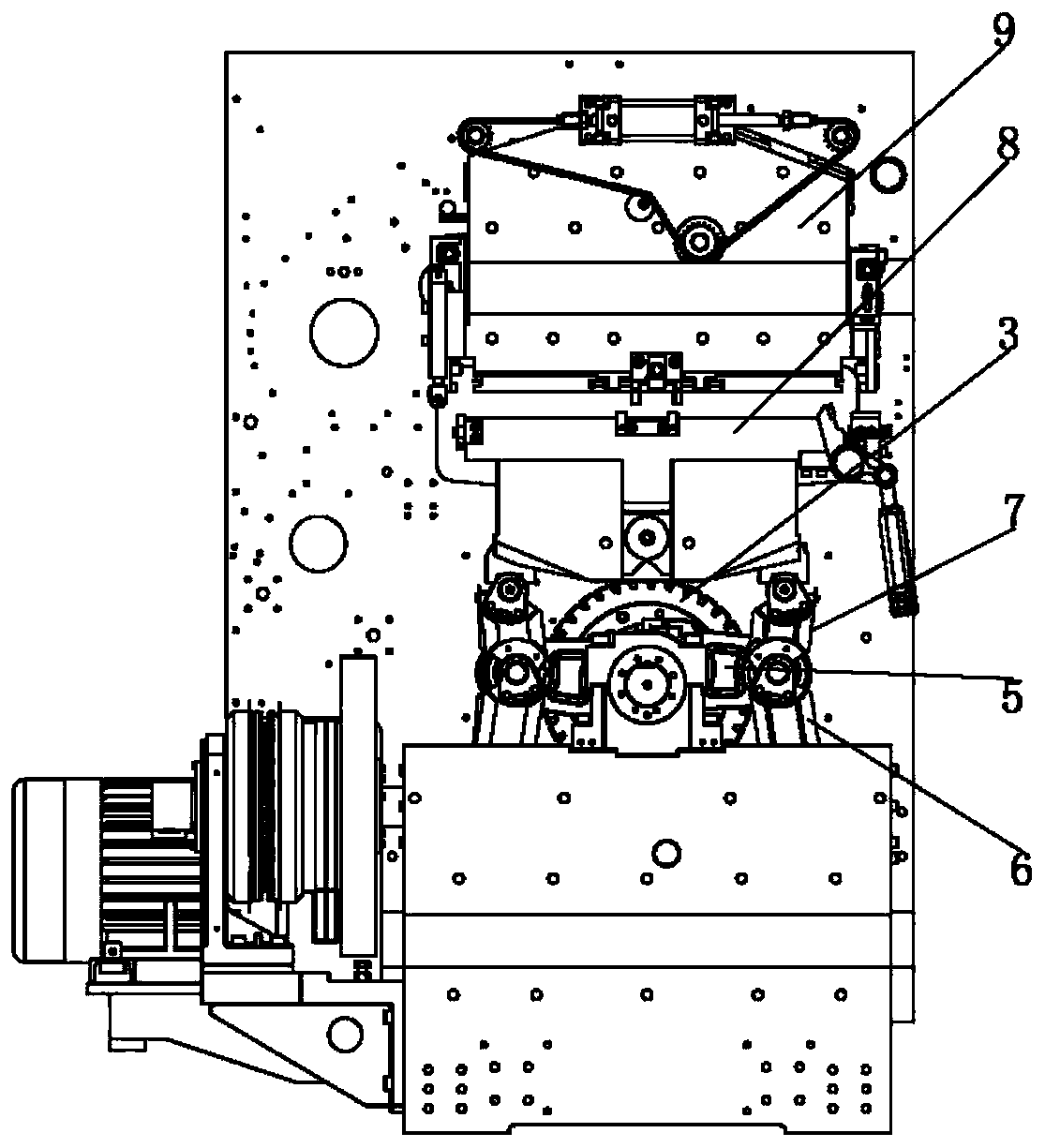

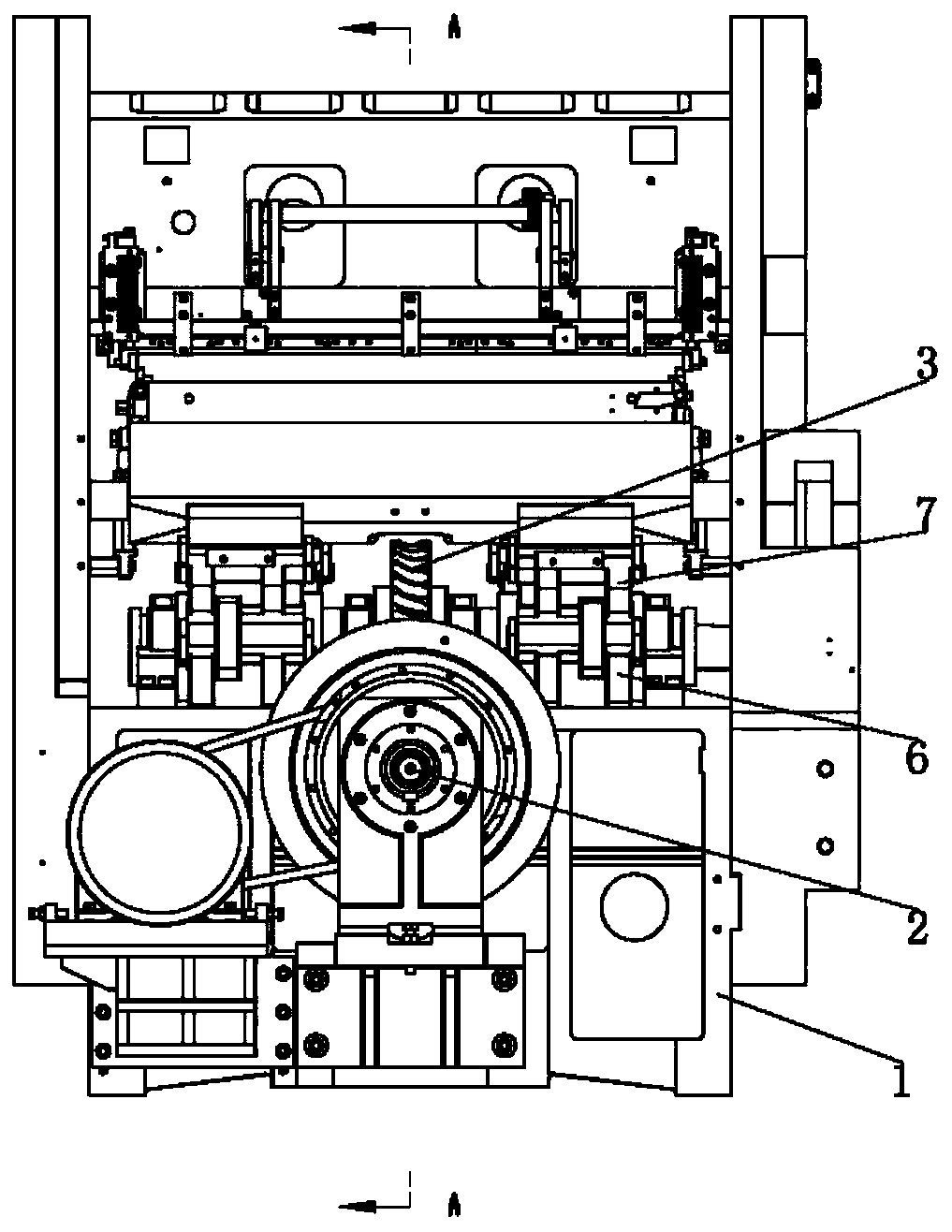

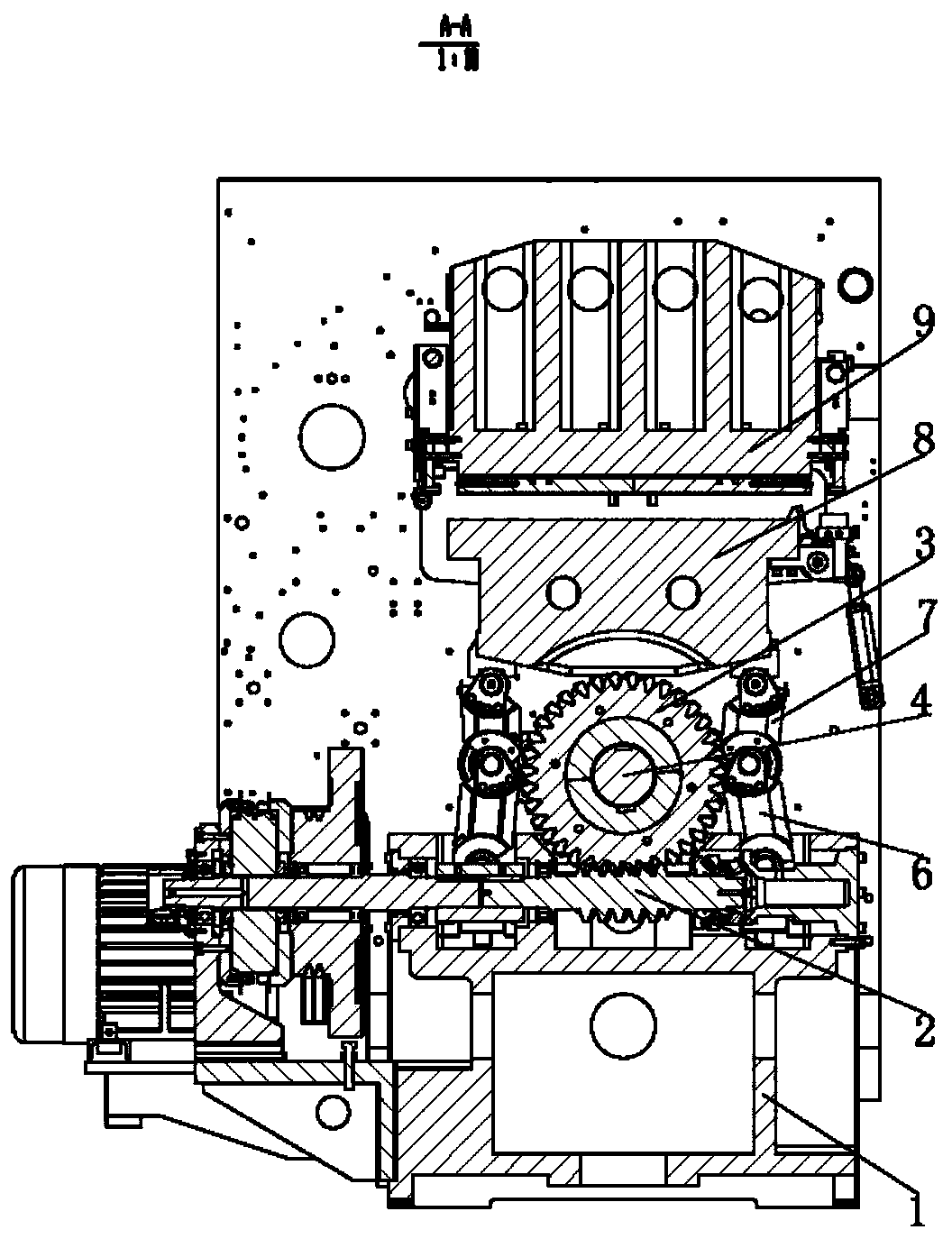

[0099] Such as Figure 5 to Figure 8 As shown, this embodiment provides a driving cam 10 for lifting the movable platform 8 of the die-cutting equipment, including a cam body 10-1, and the outline of the cam body 10-1 has an ascending curve 10-1-1 and A descending curve 10-1-2, a far-end resting curve 10-1-3 is connected between the distal end of the ascending curve 10-1-1 and the distal end of the descending curve 10-1-2.

[0100] Various improvements of this embodiment are described in detail below.

[0101] Such as Figure 5 As shown, the central angle corresponding to the distal rest curve 10-1-3 is 20 degrees. Of course, it may also be that the central angle corresponding to the distal rest curve 10-1-3 is 10 degrees. Alternatively, the central angle corresponding to the distal rest curve 10-1-3 is 30 degrees.

[0102] Such as Figure 5 with Figure 8 As shown, a near-end resting curve 10-1-4 is connected between the proximal end of the rising curve 10-1-1 and the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com