Method for conducting virtual simulation on breaker assembly robot

A technology of circuit breaker assembly and virtual simulation, applied in the directions of instruments, manipulators, program-controlled manipulators, etc., can solve problems such as comparison and display of calculation results without models, restricting product performance and efficiency, and numerous logical relationships, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

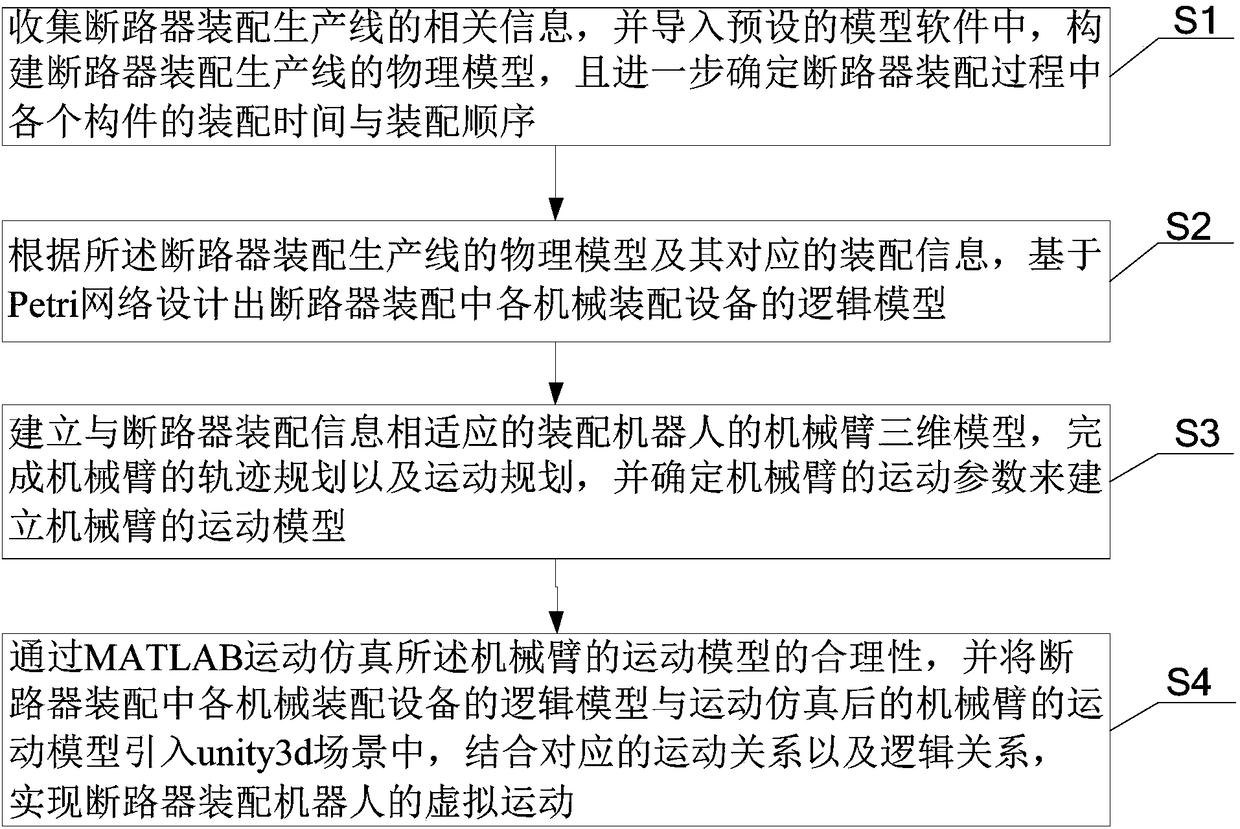

[0050] Such as figure 1 As shown, in the embodiment of the present invention, a method for virtual simulation of a circuit breaker assembly robot is provided, and the method includes:

[0051] Step S1, collect the relevant information of the circuit breaker assembly line, and import it into the preset model software to construct the physical model of the circuit breaker assembly line, and further determine the assembly time and assembly sequence of each component in the circuit breaker assembly process;

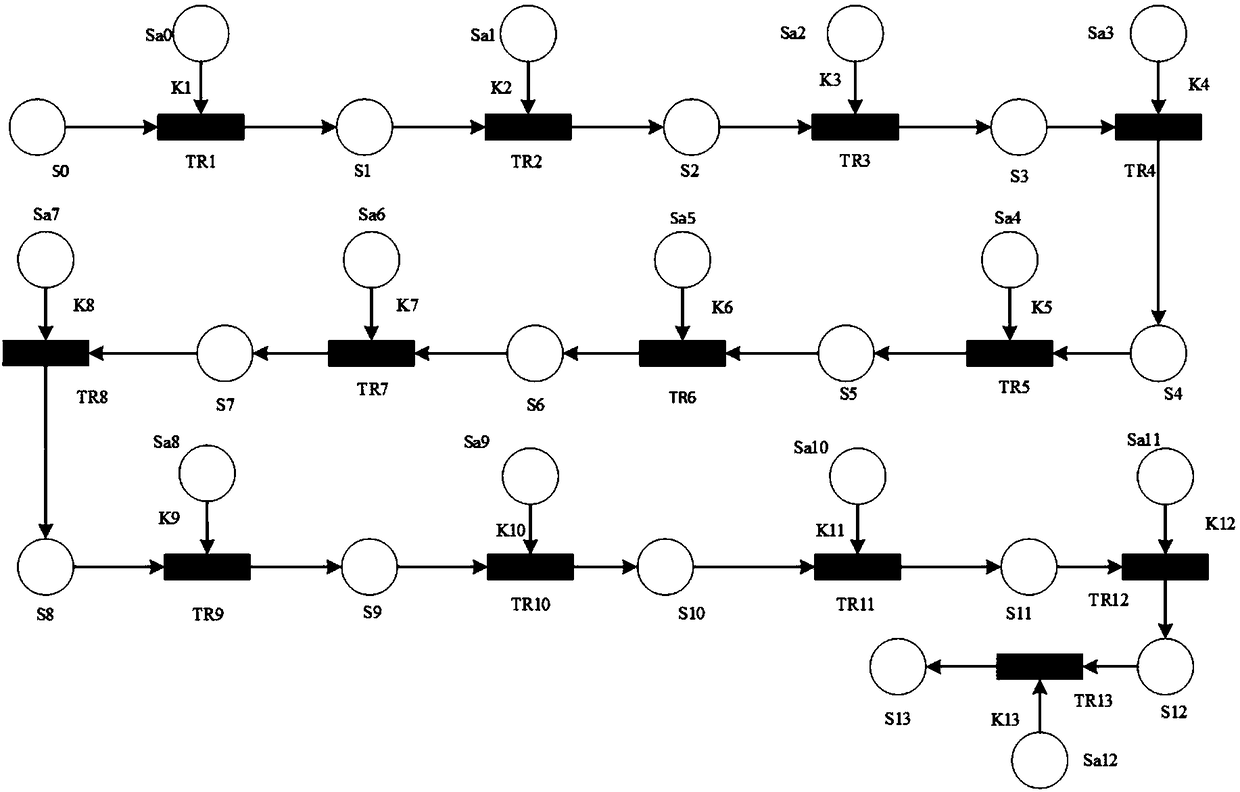

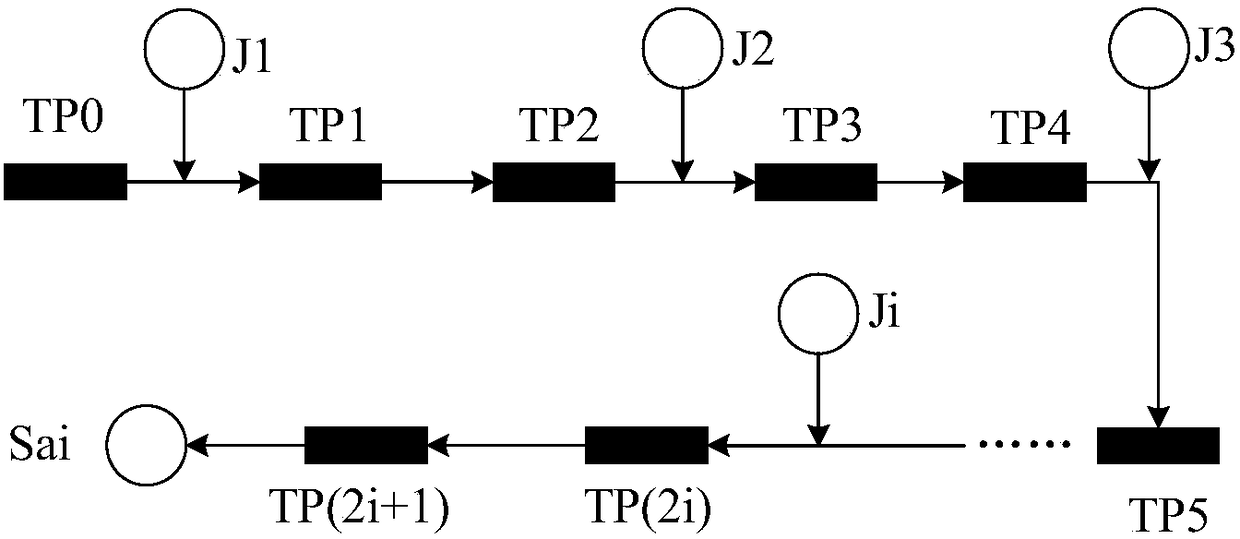

[0052] Step S2, according to the physical model of the circuit breaker assembly line and its corresponding assembly information, based on the Petri network design the logic model of each mechanical assembly equipment in the circuit breaker assembly;

[0053] Ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com