Water mist spraying connecting device for ship cargo hold

A connecting device and cargo hold technology, which is applied in the field of ships, can solve the problems of increasing the difficulty of loading and unloading operations, the inability to stack goods at the hose, and the loss of cargo space in the cargo hold, so as to reduce the risk of fusing, reduce the difficulty of operation, and increase the loading capacity. cargo space effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] A preferred embodiment will be given below, and the present invention will be described more clearly and completely in conjunction with the accompanying drawings.

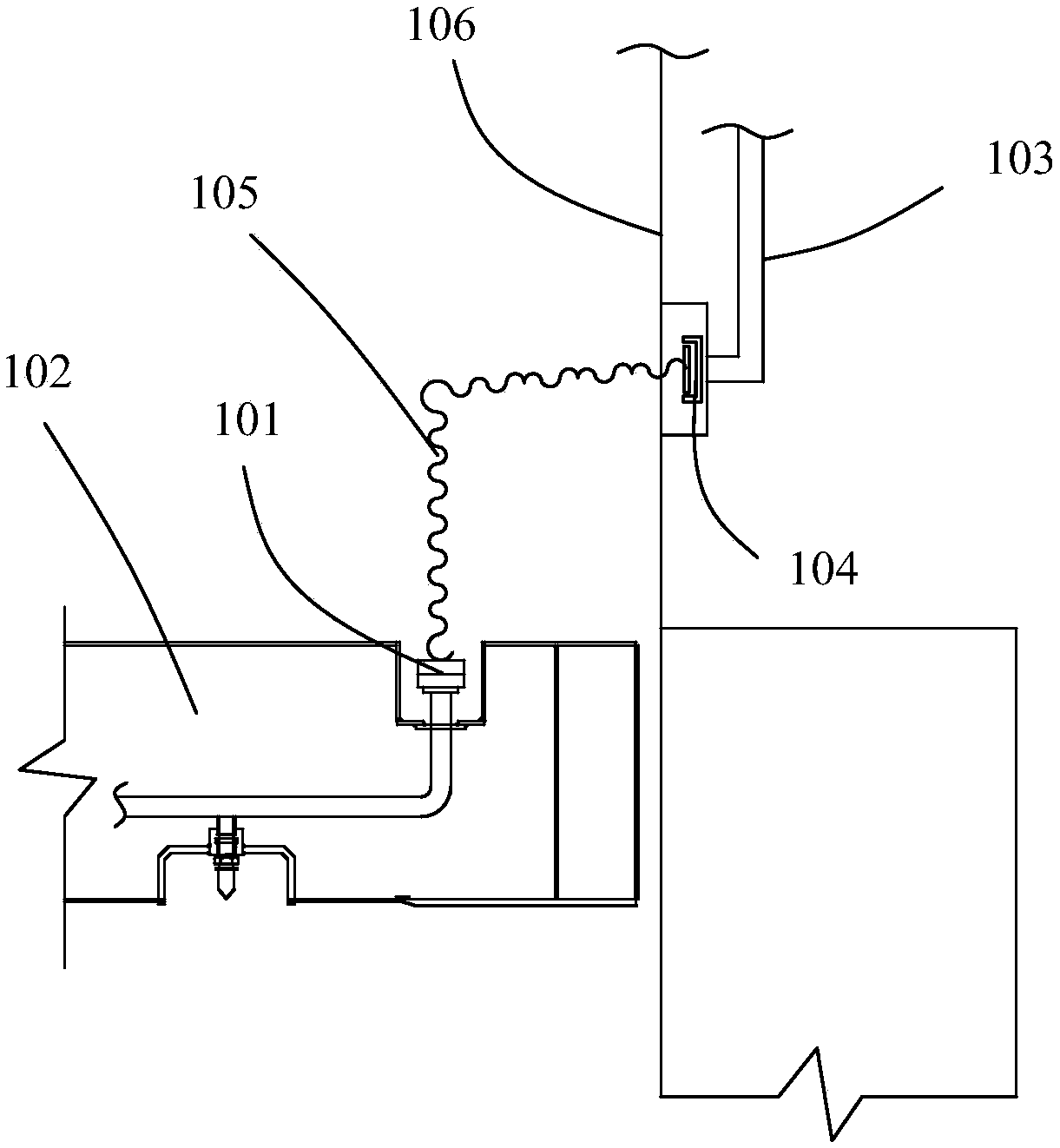

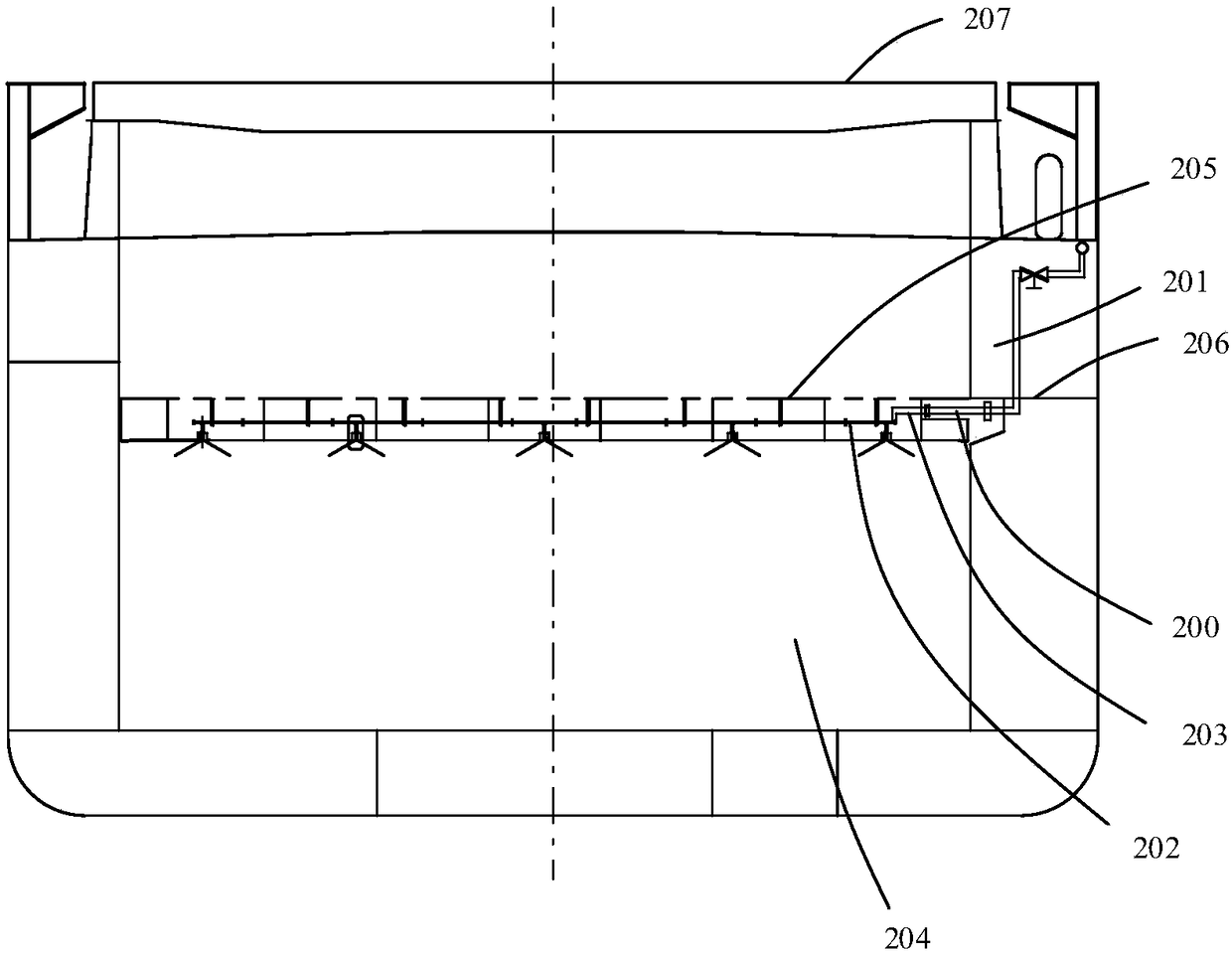

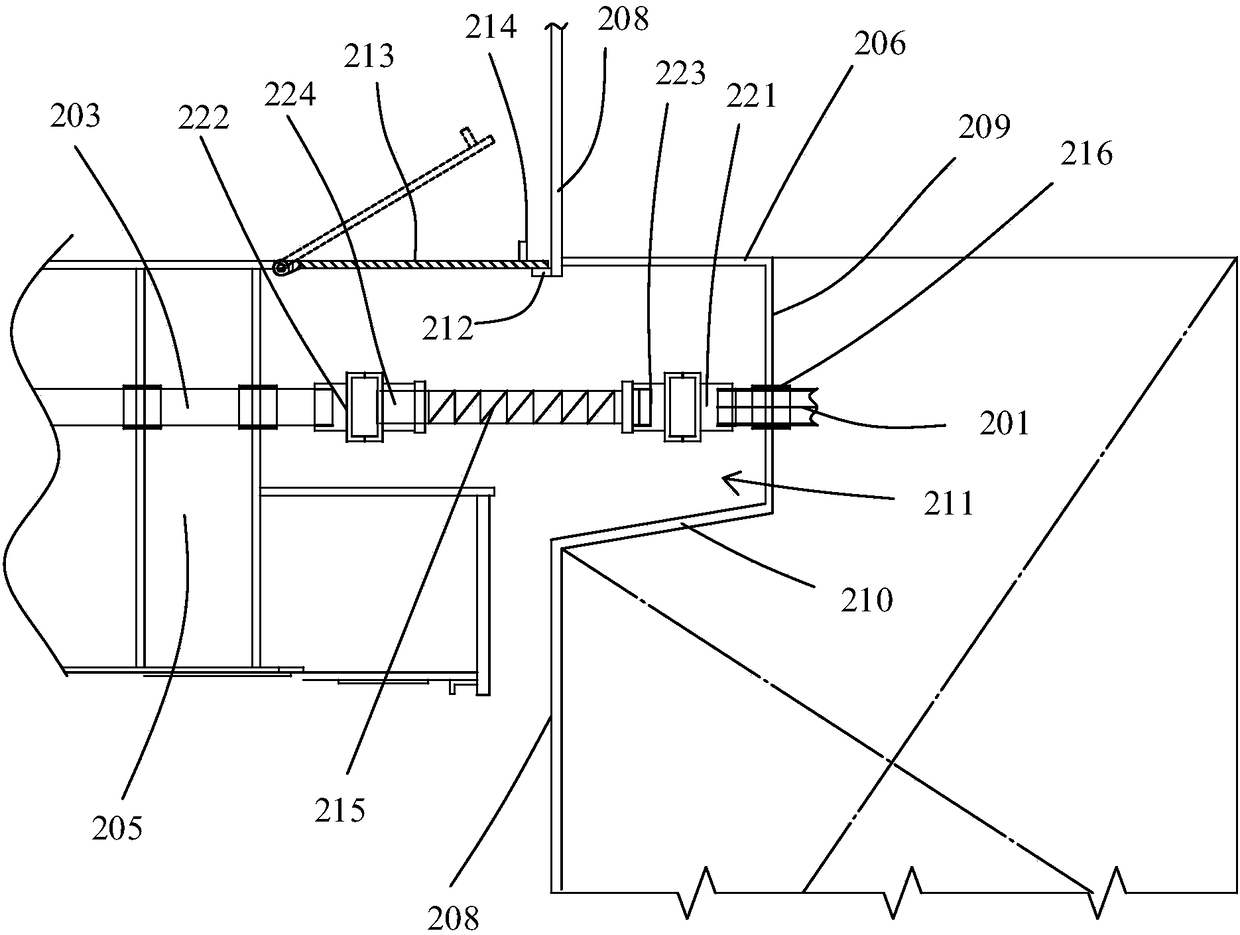

[0024] Such as figure 2 and image 3 As shown, a ship cargo hold water mist spray connection device 200 is arranged between the water outlet pipe 201 of the main fire protection system and the water inlet pipe 203 of the cargo hold water mist spray system 202, and the cargo hold water mist spray system 202 is located in the cargo hold In the hatch cover 205 of 204, hatch cover 205 is located on the second deck 206 of cargo hold, and second deck 206 is positioned at the middle part of the cargo wall 208 of cargo hold 204. On top of the cargo hold 204 is a hatch deck 207 .

[0025] The cargo wall 208 is provided with a hollow portion below the second deck 206 , and an inner bulkhead 209 and a sloping plate 210 are arranged in the hollow portion, and the inner bulkhead 209 is fixed on the lower end surface o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com