Auxiliary display screen film-laminating equipment for machining and producing liquid crystal display module

A liquid crystal display module and display technology, applied in nonlinear optics, instruments, optics, etc., can solve the problems of inconvenient discharge of film-coated bubbles, high usage limitations, and inconvenient fixation, and reduce usage limitations. , the effect of improving adaptability and improving practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

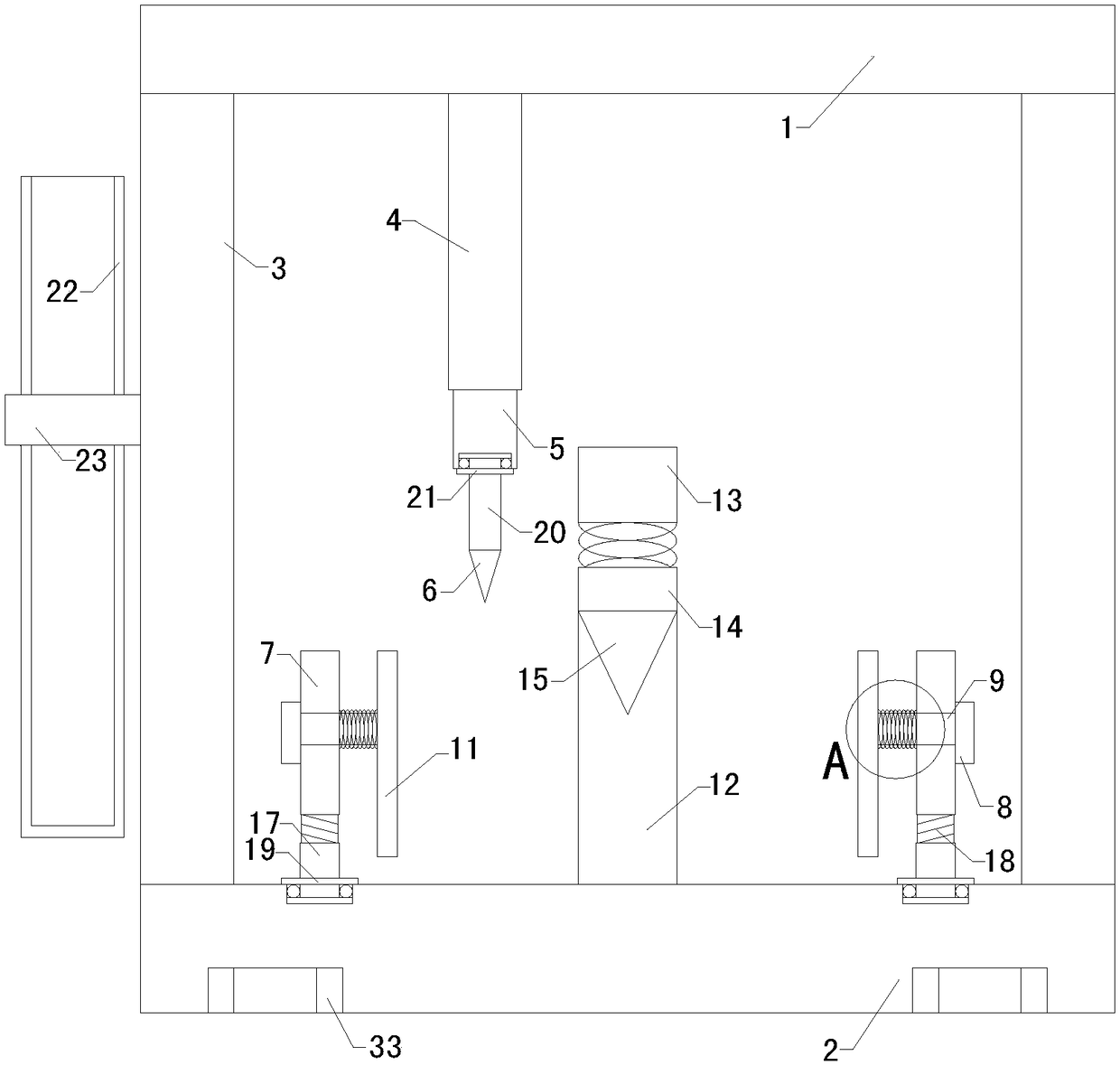

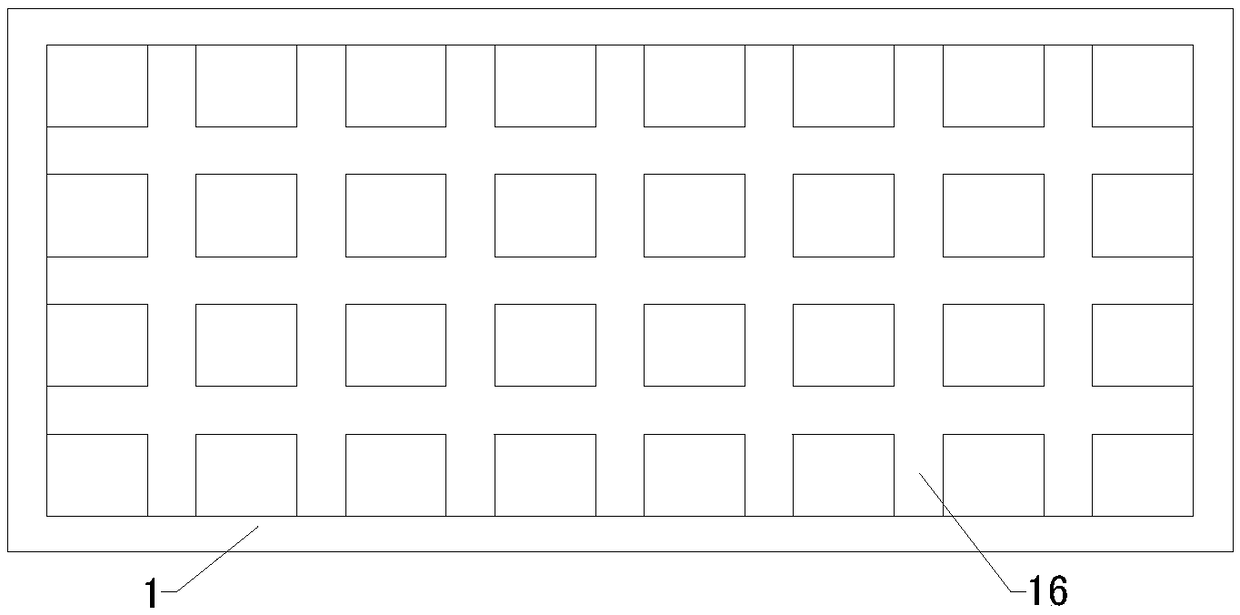

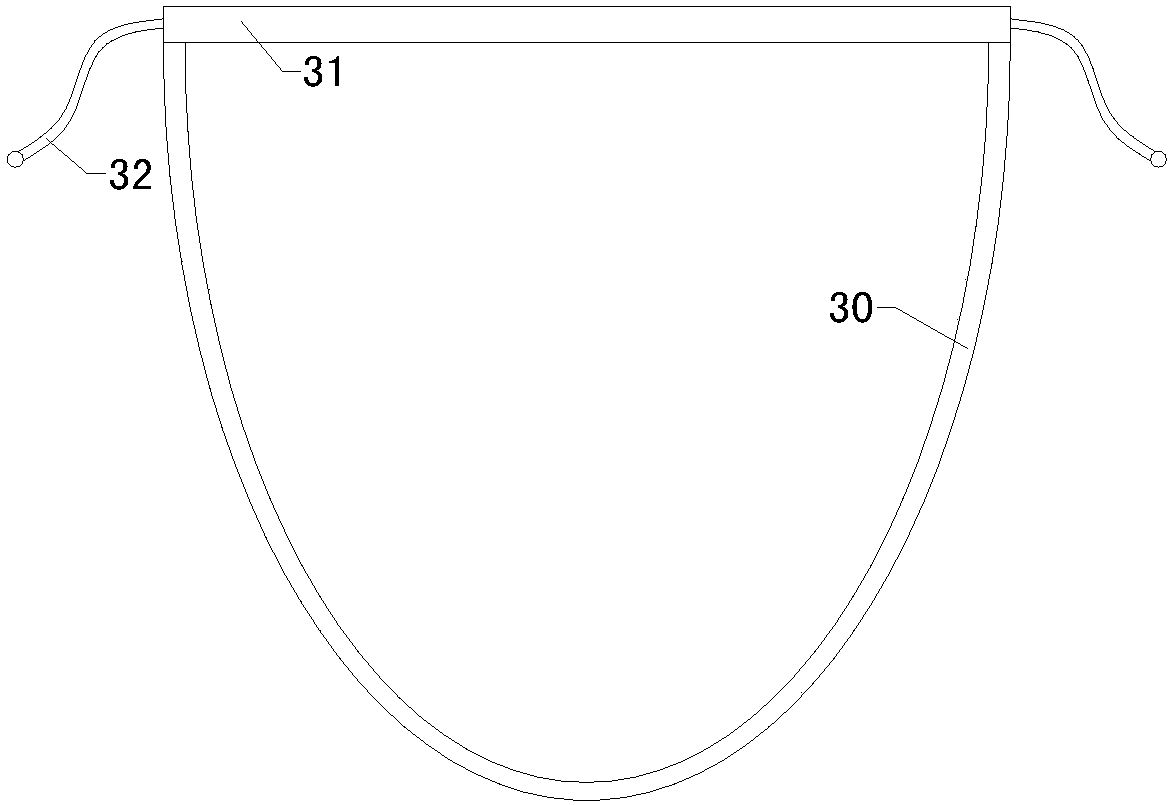

[0020] Such as Figure 1 to Figure 5 As shown, a kind of liquid crystal display module processing and production of the present invention assists display screen laminating equipment, comprises top board 1, bottom board 2, two groups of side boards 3, cylinder 4, expansion rod 5 and slice 6, two groups of side boards The top is respectively connected to the left and right sides of the bottom of the top plate, the bottom of the two sets of side plates is connected to the top of the bottom plate, and the top of the telescopic rod is installed at the output end of the bottom of the cylinder; it also includes two sets of fixing plates 7, two sets of pull plates 8, two sets of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com