Low temperature test box

A low-temperature test and box technology, applied to radio wave measurement systems, instruments, etc., can solve the problems of difficult to ensure the airtightness of the cable interface on the side wall, the low cooling phase rate of the test box, and the difficulty in meeting the production tasks, etc., to achieve a compact structure , Save labor assembly costs, test the effect of strong anti-interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

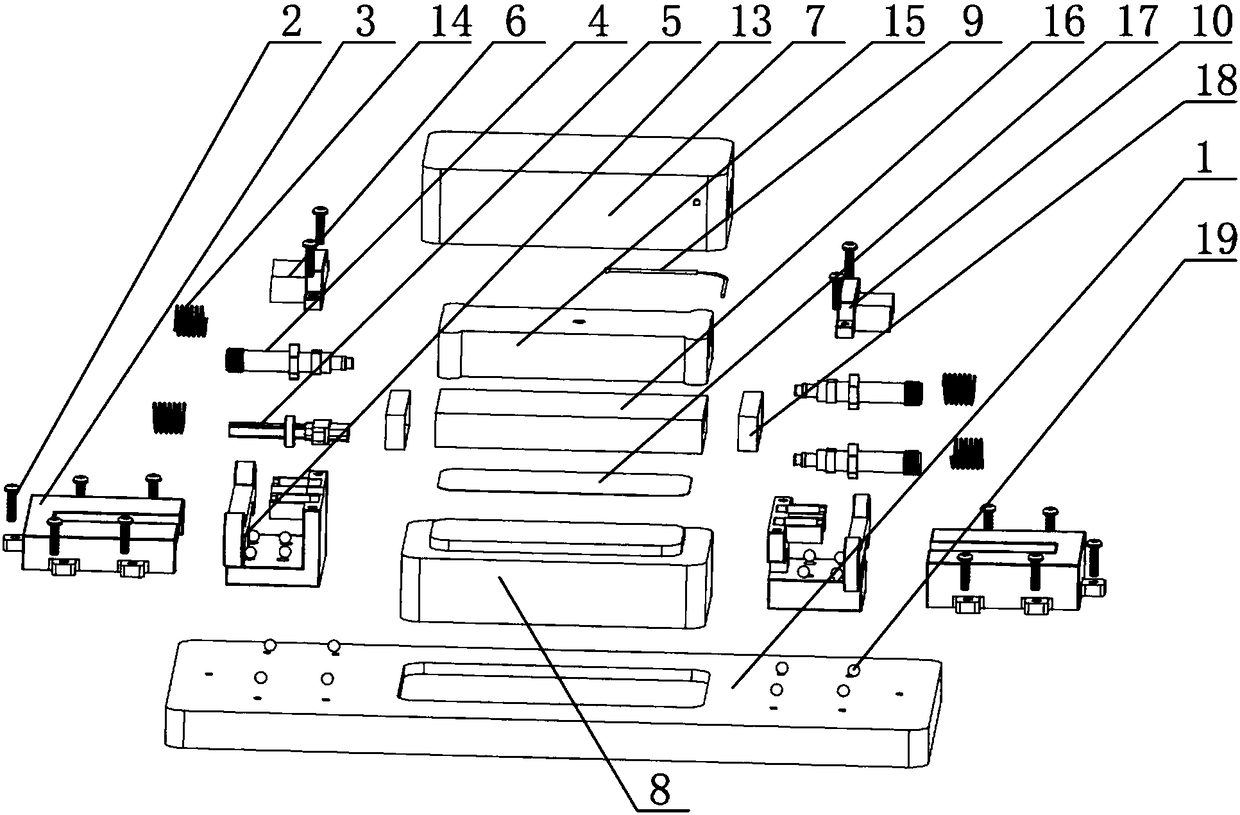

[0022] like figure 1 and figure 2 As shown, the low temperature test box of this embodiment includes a bottom plate 1, and the two ends of the bottom plate 1 are respectively symmetrically installed with assembly port slide rails 3 and antenna port slide rails 11 through balls 19, and assembly port slide rails 3 are installed with assembly port slide rails. block 13, the antenna port slide 12 is installed on the antenna port slide rail 11, the assembly port slide 13 and the antenna port slide 12 are relatively symmetrically arranged, and have the same structure; the collection port slide 13 and the antenna port slide 12 are all installed There are SMP connectors 4 and rectangular connectors 5 arranged in parallel intervals, the top of the two connectors located at the assembly port slider 13 is installed with the collection port pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com