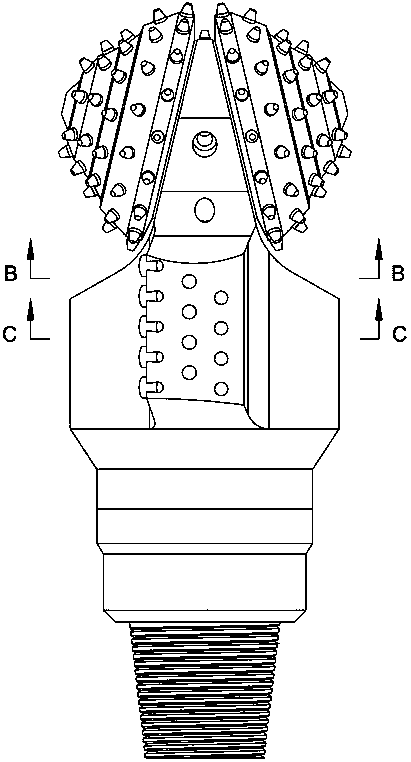

Split type drill bit with torsion impact function

A split-type, drill bit technology, which is applied in the direction of drill bits, drilling equipment, earthwork drilling and mining, etc., can solve the problems of low scraping efficiency and the impact of drill bit rock breaking efficiency, etc., and achieve the effect of tooth scraping efficiency improvement, good lubricating environment, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing.

[0028]Referring to the accompanying drawings, the split drill bit with torsional impact function is characterized in that: the split drill bit with torsional impact function is mainly composed of a drill body 4, a drill body joint 3, a cone upper body 7, a cone lower body 9, and a vibration generator. It is characterized in that: the drill bit body 4 is provided with an oil guide hole a40, an oil injection hole 47, a mud channel a48, a mud channel b49, and a threaded hole 50, the top of the drill bit body 4 is equipped with teeth 8, and the middle part of the drill bit body There are gauge teeth 2 and PDC teeth 6, nozzles a1 and nozzles b5 are respectively installed at the outlets of mud passage a48 and mud passage b49; the upper body 7 of the cone is provided with a plug hole b39, and the upper body 7 of the cone is inlaid with Teeth 8; the lower cone body 9 is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com