Method for determining dynamic coefficient of cast-in-place pile frame type roadbed structure

A technology of bored piles and dynamic coefficients, applied in infrastructure engineering, roads, roads, etc., to achieve the effect of adapting to engineering needs, clear process, and convenient implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

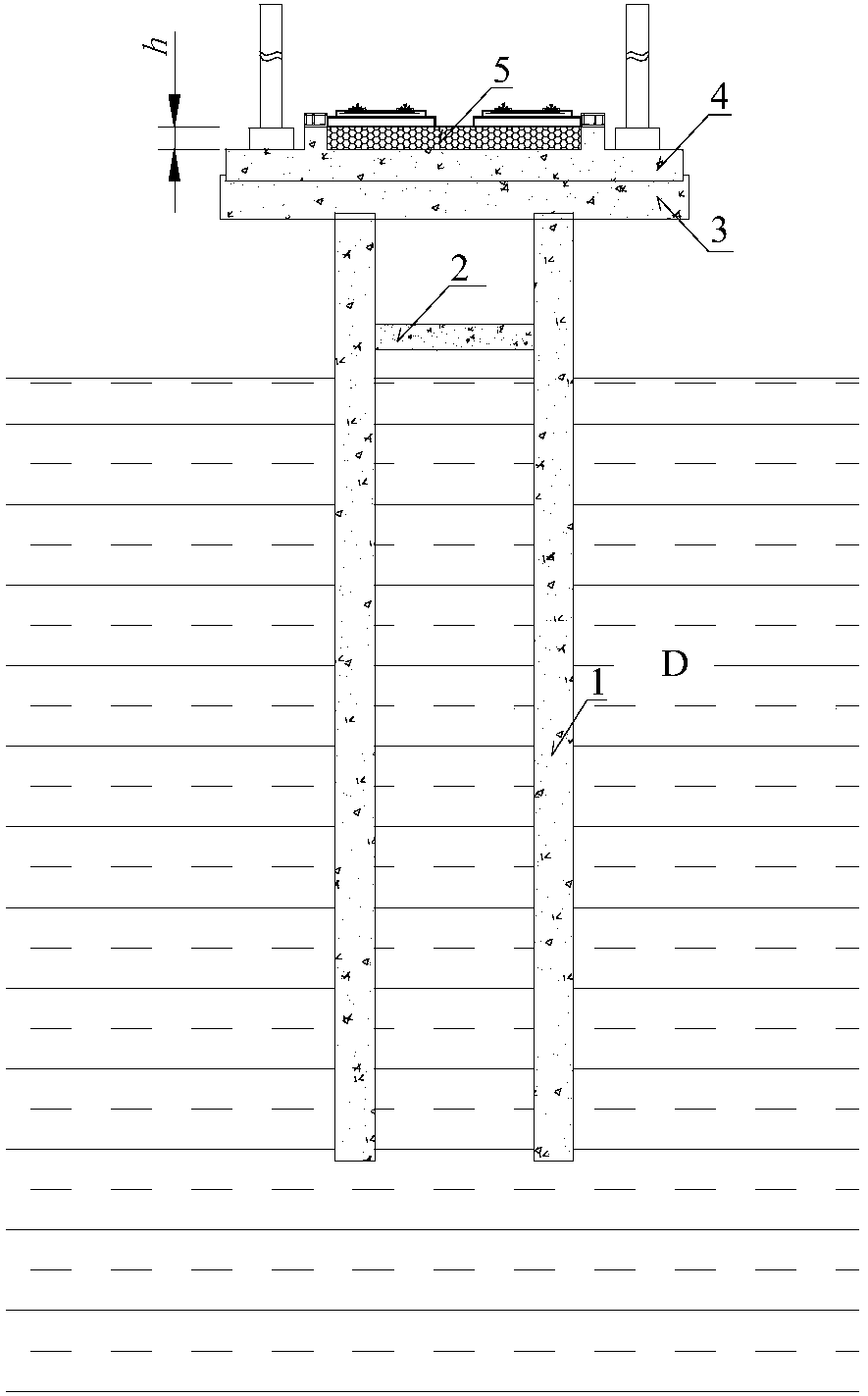

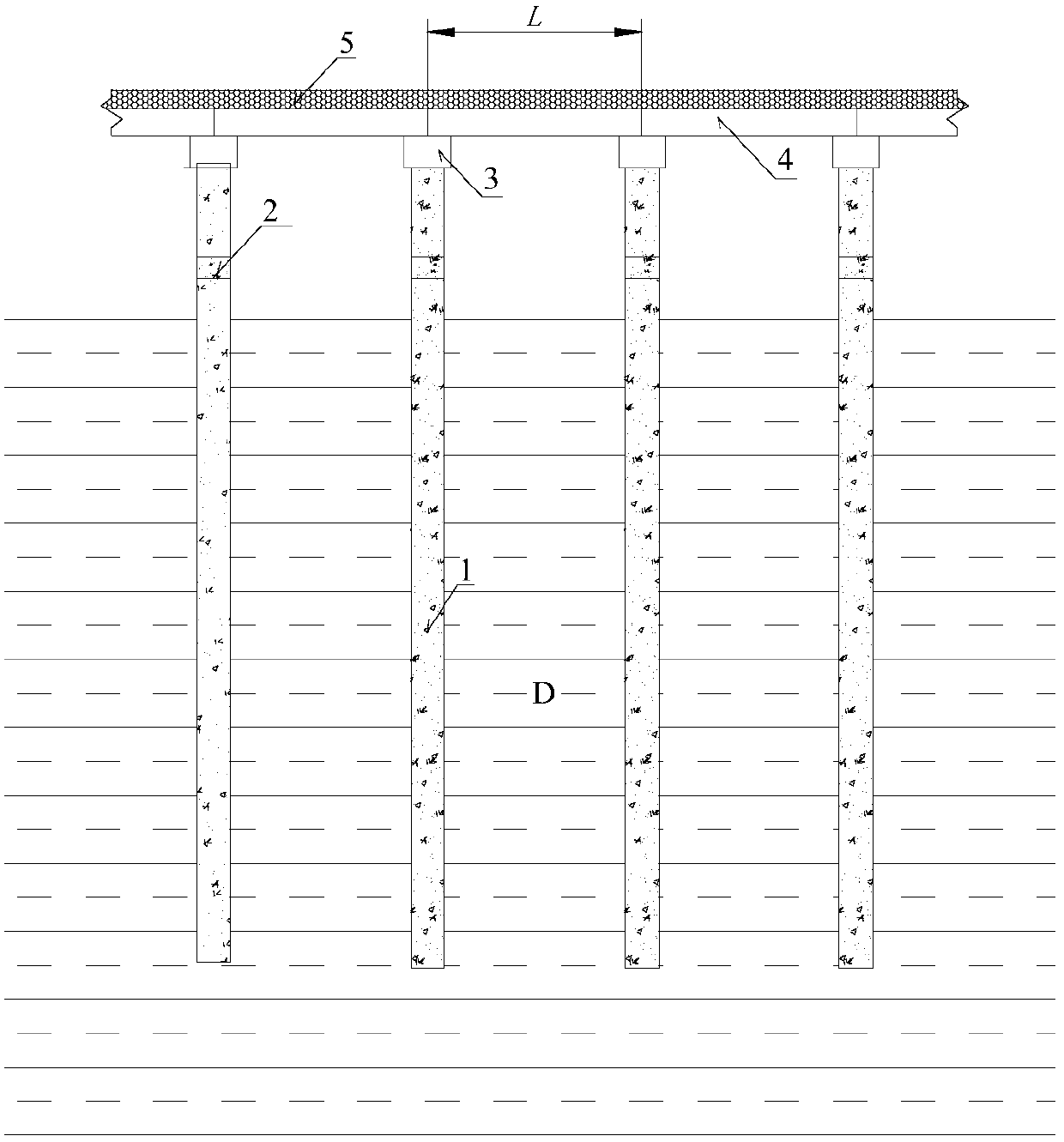

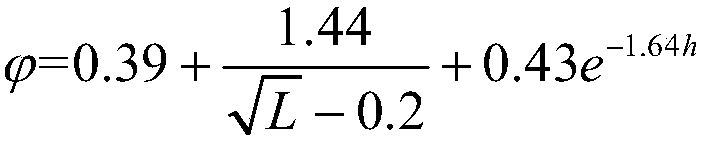

[0027] refer to figure 1 , figure 2 A plain high-speed railway uses a frame-type subgrade structure of bored piles to pass through soft soil areas. The pile diameter of the bored pile 1 in this structure is 1.5m, and the pile length of the bored pile 1 below the ground is 20m. The surface height of the foundation D is 4.5m; the cross-section width×height of the beam 2 is 1.25m×1.25m, and the length is 5m, which is set above the foundation D surface and connects two bored piles 1 in the direction of the cross section; the cross-section width of the joist 3× The height is 1.5m×1.2m, the length is 10.4m, and it is set on the top of bored pile 1; The building body 5 is constructed by graded crushed stone, and is set in the groove-shaped cavity of the groove-shaped span board 4, with a thickness of 0.4m.

[0028] Adopt the method of the present invention below to determine the dynamic coefficient of this bored pile frame type subgrade structure, concrete steps are as follows:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com