Paper cup collecting and piling system on cup handle paper cup shaping machine

A technology for forming machines and paper cups, applied in the field of paper cup collection and stacking systems, can solve the problems of wasting labor, low work efficiency, easy to fall, etc., and achieve the effects of facilitating conveying and stacking, improving work efficiency, and reducing labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

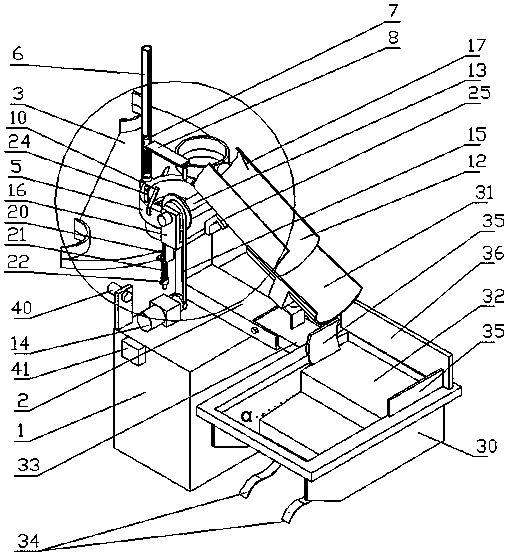

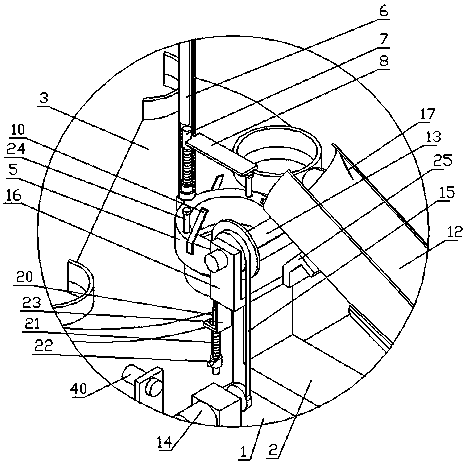

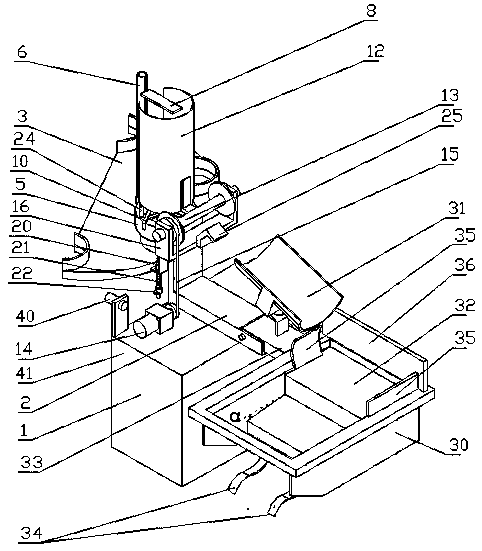

[0011] As shown in the drawings, the present invention includes a base 1, a paper cup collecting device, a batch unloading device and an automatic stacking device. The base 1 is provided with an L-shaped support frame 2, and the base 1 is located on the side of the discharge tray 3 of the paper cup forming machine. , the paper cup collection device includes a cylindrical cup holder 5, a guide cylinder 6, a guide rod 7 and a pressing plate 8, the cylindrical cup holder 5 is installed on one end of the L-shaped support frame 2, and is located above the discharge tray 3 of the paper cup forming machine There are a plurality of first elastic stoppers 10 in an annular array on the top of the cylindrical cup holder 5, and the movable ends of the plurality of first elastic stoppers 10 are respectively inclined to the center of the cylindrical cup holder 5, and the cylindrical cup holder The top of the frame 5 is provided with a guide cylinder 6 connecting the screw rod, and one end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com