Safety socket

A technology of safety sockets and socket holes, which is applied in the direction of two-part connection devices, contact parts, electrical components, etc., can solve the problems of cumbersome installation and production, short service life, easy damage, etc., and achieve the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

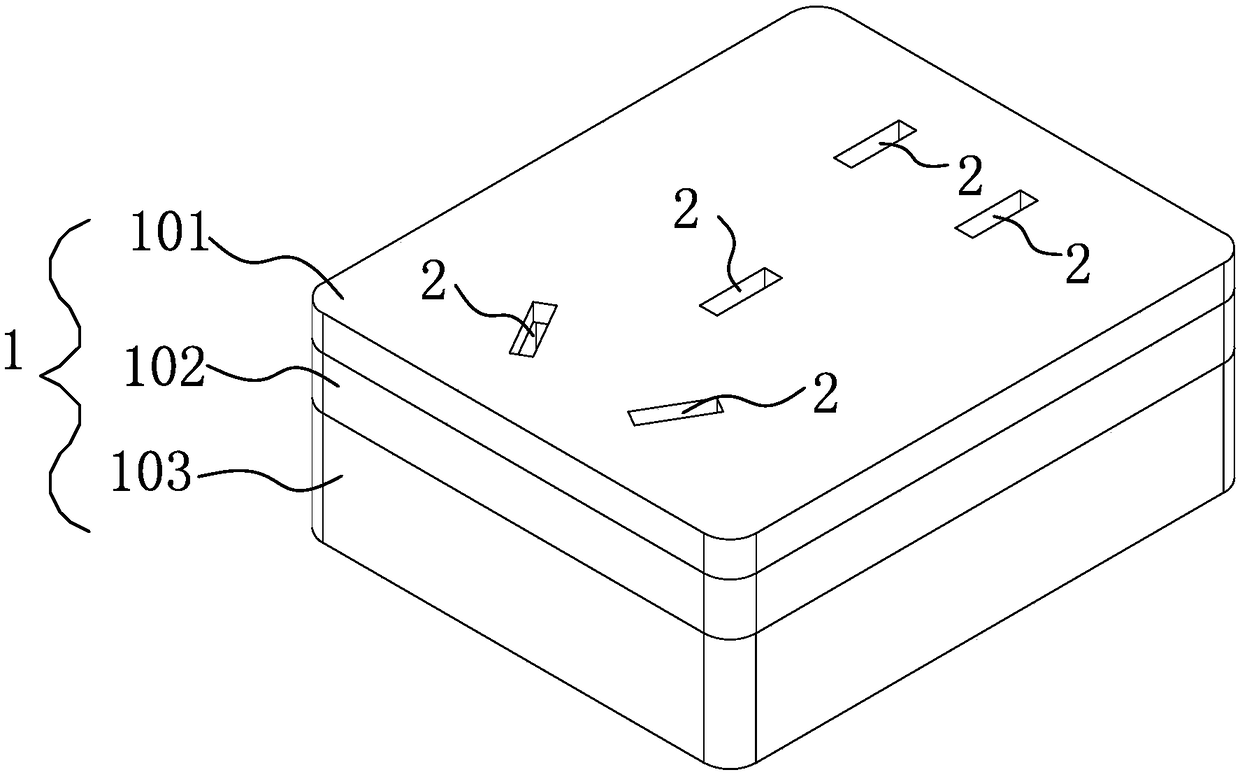

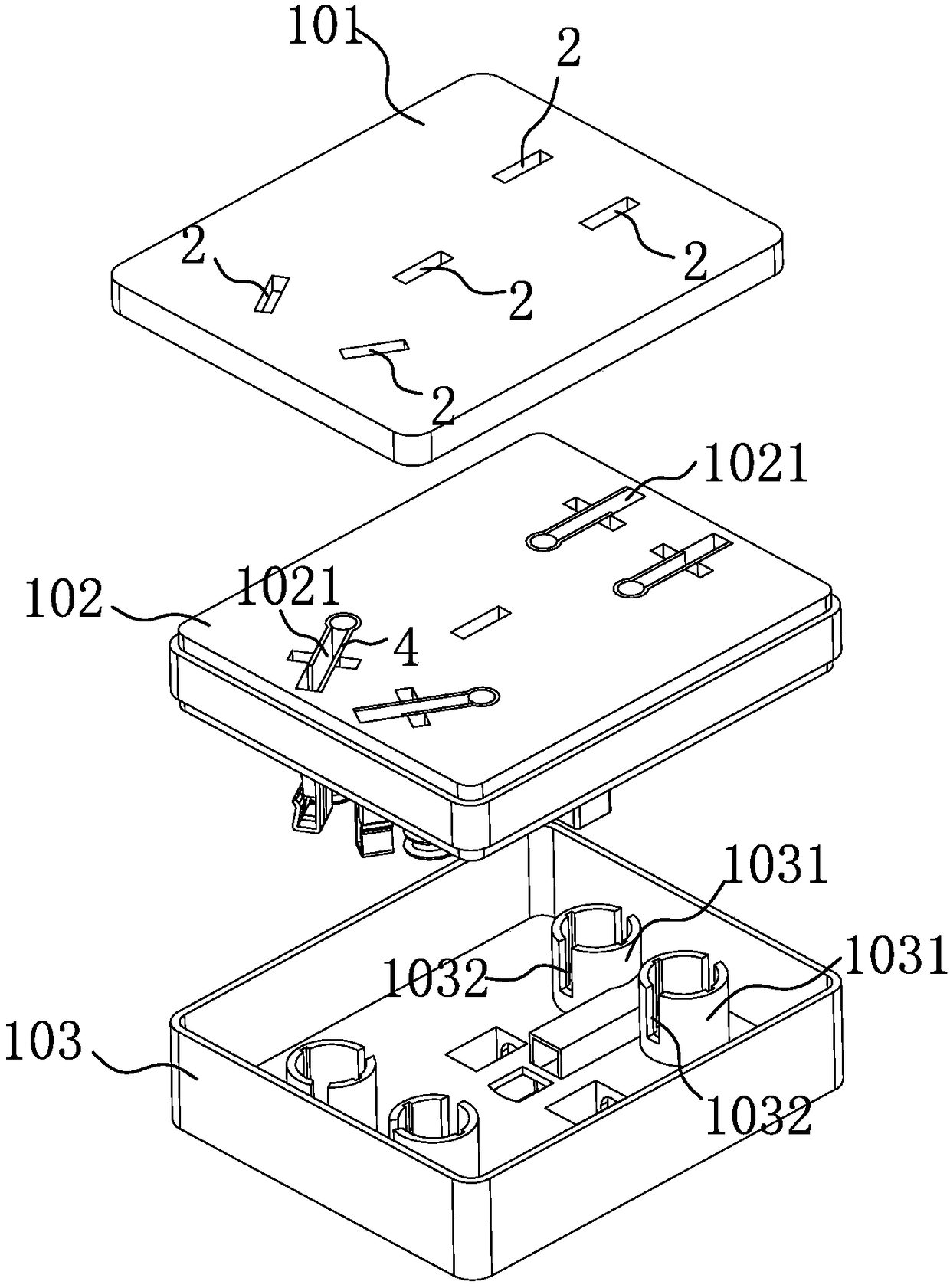

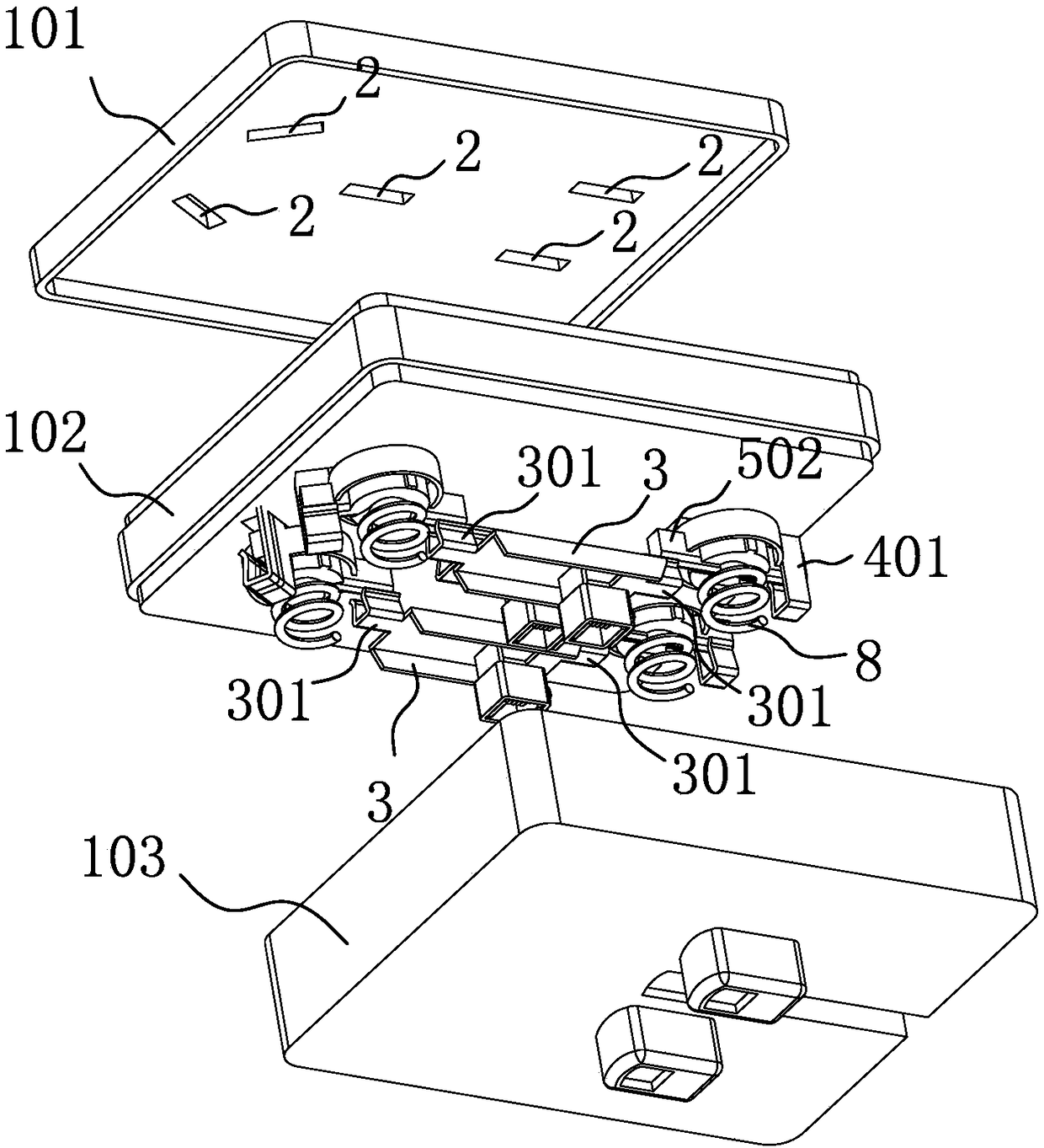

[0019] Such as Figure 1-3 As shown, the safety socket includes a housing 1 and a plurality of sets of conductive contact pieces 3 arranged in the housing 1 to match the pole pieces of the plug, power supply terminals, and a transition mechanism with the same number as the number of jacks of the socket. The contact piece 3 is electrically connected to the power terminal, and the housing 1 is provided with a corresponding number of socket holes 2 . If it is a three-plug socket, three groups of conductive contact pieces 3 and three transition mechanisms are provided, and three socket holes 2 are provided on the housing 1 . This specific embodiment is a three-insert plus two-insert socket, so five groups of conductive contact pieces 3 and five transition mechanisms are arranged in total. Five socket holes 2 are arranged on the housing 1, and each socket hole 2 corresponds to a conductive contact piece 3 and A transition mechanism can also omit the conductive contact piece 3 corr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com