safety socket

A safety socket and socket hole technology, applied in electrical components, devices to prevent contact with live contacts, coupling devices, etc., can solve the problems of hidden dangers of sockets, casualties and other problems, and achieve the effect of avoiding electric shocks for children

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

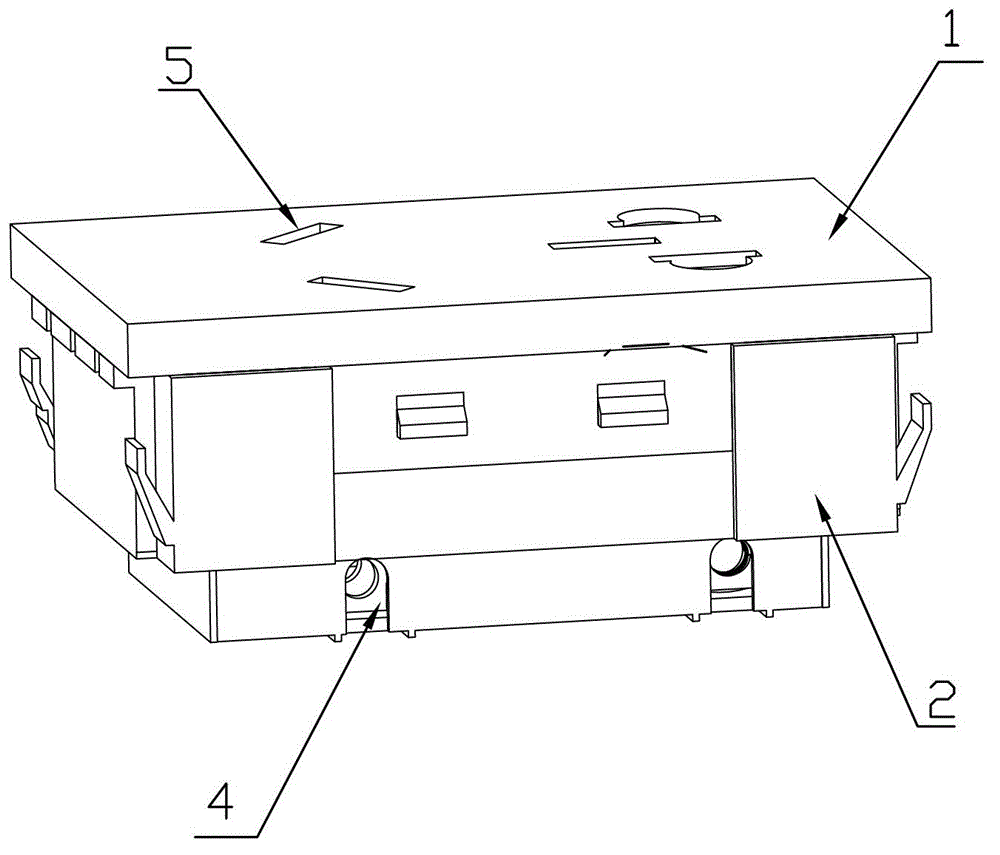

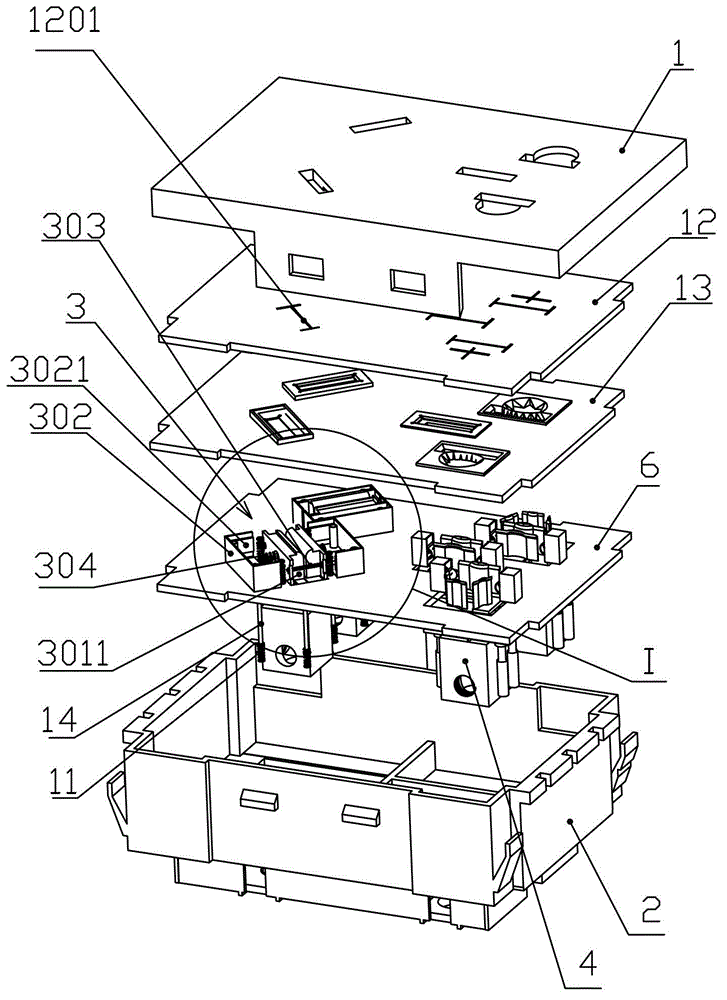

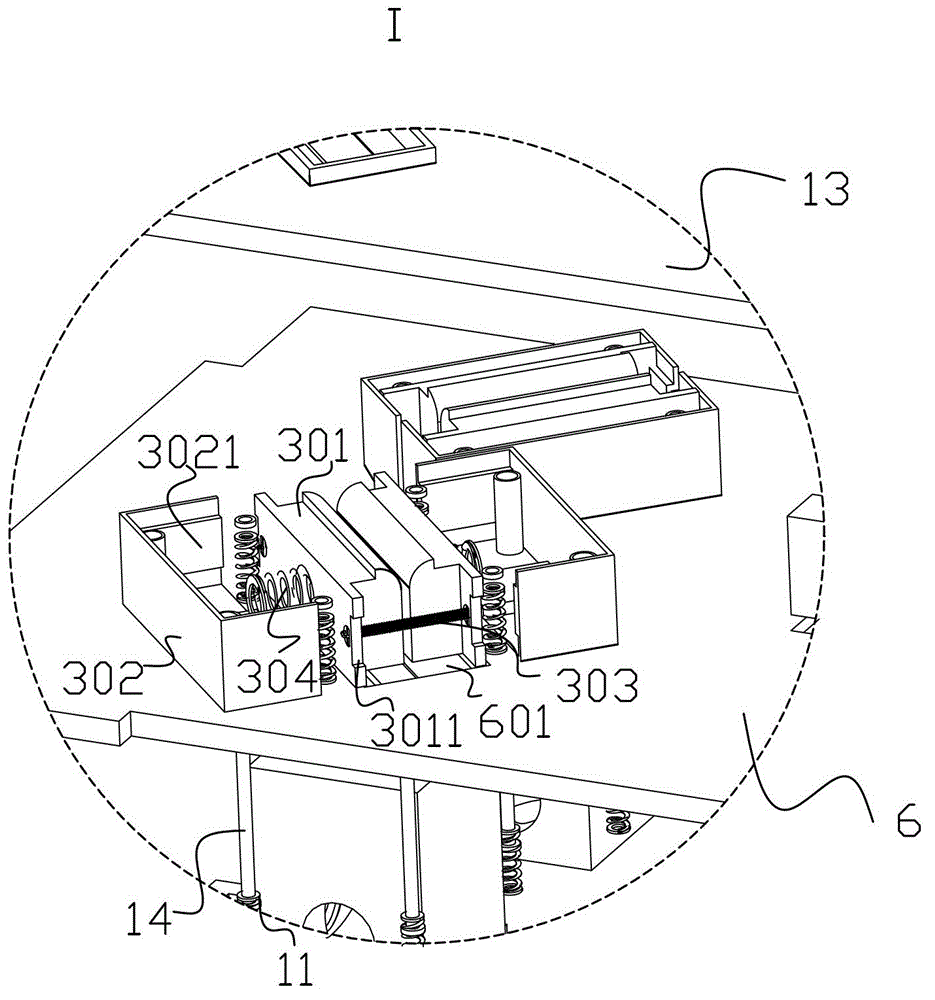

[0013] like Figure 1-3 As shown in the figure, the safety socket includes a casing and a plurality of groups of conductive contact pieces and power supply terminals 4 arranged in the casing to match the plug pole pieces. The casing includes an upper cover 1 and a base 2, and the socket hole 5 is arranged in the On the upper cover 1, the clamping assembly 3 is arranged at a position corresponding to the lower part of the socket hole 5, a clamping member mounting plate 6 is fixed in the housing, and the multiple groups of clamping assemblies 3 are arranged in the clamping on the mounting plate 6. For the flat clamping assemblies 3, each set of the clamping assemblies 3 includes a pair of oppositely established metal clips 301 and a clip elastic clamping mechanism, the clip elastic clamping mechanism makes the oppositely established metal clips 301 has an elastic clamping force to prevent the inserted plug from being ejected by the force of the transition plate reset mechanism....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com