Direct-current leakage current test device

A DC leakage and current testing technology, applied in the direction of measuring devices, measuring current/voltage, measuring electrical variables, etc., can solve the influence of the operator's boosting and reading measurement data, different DC leakage current values, and inconvenient pressure and reading and other problems, to achieve the effect of reducing life damage, improving test efficiency, efficient and reliable transmission and reading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

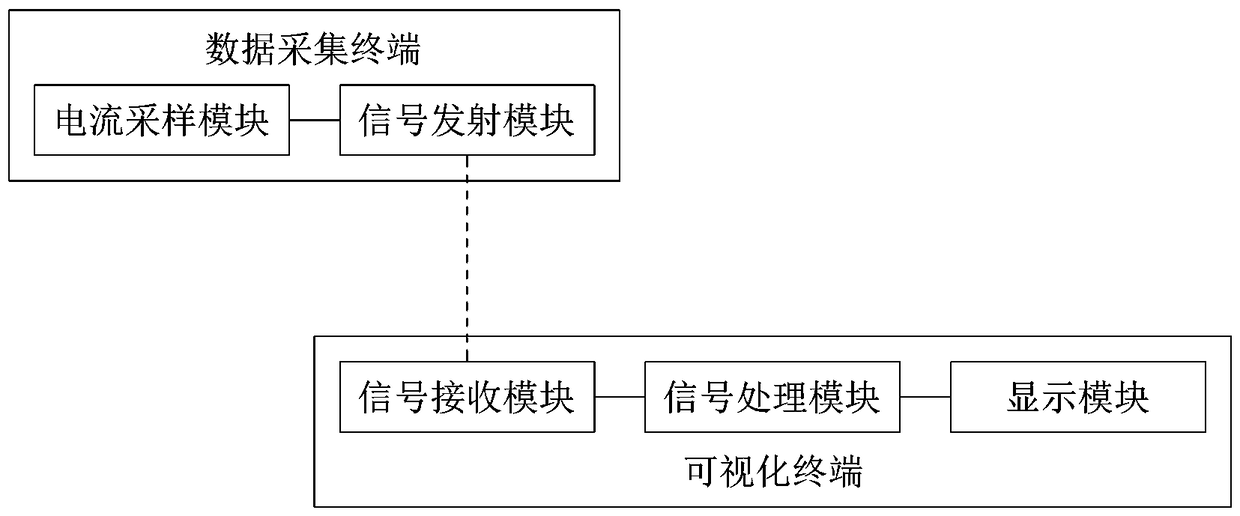

[0023] Embodiment one: as attached figure 1 As shown, a DC leakage current testing device for testing the DC leakage current of an insulation test object includes a data acquisition terminal and a visualization terminal that are separately set up and capable of remote communication.

[0024] The data acquisition terminal is connected with the insulation test object under test, and it is used for sampling the DC leakage current of the insulation test object and sending out a remote signal containing the information of the DC leakage current. The visualization terminal communicates remotely with the data acquisition terminal and is used to receive and analyze the remote signal to display the DC leakage current information.

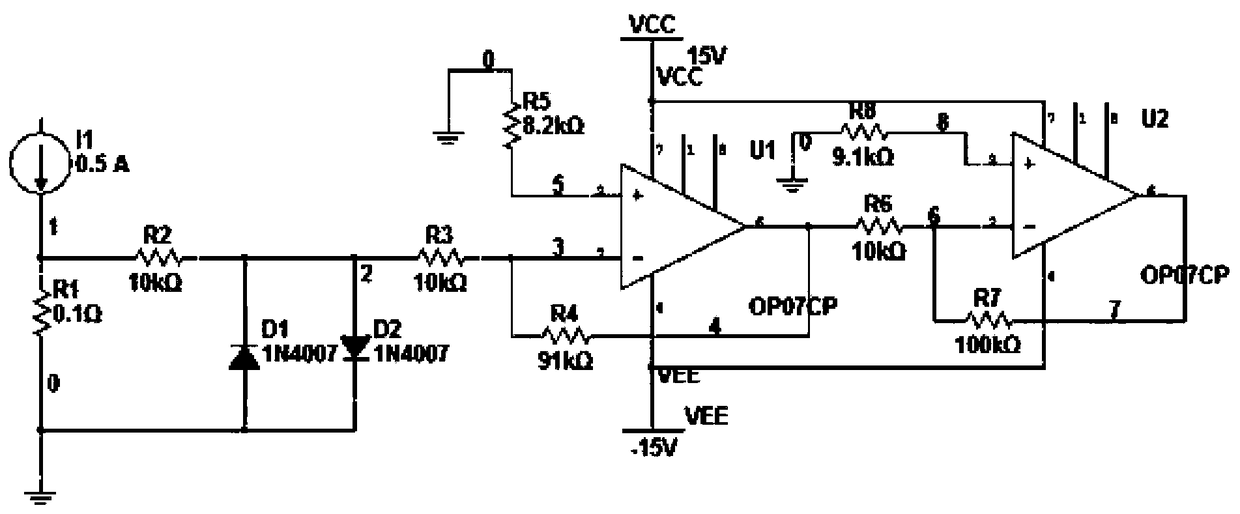

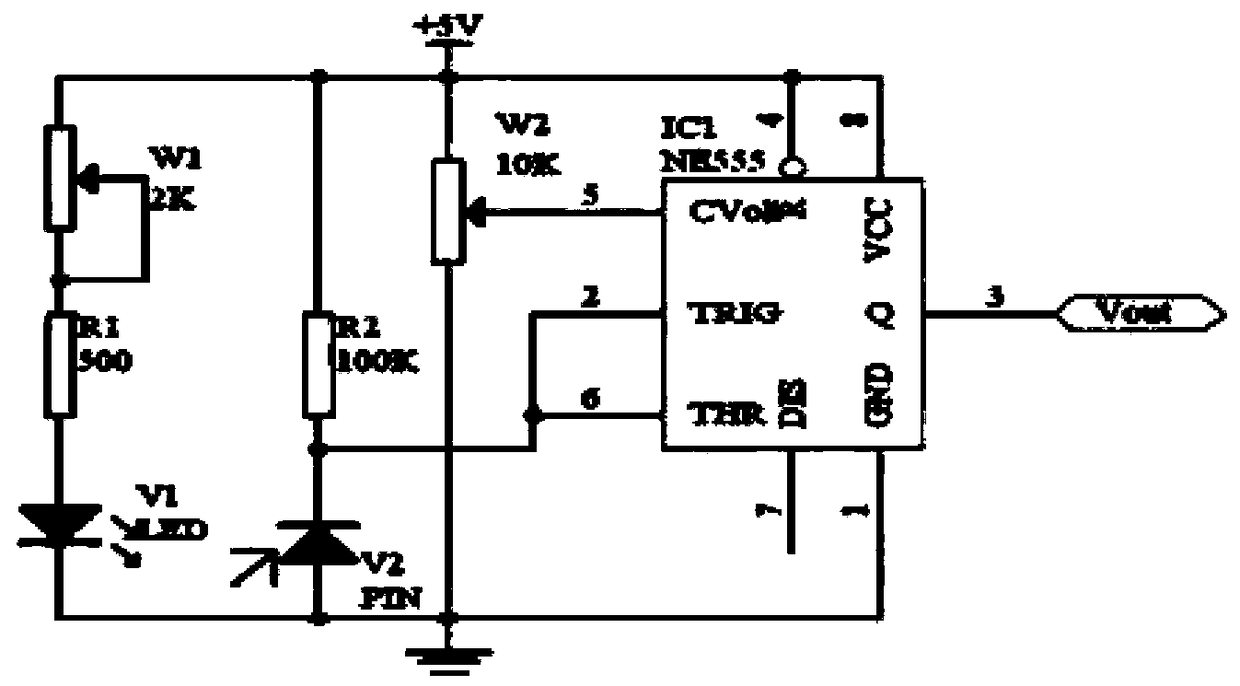

[0025] The data acquisition terminal includes a current sampling module for sampling the DC leakage current of the insulation test object, and a signal transmitting module connected with the current sampling module and transmitting a remote signal. The visu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com