Design method of a comprehensive environmental test chamber for civil aircraft braking system

A technology of integrated environment and braking system, applied in the field of development of civil aircraft braking system environmental test equipment, can solve problems such as unguaranteed testing, achieve the effects of improving development quality, improving social benefits, and avoiding maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The specific embodiments of the present invention will be further described below with reference to the accompanying drawings.

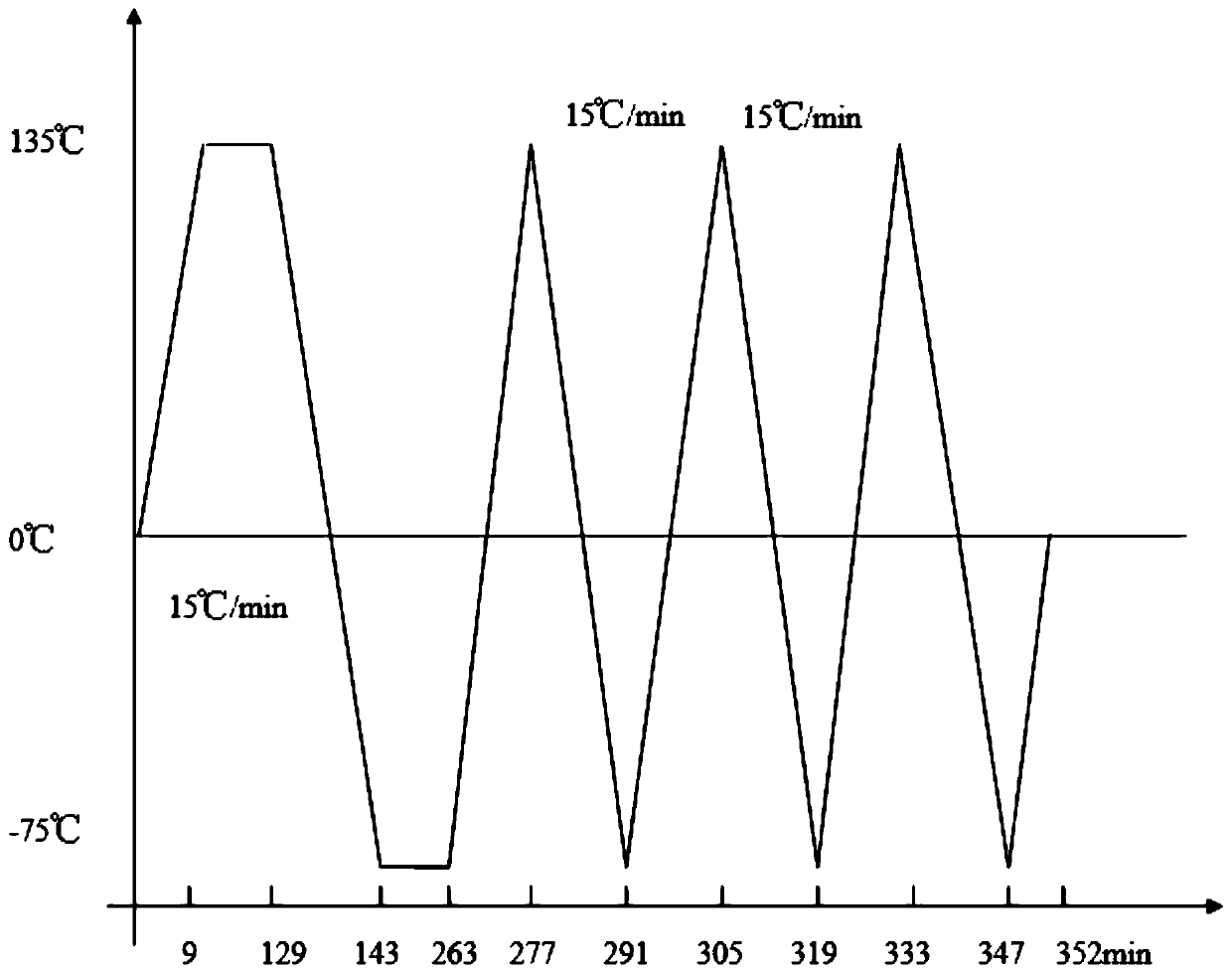

[0043] This embodiment determines the design parameters of a comprehensive environmental test box for a civil aircraft brake system. The comprehensive environmental test box can be combined with an electric vibrating table, high temperature and low temperature oil sources to perform high temperature life test, low temperature life test, Comprehensive stress test. The design parameters of the test chamber include:

[0044] High temperature range; low temperature range; heating and cooling rates under load conditions; temperature protection design for the brake system; structural design. In order to meet the test requirements of the braking system, the mean time between failures MTBF of the comprehensive environmental test box is 5000h.

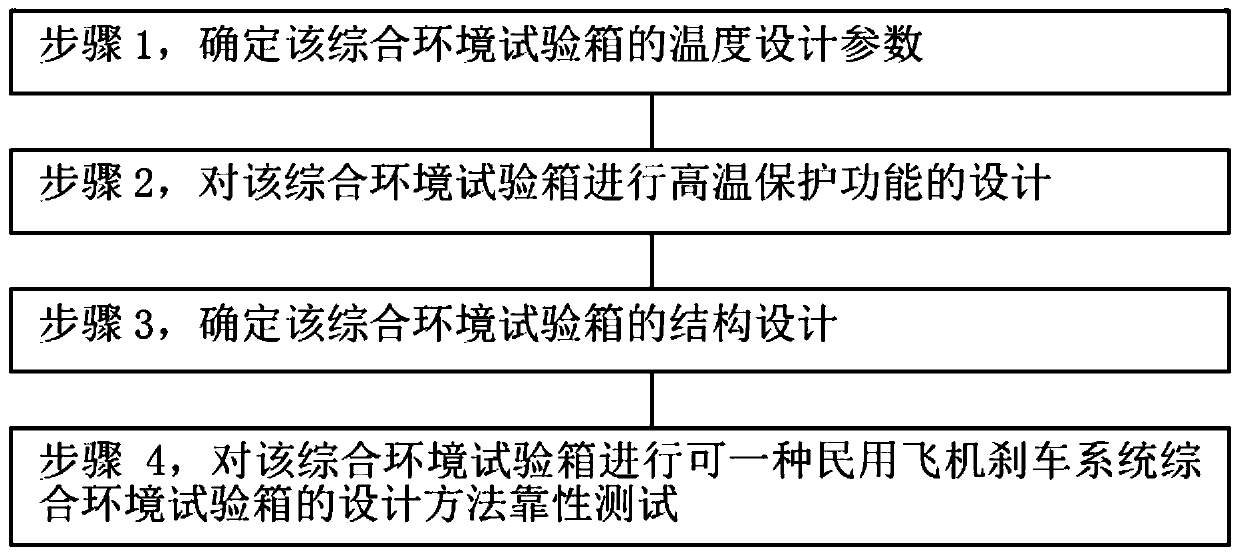

[0045] see figure 2 , the specific process of this embodiment is:

[0046] Step 1: Determine the temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com