Tin melting furnace for producing tin ingots

A technology for melting tin and tin ingots, applied in the field of tin ingot production equipment, can solve the problems of insufficient heating of tin melting furnaces, failure to meet requirements, high energy consumption, etc., and achieve the effects of improving melting effect, simple structure, and improving stirring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

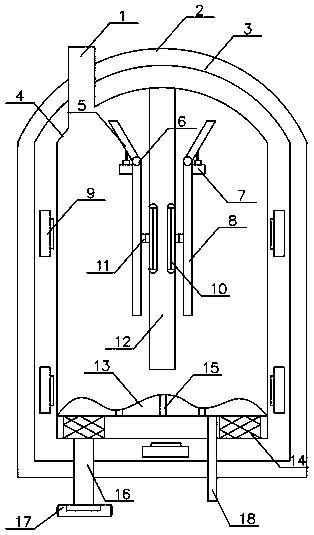

[0019] Such as figure 1 As shown, a tin melting furnace for producing tin ingots according to the present invention includes a feed inlet 1, an insulating layer 2, a furnace body 3, an inner lining 4, a movable plate 5, a rotating shaft 6, a pusher 7, and a push plate 8 , electric heater 9, hydraulic pump 10, hydraulic rod 11, pole 12, floating plate 13, spring 14, leakage hole 15, ventilation pipe 16, air pump 17, discharge port 18, lining 4 is set in furnace body 3 , an electric heater 9 is set between the inner lining 4 and the furnace body 3, the electric heater 9 is connected to an external power supply through a wire, a feed port 1 and a discharge port 18 are set on the furnace body 3, and the inner liner 4 is set Strut 12, a hydraulic pump 10 is arranged in the support rod 12, and a push plate 8 is arranged outside the support rod 12. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com