Large denoising gear convenient to splice and demount

A large-scale, noise-reducing technology, applied in the field of hardware, can solve problems such as high cost of use, inconvenient maintenance, and increased noise, and achieve the effects of reducing vibration, reducing noise, and reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

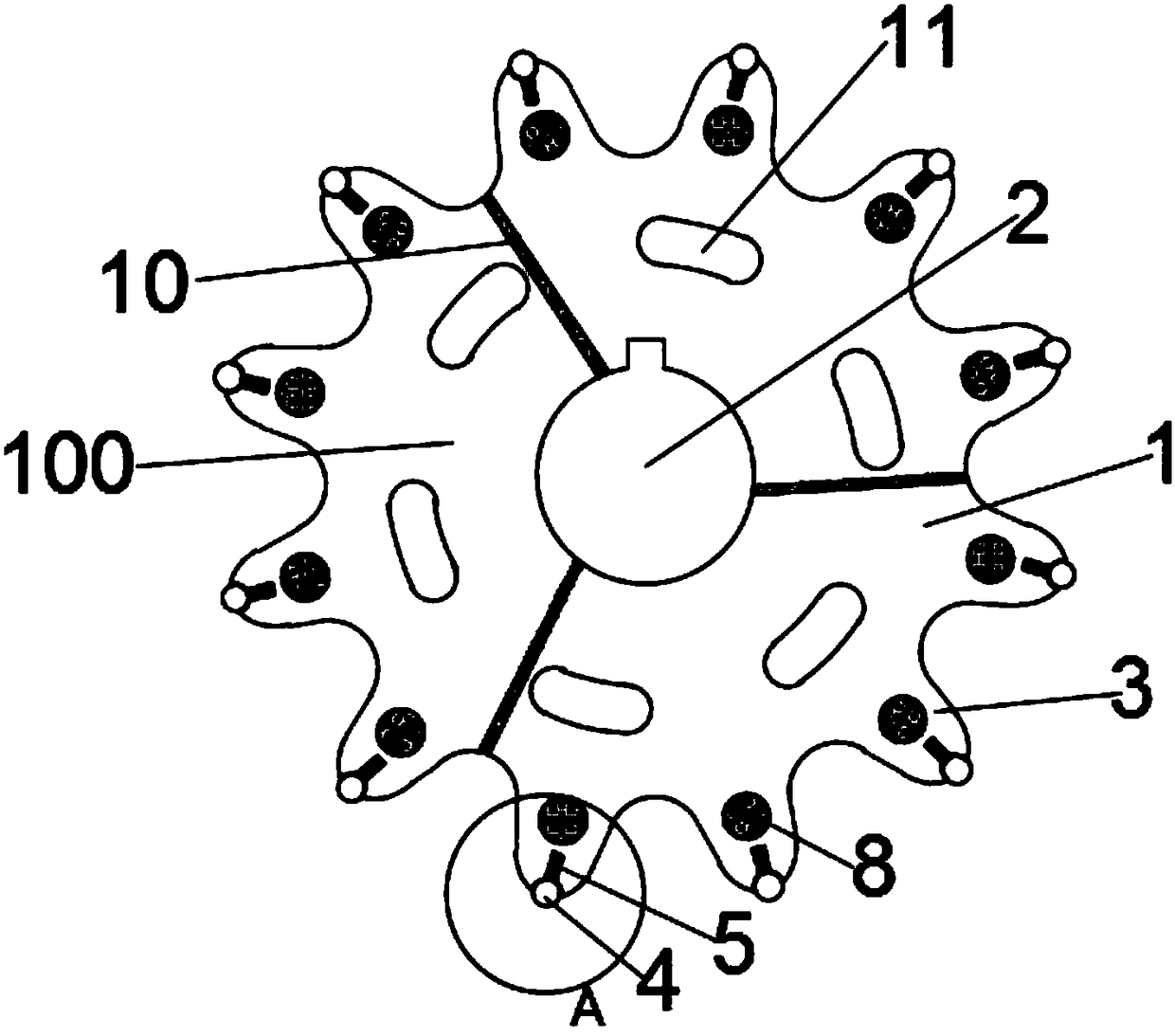

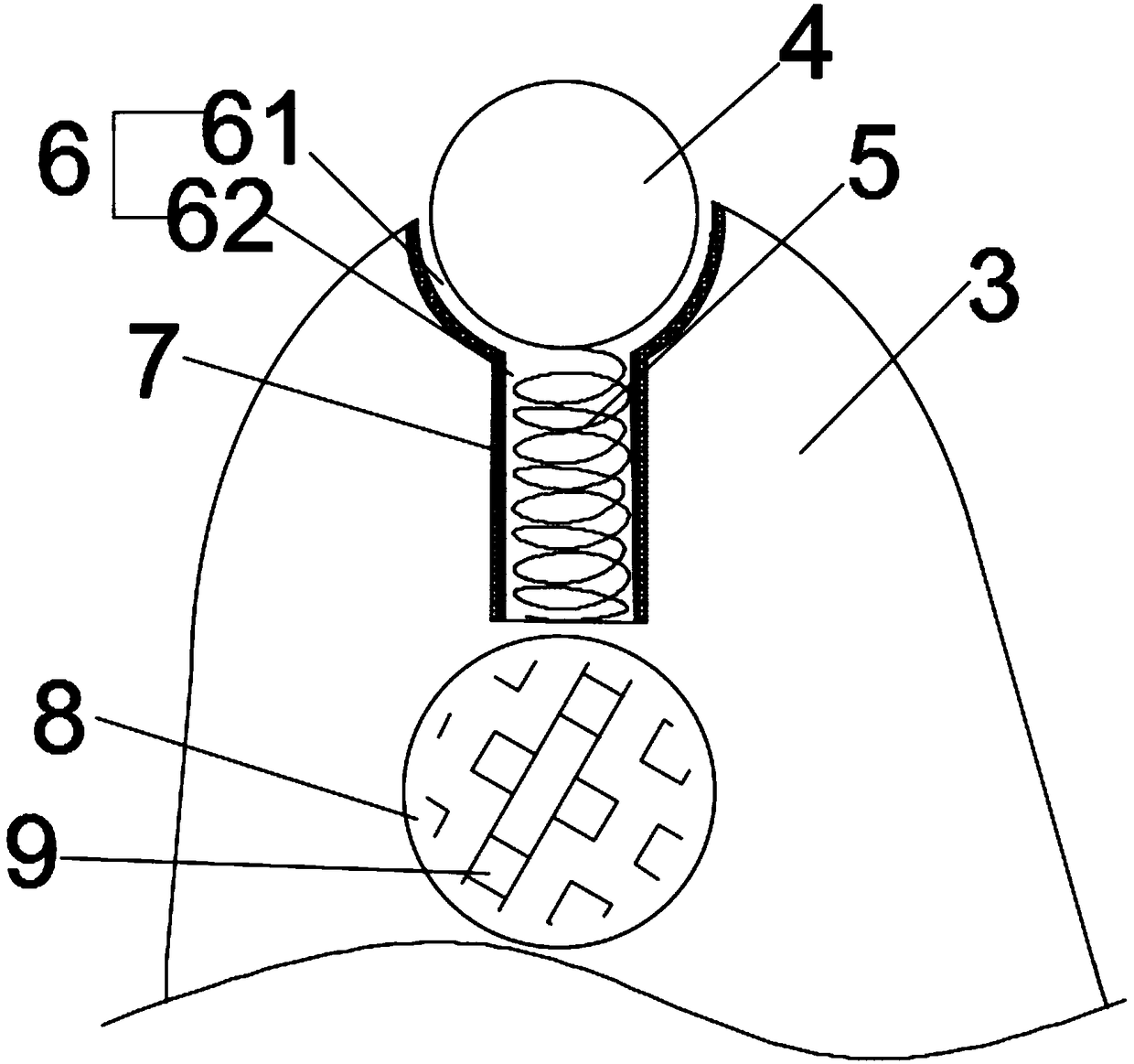

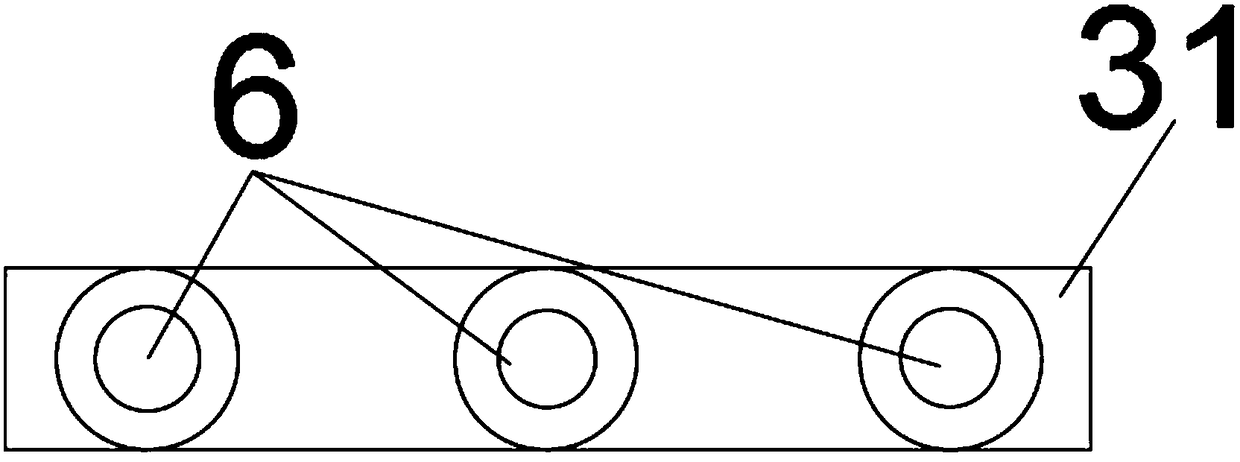

[0022] A large-scale noise reduction gear that is convenient for splicing and disassembly of the present invention, such as Figure 1-5 As shown, it includes a gear body 1, and the gear body 1 is spliced by three gear units 100 through a connecting plate 10; the connecting plate 10 includes a connecting plate body 101 and a connecting boss 102, and the connecting plate body 101 is Conical structure, the connecting boss 102 is located on both sides of the connecting plate body 101 and the connecting plate 10 is connected and fixed to the side surfaces of two adjacent gear bodies 1 through the connecting boss 101 provided on the side of the connecting plate body 101 , the side of the gear body 1 is provided with a connection slot (not shown) that matches the connecting boss 101; the outer peripheral edge of the gear body 1 is provided with a number of teeth 3, and the center position of the gear body 1 is There is a shaft hole 2; the gear body 1 is provided with a sound-absorb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com