High-performance vegetation pervious concrete

A permeable concrete, high-performance technology, used in applications, home appliances, ceramic products, etc., can solve problems such as hindering the popularization and application of plant permeable concrete, poor plant adaptation, and poor durability, and achieve high connected porosity and water permeability. Pore alkalinity, the effect of ensuring strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

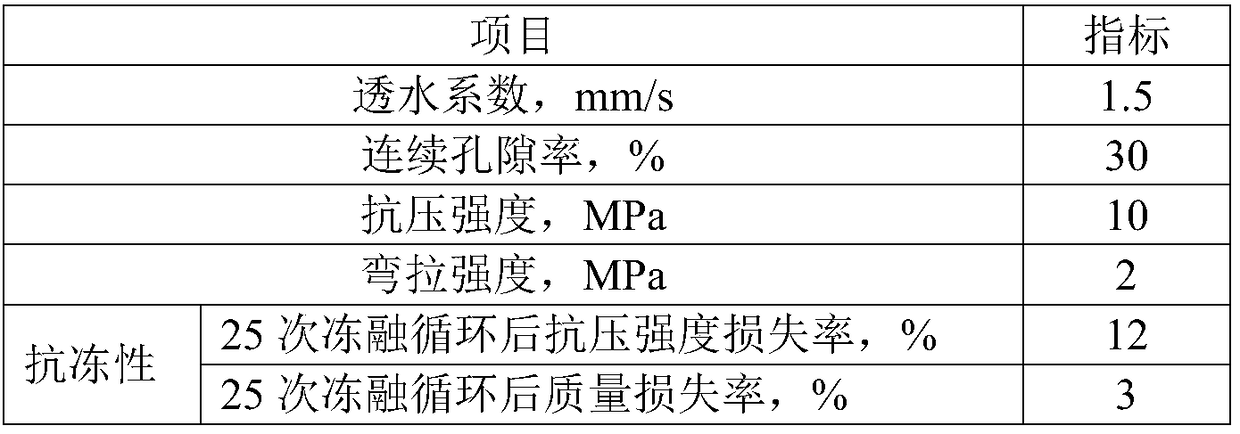

Embodiment 1

[0028] The high-performance plant-growing permeable concrete provided in this embodiment includes the following components in proportion by mass: Ordinary Portland Cement 5, Low-alkalinity Sulfur-Alumino-Silicate Cement 5, Gypsum 5, Slag 3, Fly Ash 3, Silica fume 3, aggregate 80, water reducer 0.3, early strength agent 0.1, redispersible latex powder 0.1, thickener 0.01, fiber 0.1, water 4.

[0029] The preparation method of the high-performance vegetable permeable concrete is as follows:

[0030] (1) First add all aggregates and water accounting for 30-40% of the total mass of water to the mixer, and stir for 30-60 seconds to pre-wet the aggregates and reach a saturated surface-dry state;

[0031] (2) Then add cementing material accounting for 40-60% of the total mass of cementing material (cementing material refers to other raw materials except aggregate, water reducing agent and water), and stir for 30-60 seconds to make the surface of the aggregate evenly covered with a sl...

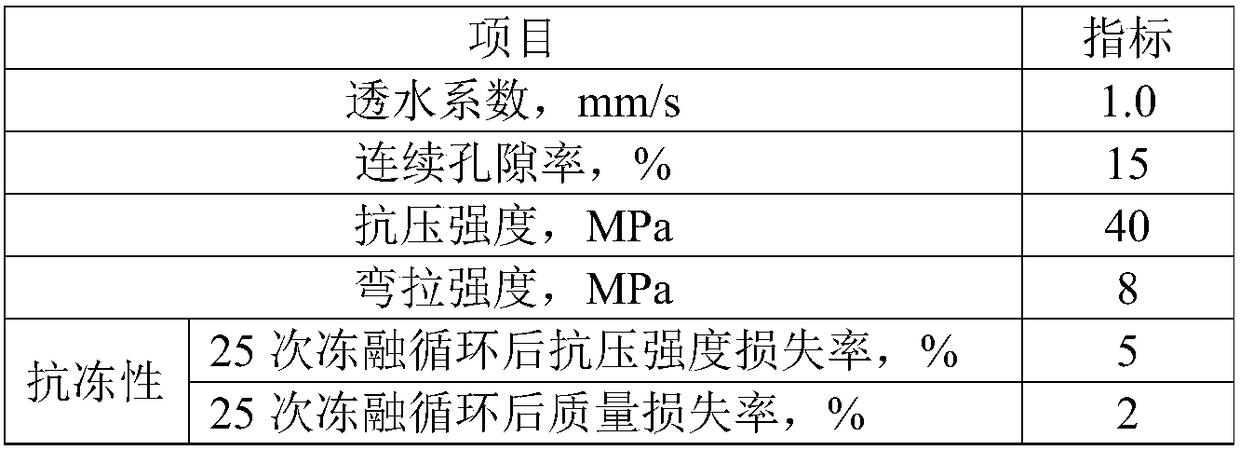

Embodiment 2

[0038] The high-performance plant-growing permeable concrete provided in this embodiment includes the following components in proportion by mass: ordinary Portland cement 10, low-alkalinity sulfoalumino-silicate cement 10, gypsum 10, slag 5, fly ash 5, Silica fume 5, aggregate 60, water reducer 0.7, early strength agent 0.5, redispersible latex powder 1.0, thickener 0.1, fiber 1.0, water 10.

[0039] The preparation method of the high-performance plant-growing permeable concrete is the same as that in Example 1.

[0040] The performance indicators of the high-performance plant-grown permeable concrete are shown in Table 2 below.

[0041] Table 2 The performance index of the high-performance plant-growing permeable concrete of this embodiment

[0042]

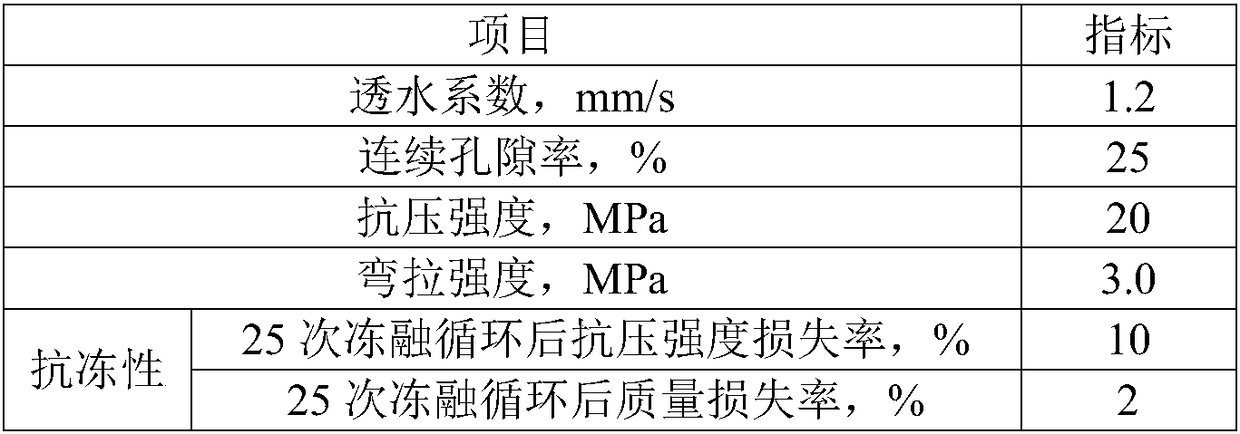

Embodiment 3

[0044] The high-performance plant-growing permeable concrete provided in this embodiment includes the following components by mass ratio: ordinary Portland cement 8, low-alkalinity sulfoaluminum silicate cement 7, gypsum 7, slag 4, fly ash 4, Silica fume 4, aggregate 70, water reducer 0.3, early strength agent 0.2, redispersible latex powder 0.5, thickener 0.05, fiber 0.15, water 7.

[0045] The preparation method of the high-performance plant-growing permeable concrete is the same as that in Example 1.

[0046] The performance indicators of the high-performance plant-grown permeable concrete are shown in Table 3 below.

[0047]Table 3 The performance index of the high-performance plant-growing permeable concrete of this embodiment

[0048]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com