Preparation technology of zirconium tetrachloride and zirconium dioxide

A technology of zirconium tetrachloride and preparation process, applied in zirconium oxide, zirconium halide and other directions, can solve the problems of low automation level, low efficiency, large waste acid discharge and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The present embodiment provides a kind of preparation technology of zirconium tetrachloride, comprises the following steps:

[0037] 1) Add zircon sand, carbon reducing agent, and chlorine gas into the first-stage fluidized chlorination furnace, heat, and a first-order chlorination reaction occurs to generate zirconium tetrachloride, silicon tetrachloride, carbon monoxide, and carbon dioxide to obtain the first gas mixture ; The first gas mixture includes zirconium tetrachloride, silicon tetrachloride, carbon monoxide, carbon dioxide.

[0038] 2) Separate carbon monoxide from the first gas mixture, pass carbon monoxide into the secondary boiling chlorination furnace, add zircon sand and chlorine gas into the secondary boiling chlorination furnace, heat, and the secondary chlorination reaction occurs to form zirconium tetrachloride, silicon tetrachloride, and carbon dioxide to obtain a second gas mixture. The second gas mixture includes zirconium tetrachloride, silicon ...

Embodiment 2

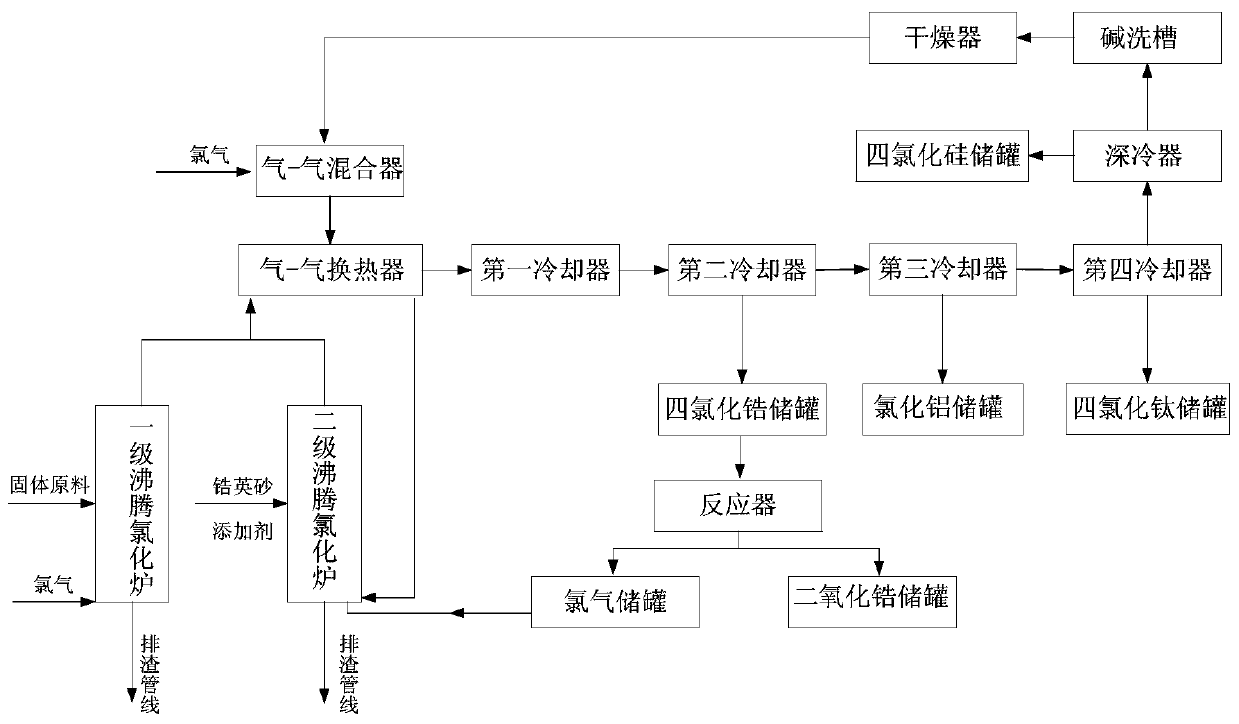

[0042] Such as figure 1 Shown, present embodiment provides a kind of preparation technology of zirconium tetrachloride, comprises the following steps:

[0043] 1) Add zircon sand, carbon reducing agent, additives, and chlorine gas into the first-stage fluidized chlorination furnace. The mass ratio of zircon sand to additive is 6:1, and the mass ratio of zircon sand to carbon reducing agent is 8:1. , the feed rate of solid material is 10kg / h, and the feed rate of chlorine gas is 25kg / h into the first-stage boiling chlorination furnace. When heated to 1200°C, a first-order chlorination reaction occurs to generate zirconium tetrachloride, tetrachloride silicon dioxide, carbon monoxide, and carbon dioxide to obtain a first gas mixture. The first gas mixture includes 10%-25% by volume of zirconium tetrachloride, 10%-35% of silicon tetrachloride, 10%-50% of carbon monoxide, 10%-20% of carbon dioxide, and a small amount of chlorinated Aluminum, titanium chloride and other impuritie...

Embodiment 3

[0066] This embodiment provides a kind of preparation technology of zirconium tetrachloride, and the difference with the preparation technology of zirconium dioxide in embodiment 2 is:

[0067] In step 1), the mass ratio of zircon sand to additive is 7:1, the mass ratio of zircon sand to carbon reducing agent is 7:1, and the feed rate of solid material added to the first-stage fluidized chlorination furnace is 100kg / h, the feed rate of chlorine gas is 22kg / h, heated to 1250°C, the additives are silicon carbide and ferrosilicon (mass ratio is 1:1), and the carbon reducing agent is petroleum coke;

[0068] The mass ratio of zircon sand and additive in step 2) is 7:1, and the feeding rate of adding solid material in the secondary boiling chlorination furnace is 10kg / h, and the chlorine gas feeding rate is 20kg / h, and the feeding rate of carbon monoxide The rate is 12kg / h, heated to 1250°C, and the additives are silicon carbide and ferrosilicon (mass ratio 1:1).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com