Track Loop Power Supply System

A technology of power supply system and track loop, applied in the direction of running track devices, power lines, vehicle parts, etc., can solve the problem of local wear and tear, grooves, uneven steel belt surface, shortened end elbows and collector shoe carbon. problems such as the service life of the skateboard, to achieve the effect of simple and reliable structure and low maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below by means of specific embodiments:

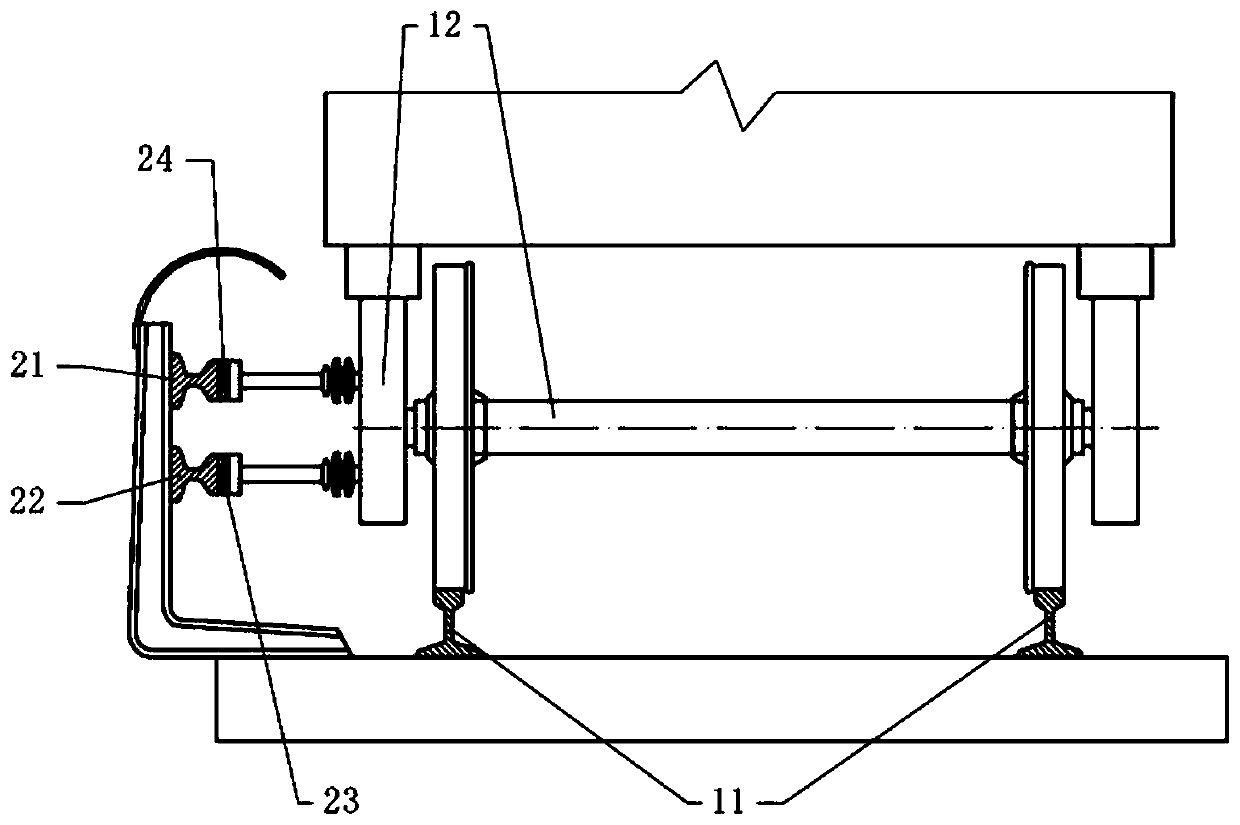

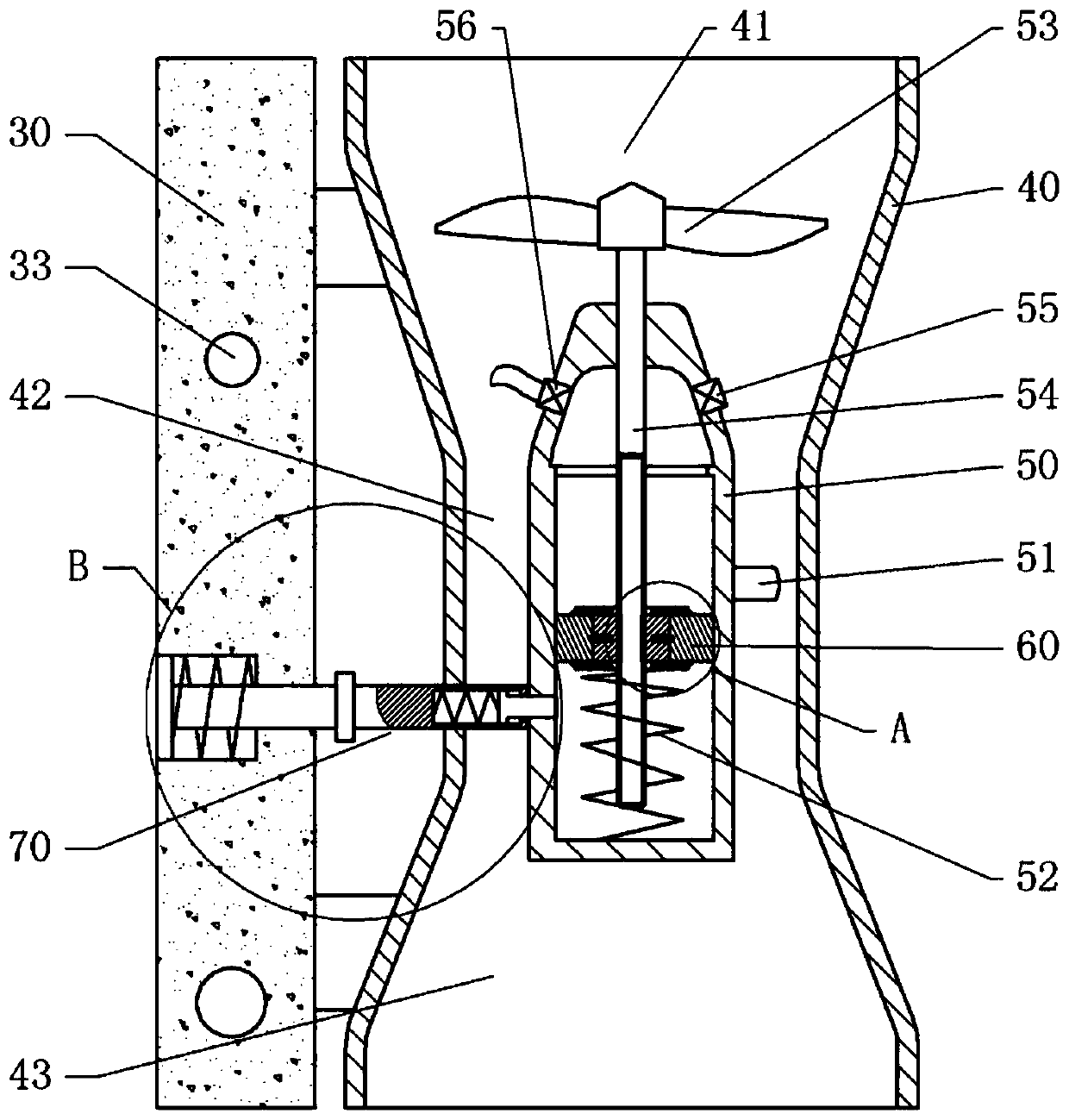

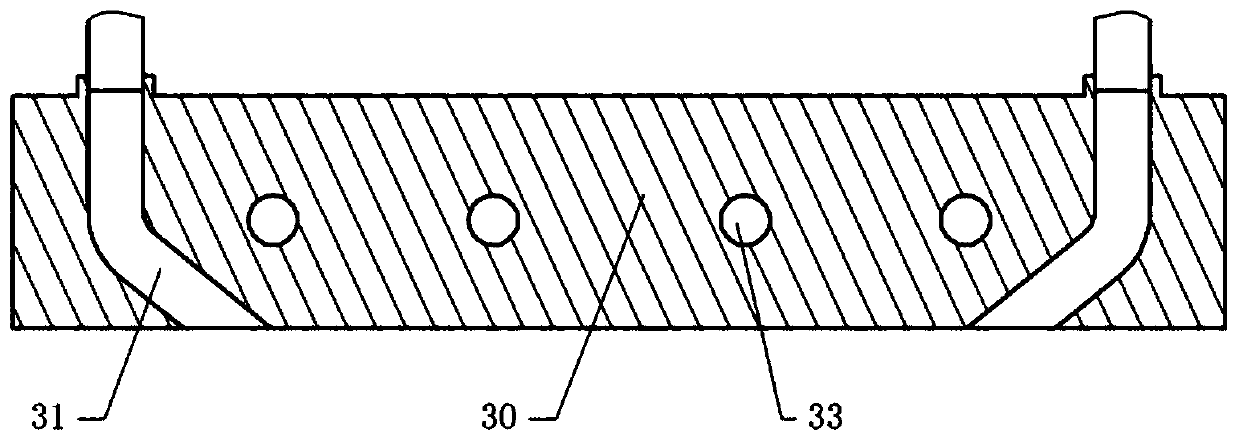

[0033] The reference signs in the drawings of the description include: running rail 11, bogie 12, traction rail 21, return rail 22, return shoe 23, traction shoe 24, carbon slide plate 30, air blowing hole 31, heat dissipation channel 33, air duct 40, Inlet section 41, throat 42, diffuser section 43, air box 50, spoke 51, first compression spring 52, fan blade 53, rotating shaft 54, intake check valve 55, outlet check valve 56, piston 60, drive block 61. Mounting hole 62, fourth spring 63, steel ball 64, baffle plate 65, limit rod 70, outer rod 71, inner rod 72, second compression spring 73, third compression spring 74, cavity 75, communication hole 76.

[0034] The track loop power supply system of this embodiment is as figure 1As shown, integral insulation support is installed on the track bed next to the vehicle running rail 11, and a protective cover is installed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com