Mounting structure of plastic fuel tank fuel pipe clamp

A technology of plastic fuel tanks and fuel pipe clamps, which is applied to the layout combined with the fuel supply of internal combustion engines, power devices, transportation and packaging, etc. It can solve the problems that the studs cannot be fixed stably and reliably, and achieve convenient and quick installation, easy deformation, The effect of preventing shedding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

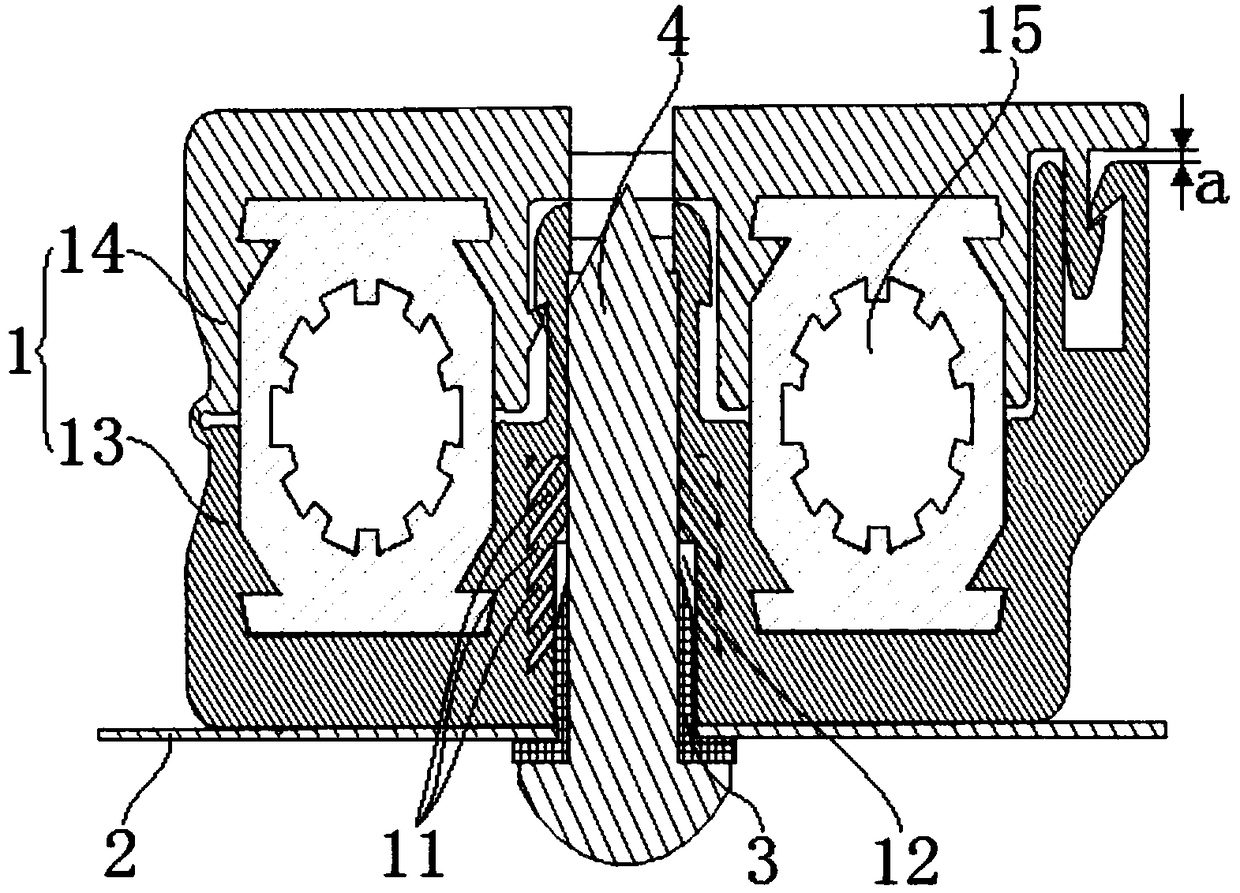

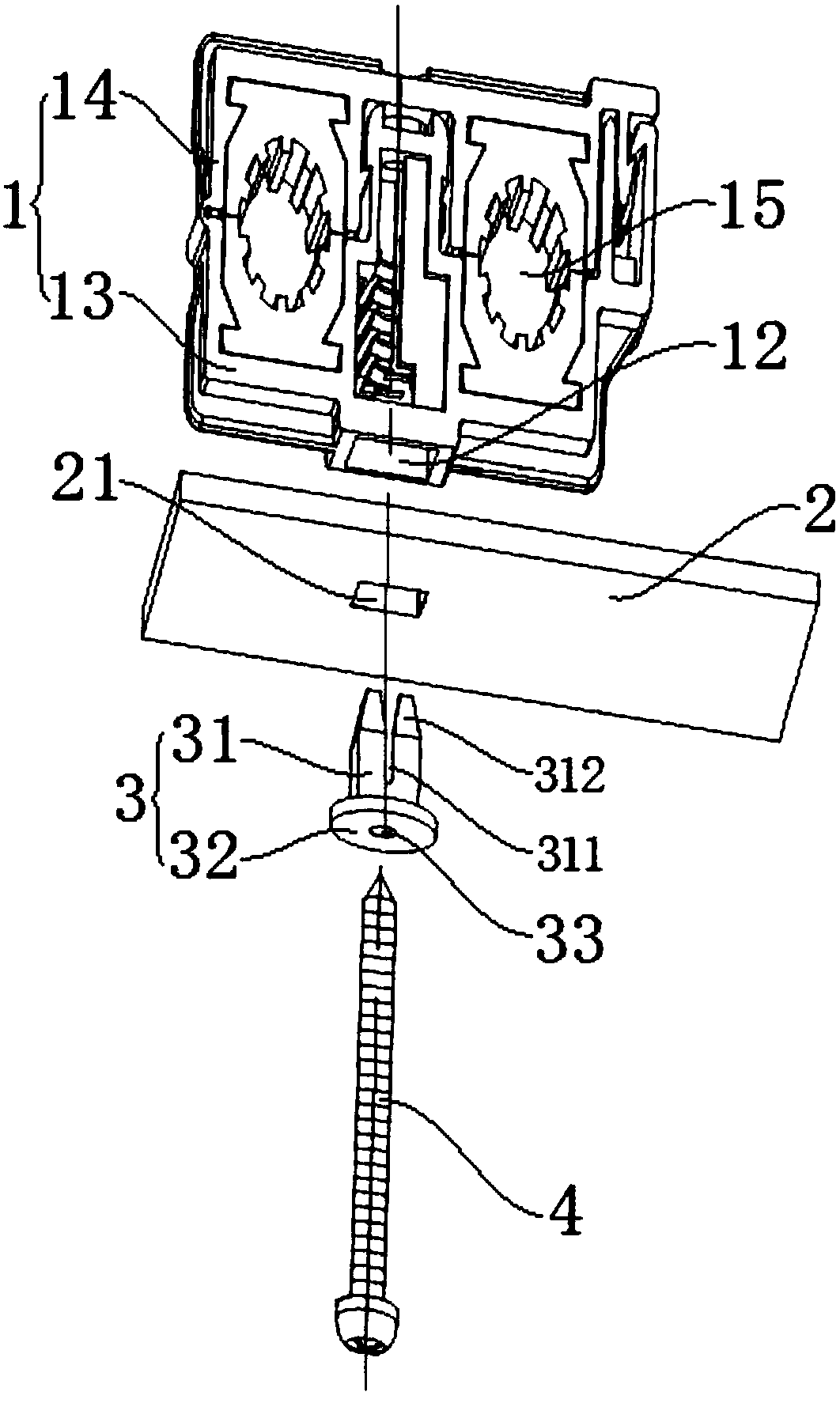

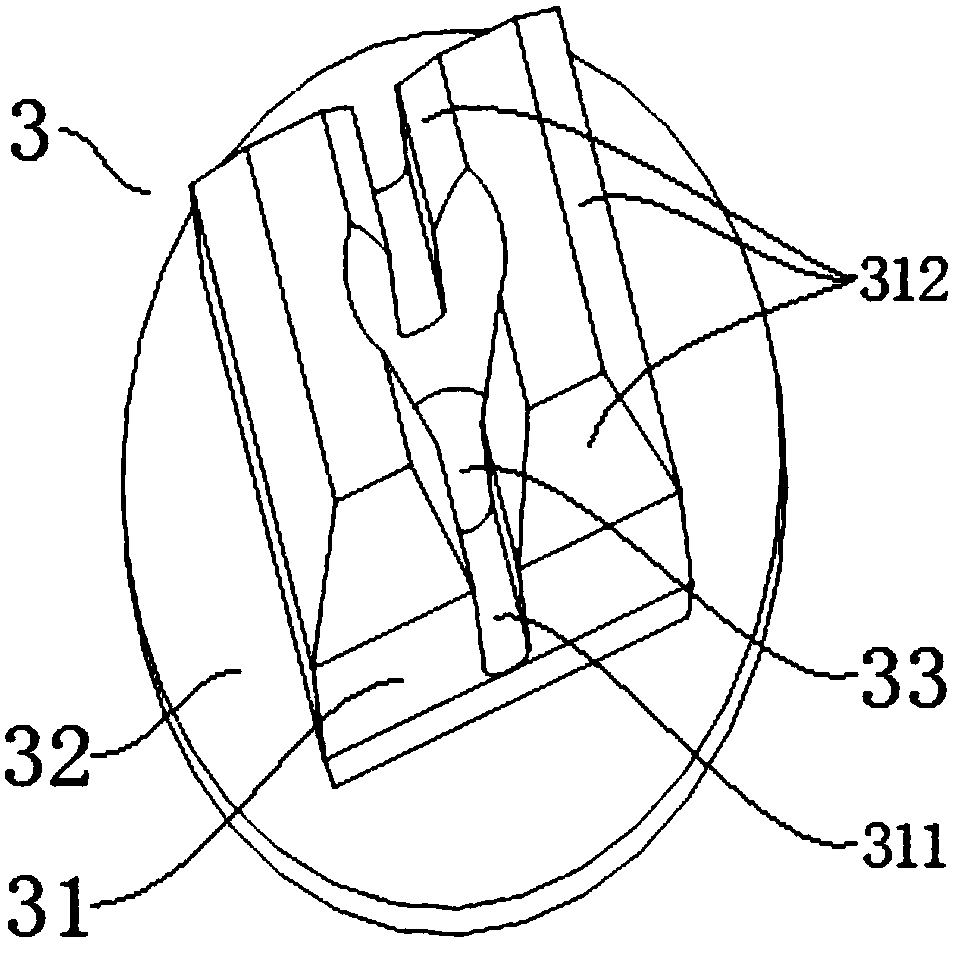

[0024] see Figure 1 to Figure 3 The shown installation structure of a plastic fuel tank fuel pipe clip includes a fuel pipe clip 1, which is characterized in that: it also includes a screw seat 3 that cooperates with the edge part 2 of the plastic fuel tank and is used to limit the position of the fuel pipe clip 1. The limiting screw seat 3 is also a screw 4 that is mated with the fuel pipe clamp 1 . By cooperating with the screw seat 3 on the edge part 2 of the plastic fuel tank, the fuel pipe clip 1 can be fixed on the edge part 2 of the plastic fuel tank through the screw seat 3 and the screw 4, which can ensure the reliable connection between the fuel pipe clip 1 and the edge part 2 of the plastic fuel tank, It can also improve the strength of the matching parts, and can also limit the position of the fuel pipe clip 1 to prevent the fuel pipe cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com