Industrial spraying robot

A spraying robot and industrial technology, applied in the direction of manipulators, manufacturing tools, etc., can solve the problems of larger occupied area of enterprises, longer production line length, unfavorable development of enterprises, etc., and achieve the goal of reducing occupied area, reducing length and suitable for promotion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

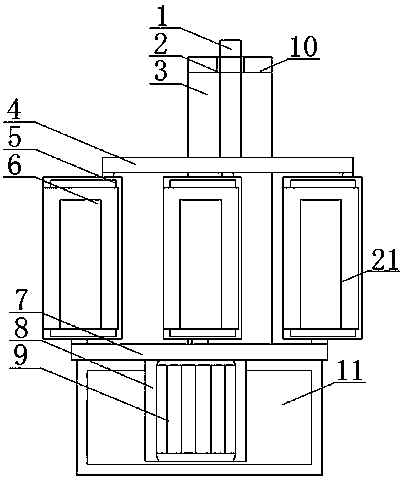

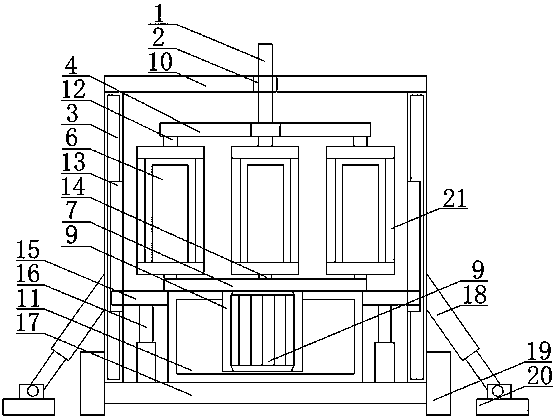

Image

Examples

Embodiment Construction

[0015] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

[0016] refer to Figure 1-3 , an industrial spraying robot, including a base plate 17, support plates 3 are fixed on both sides of the upper end of the base plate 17, which is convenient for supporting, and one side of the two support plates 3 is provided with a support device, which is stably supported and convenient for spraying. The upper end of a support plate 3 is fixed with a partition 10, the partition 10 is provided with a through hole 2, and the through hole 2 is provided with a vertical rod 1 to facilitate the movement and rotation of the vertical rod 1, and the lower end of the vertical rod 1 is fixed with a second vertical rod 1. A rotating part 4 is conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com