A fully automatic volume-controlled feeding device for chemical raw materials

A technology for chemical raw materials and feeding devices, applied in feeding devices, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of manual operation, inability to control the amount of feeding and feeding, and inability to achieve high output with low energy consumption, etc. achieve the effect of increasing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

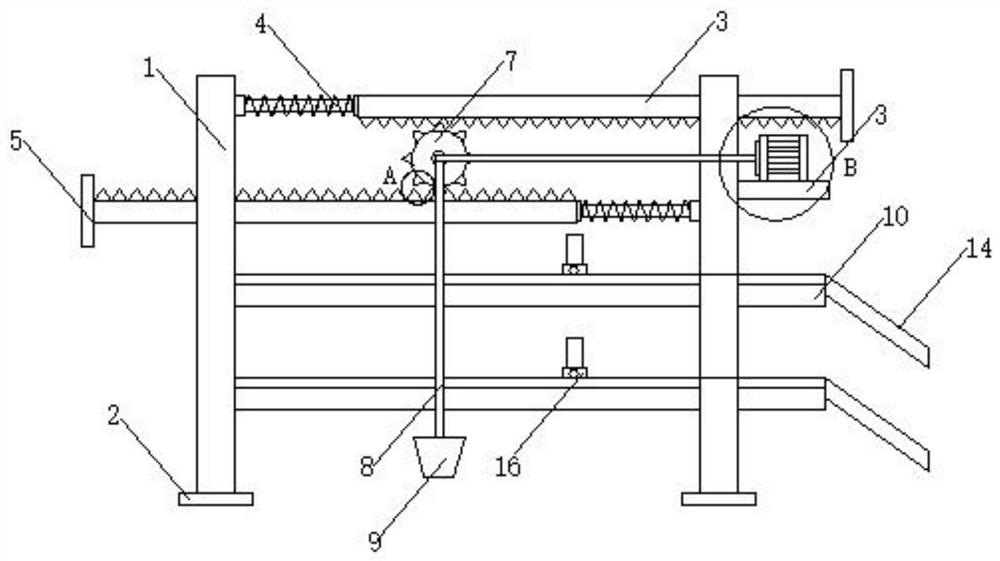

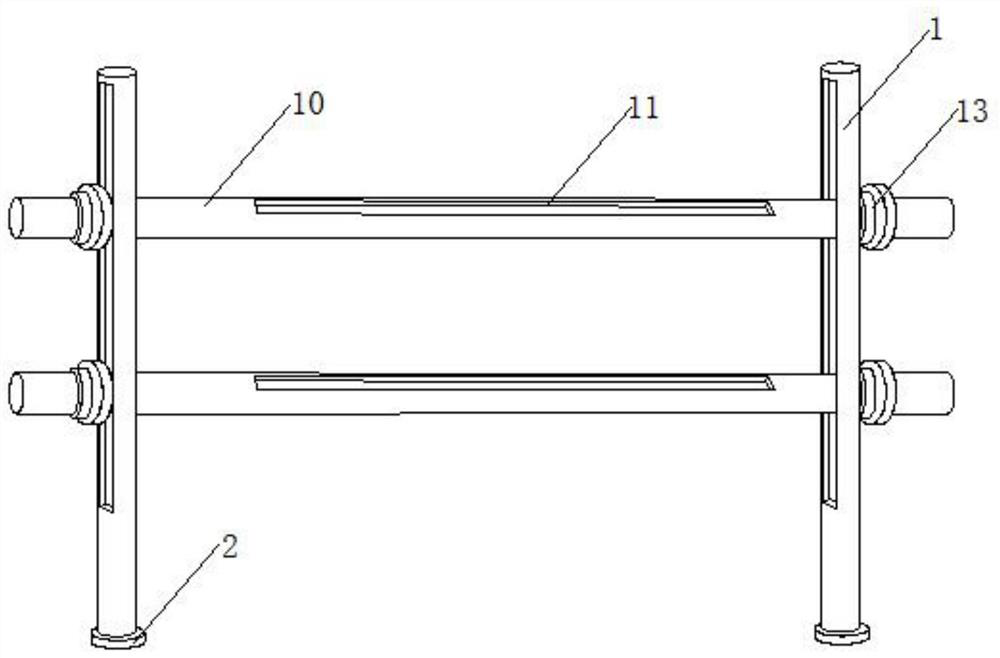

[0024] see Figure 1-6 As shown, a fully automatic controlled feeding device for chemical raw materials includes a column 1, a horizontal plate 3, a spring 4, a roller 7, a feeding hopper 9, a motor 12, a bottom plate 15, a connecting block 18 and a screw hole 21, and the column The bottom end of 1 is provided with a round platform 2, the column 1 is embedded with a chute 11, a spring 4 is provided on one side of the outer wall of the column 1, and the other end of the spring 4 is connected with a horizontal plate 3, and the other end of the horizontal plate 3 One end runs through another column 1, and a roller 7 is clamped between adjacent horizontal plates 3, and both the horizontal plate 3 and the roller 7 are provided with toothed edges 6, by setting the toothed edges, the distance between the rollers and the horizontal plate will be The toothing is tighter, two groups of crossbars 10 are arranged under the lower horizontal plate 3, the upper end of the crossbar 10 runs th...

Embodiment 2

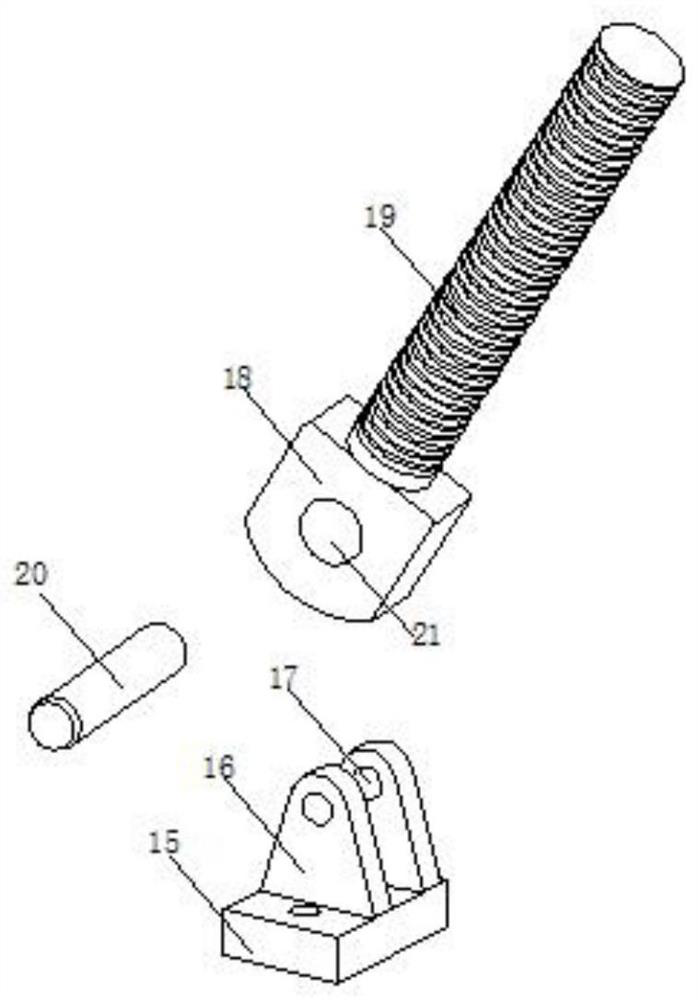

[0026] Compared with Embodiment 1, the horizontal plate 3 is provided with a clip 5 through one end of the column 1, and the height of the clip 5 is higher than the thickness of the horizontal plate 3, and the clip 5 and the horizontal plate 3 are vertically arranged, By setting the clip 5, there is a limited range for the movement of the horizontal plate 3. Two sets of connecting ropes 8 are connected to the roller 7, the bottom end of one side connecting rope 8 is located on the motor 12, and the bottom of the motor 12 is also provided with a horizontal plate 3, and the bottom end of the other side connecting rope 8 is connected with a feeding hopper 9 , by setting the motor 12, the feeding hopper 9 can be stretched by the rotation of the motor 12, and the motor 12 also provides a power source for each component in the device at the same time. A connecting block 18 is clipped on the clamping plate 16, and a movable rod 19 is connected above the connecting block 18, and the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com