A flue gas purification system involving multiple processes and a control method thereof

A flue gas purification system and multi-process technology, applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve problems such as stable fluctuations in the amount of activated carbon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0096] Exemplary embodiments will be described in detail herein, examples of which are illustrated in the accompanying drawings. Where the following description refers to the drawings, the same numerals in different drawings refer to the same or similar elements unless otherwise indicated. The implementations described in the illustrative examples below are not intended to represent all implementations consistent with the present invention. Rather, they are merely examples of apparatus and methods consistent with some aspects of the invention as recited in the appended claims.

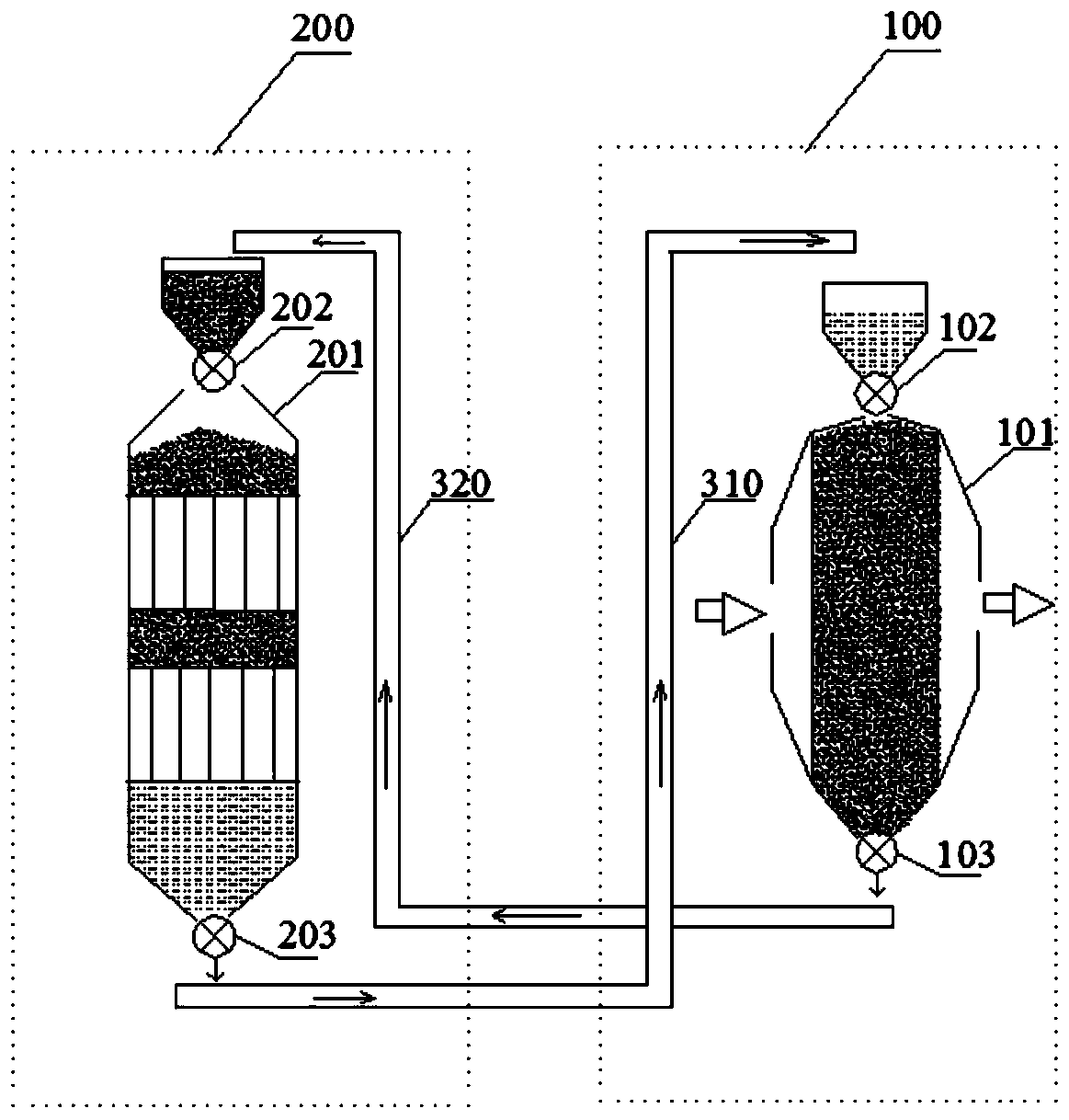

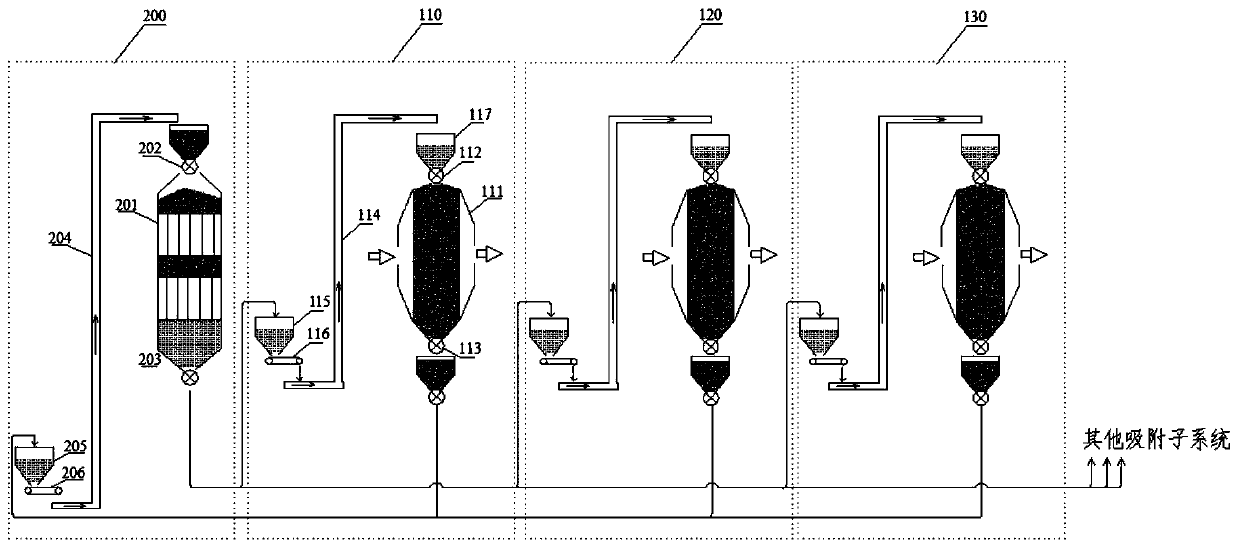

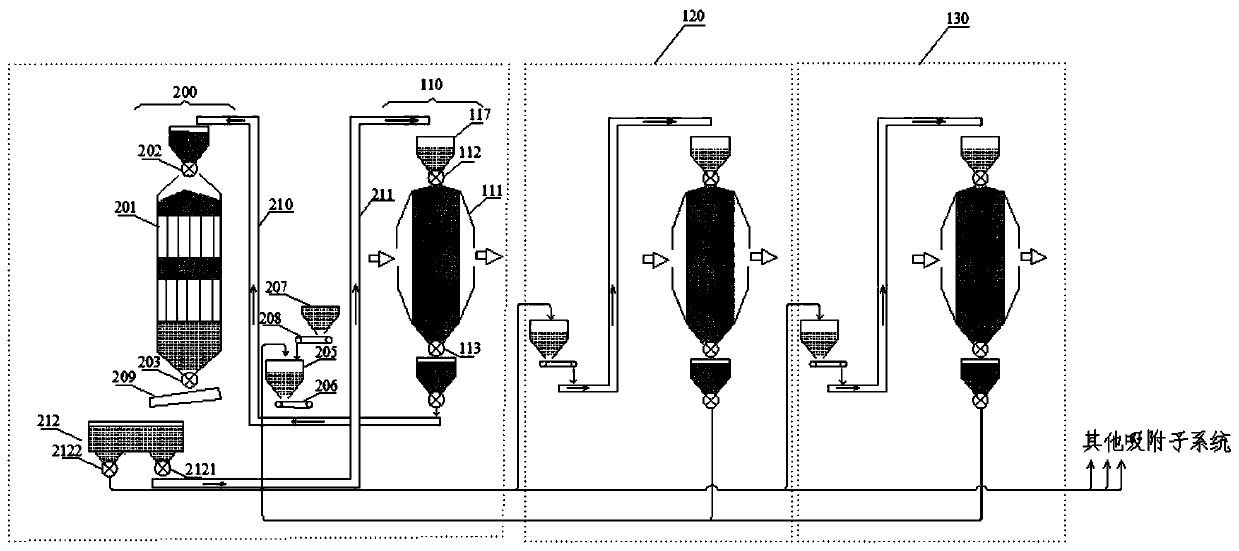

[0097] figure 2 A flue gas purification system involving multiple steps is shown, see figure 2 , the flue gas purification system includes:

[0098] A plurality of adsorption subsystems (110 / 120 / 130, etc.) respectively arranged in each flue gas discharge process, a centralized analysis subsystem 200 corresponding to the plurality of adsorption subsystems, and a transportation subsystem (not shown ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com