Device and method for testing dynamic hydrogen brittleness of metal material under constant strain amplitude

A technology for metal materials and test devices, which is used in measuring devices, analyzing materials, and testing the strength of materials by applying repetitive force/pulsation force. It can solve unseen problems and achieve the effect of avoiding corrosion and accurate hydrogen embrittlement performance.

Inactive Publication Date: 2018-09-18

武汉钢铁有限公司

View PDF23 Cites 24 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0021] To sum up, 18 documents related to the research content of this project were found, and the test methods are all static and quasi-static hydrogen em

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

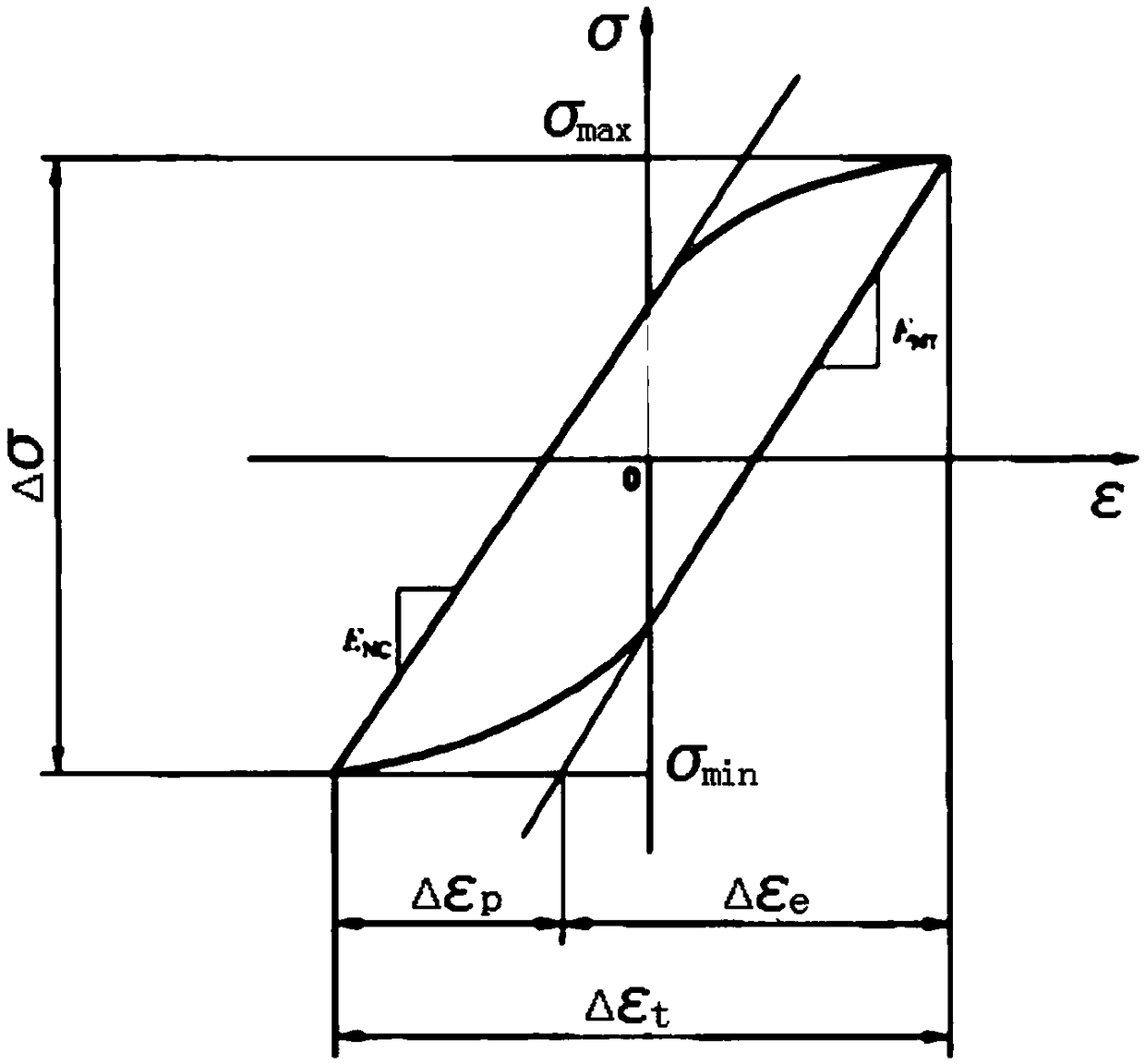

The invention discloses a device and method for testing the dynamic hydrogen brittleness of a metal material under a constant strain amplitude. The device comprises a clamp, a medium groove, an extensometer, a dynamic working device, an electrochemical work station, and a controller. The clamp comprises a first clamp body and a second clamp body. A hydrogen filling medium is arranged in the mediumgroove. The first clamp body and the second clamp body are used to clamp a sample from two sides of the sample. The sample is soaked in the hydrogen filling medium. A reference electrode and an auxiliary electrode are arranged in the hydrogen filling medium. The reference electrode, the auxiliary electrode, and the sample are connected to the electrochemical work station. The first clamp body isconnected to the dynamic working device. The second clamp body is fixedly arranged on a base. The extensometer is connected to the surface of the sample. The extensometer and the dynamic working device are connected to the controller. The provided device and method can more practically measure the hydrogen brittleness of a material under a dynamic load; a three dimensional evaluation system including constant strain amplitude dynamic load, online hydrogen filling current, and cycle life is established, and the hydrogen brittleness of a detected material can be measured more accurately.

Description

technical field [0001] The invention relates to the technical field of material testing, in particular to a device and method for testing the dynamic hydrogen embrittlement performance of a metal material with equal strain amplitude. Background technique [0002] Hydrogen embrittlement is a kind of environmental embrittlement caused by the interaction of material-environment-stress, and it is a form of hydrogen-induced material deterioration. The delayed fracture caused by it is a main factor hindering the high strength of steel used in machinery manufacturing. The delayed fracture of high-strength bolt steel is a very typical example. For example, in the early 1980s, General Motors of the United States had 27 traffic accidents due to the delayed fracture of two 12.9-grade bolts installed on the bottom control frame of the car, and finally replaced these two bolts on 6.4 million cars. bolt. The rapid development of the automobile industry and the continuous advancement of ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N3/32G01N3/02G01N3/04

CPCG01N3/02G01N3/04G01N3/32G01N2203/0005G01N2203/0017G01N2203/0067G01N2203/024G01N2203/028G01N2203/0282G01N2203/0458G01N2203/0682

Inventor 薛欢毛新平刘念刘冬熊飞刘永前周剑华陈勇

Owner 武汉钢铁有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com