Process and production line for producing quicklime and aluminum hydroxide from waste

A technology of aluminum hydroxide and quicklime, applied in the direction of alumina/aluminum hydroxide, etc., to achieve good economic benefits, pollution control, and broad market growth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

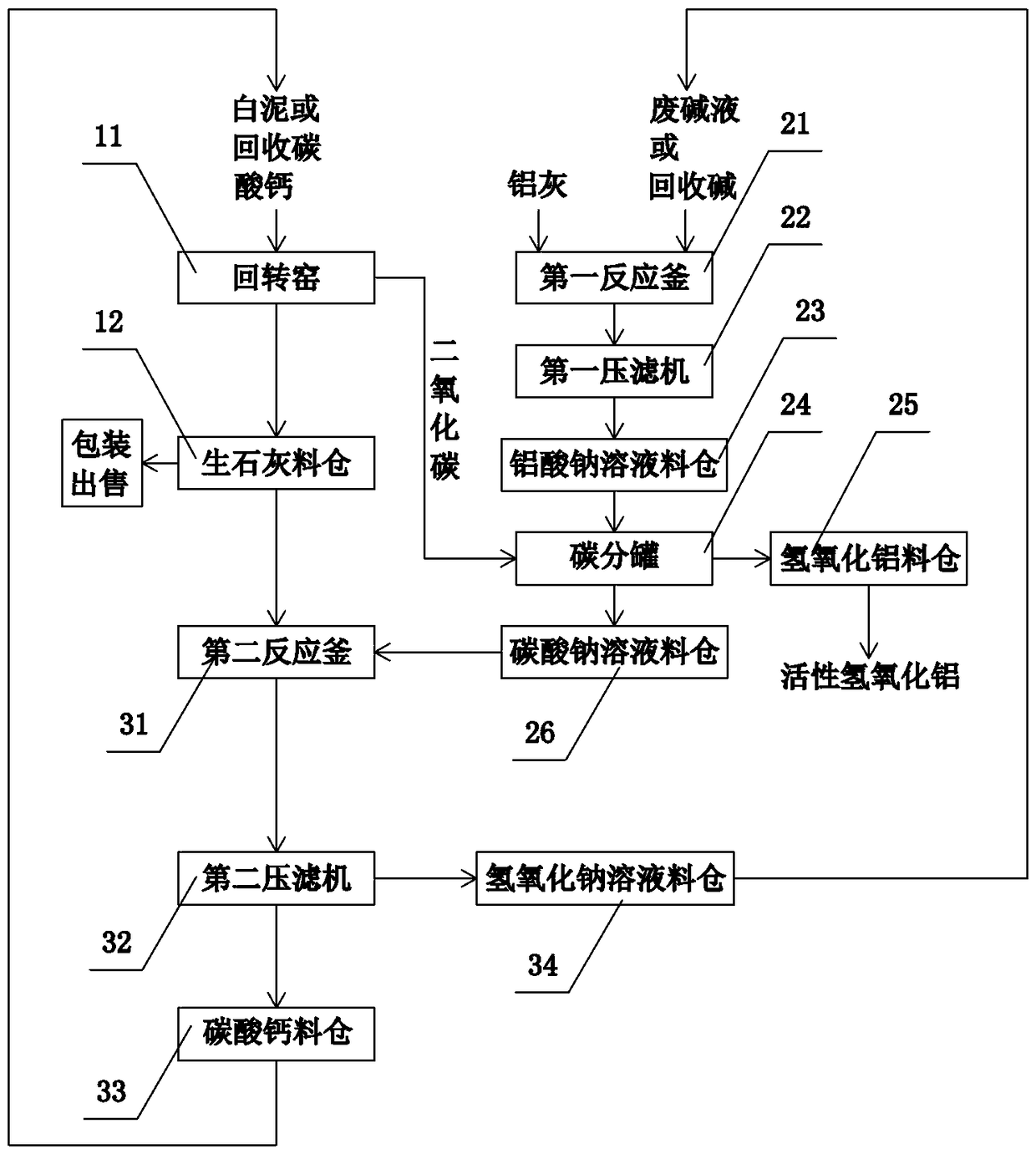

[0032] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

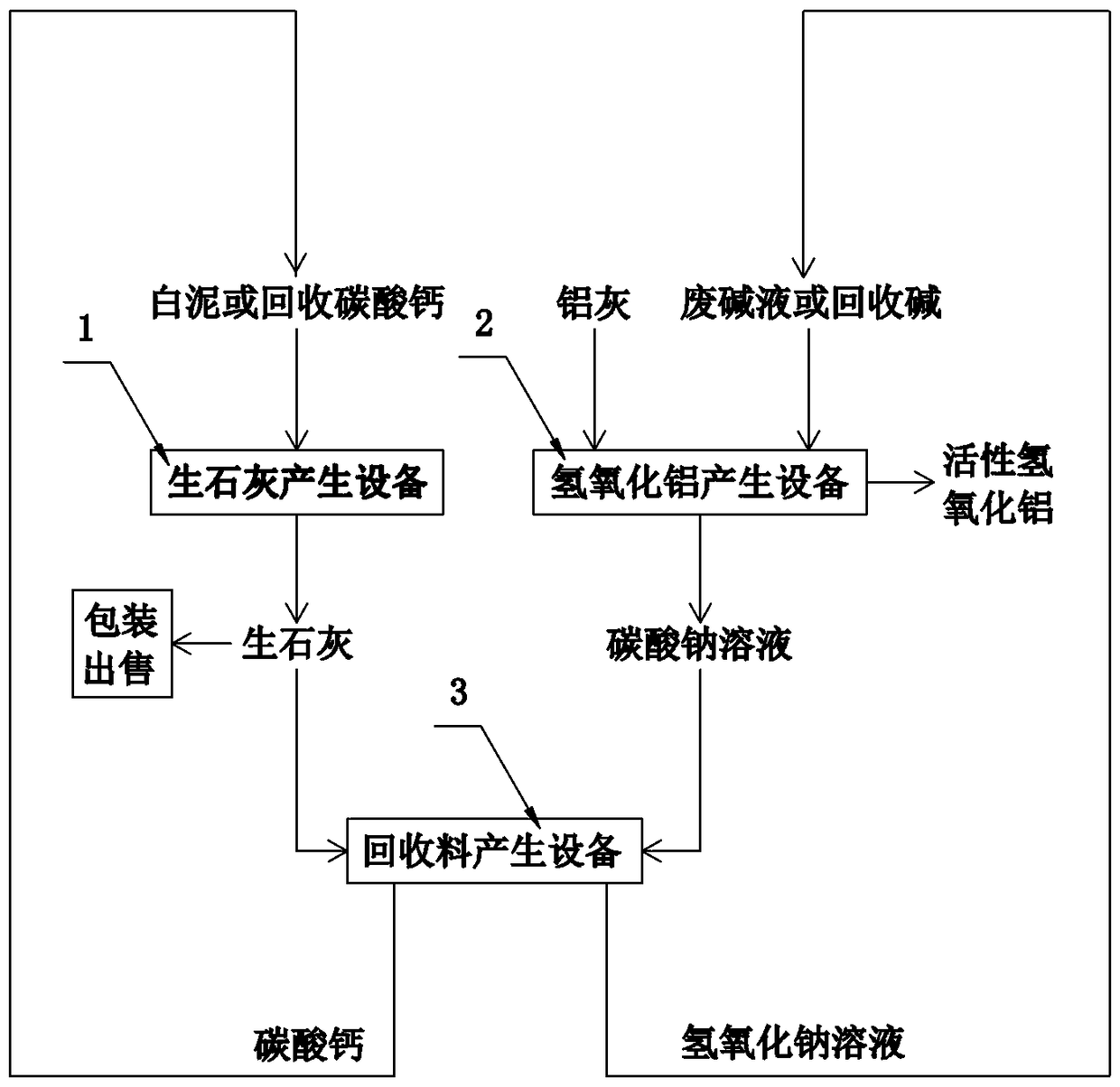

[0033] refer to figure 1 , figure 2 . A production line for producing quicklime and aluminum hydroxide by using waste, including quicklime producing equipment 1, aluminum hydroxide producing equipment 2, and recycled material producing equipment 3. in,

[0034] Quicklime production equipment 1 includes a rotary kiln 11 for calcining lime mud or recovering calcium carbonate, and a quicklime silo 12 connected to the discharge end of the rotary kiln 11; the specific use is: to transfer lime mud or recovered calcium carbonate to the rotary kiln 11 for Calcining at a temperature of about 1000°C for about 30 minutes to obtain quicklime, then convey the quicklime out and cool it down to about 300°C through a cooler, and put it in the quicklime silo 12 for storage. The quicklime can be directly packaged and sold, or can be continuously used to produce Recycl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com