Pipe fitting traction rotation precision machining device

A processing device and technology for pipe fittings, which is applied in the field of pipe fitting traction and rotation precision processing devices, can solve the problems of poor processing accuracy, poor constraints, and inability to process at any position, so as to improve processing accuracy and efficiency and meet processing needs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

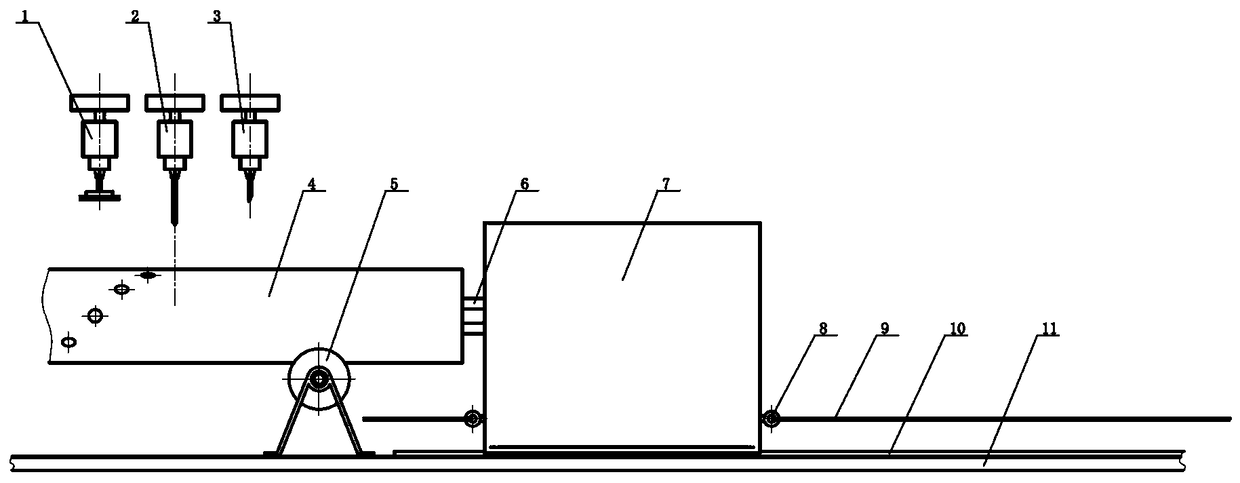

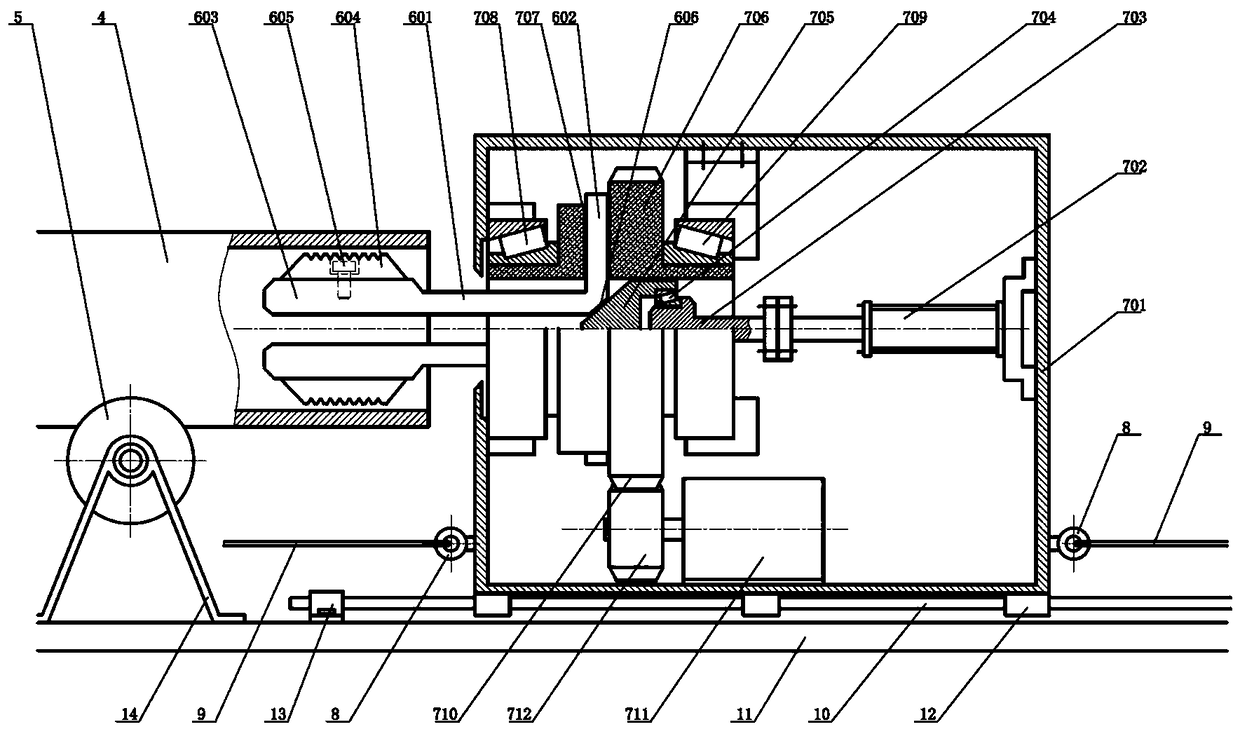

[0016] Embodiment 1: as figure 1 The pipe processing device shown has the precise effect of pulling and rotating. The device includes a pipe fitting supporting traveling mechanism, a pipe fitting processing mechanism, a pipe fitting fixing traction mechanism and the like.

[0017] Wherein, the pipe supporting traveling mechanism is that a V-shaped support roller 5 is installed on the support 11 through the support roller fixing seat 14, and the pipe fittings are matched and clamped in the V-shaped grooves of multiple groups of V-shaped support rollers 5 . Each V-shaped idler 5 can rotate and support along with the translation of the pipe.

[0018] A translation guiding mechanism is arranged between the clamping and rotating mechanism 7 and the bracket 11 , and the pulling mechanism is fixed on the bracket 11 and connected with the clamping and rotating mechanism 7 . The translation guiding mechanism is that the rail 10 along the axial direction is fixed on the bracket 11 thr...

Embodiment 2

[0025] Embodiment 2: On the basis of Embodiment 1, each inner fixture 6 is provided with a return structure. For example, a clamping groove is provided outside the clamping axial rod 601 of each internal clamping clamp 6 and a ring-shaped shrinking spring is sleeved therein. Alternatively, a clamp radial rod 602 of each inner clamp 6 is sleeved with a compression spring capable of contracting inward, and the outer end of the compression spring is supported in a corresponding block or spring seat on the rotating body 706 .

Embodiment 3

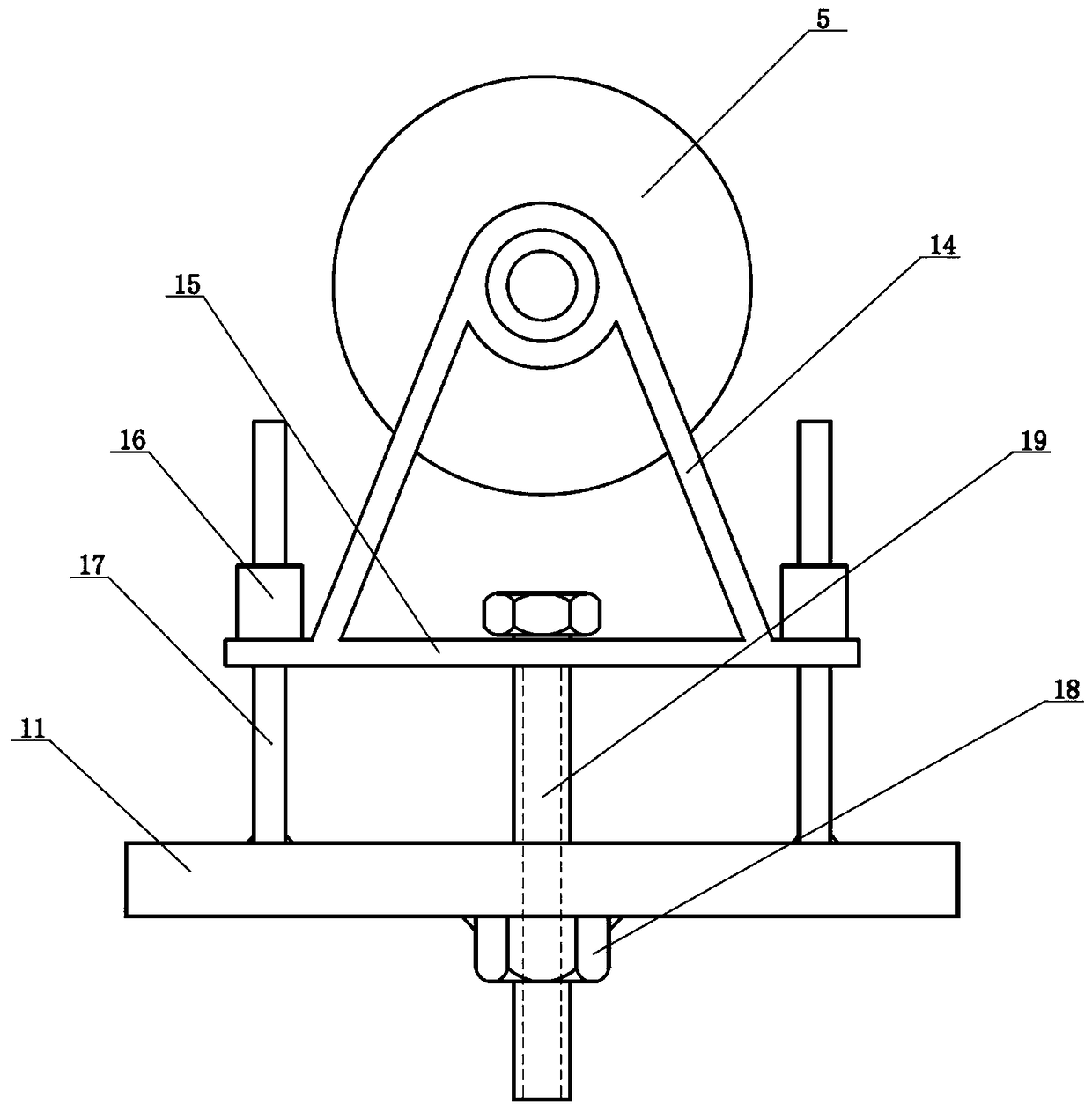

[0026] Embodiment 3: On the basis of Embodiment 1, the fixing seat of the V-shaped supporting wheel 5 is provided with a height adjustment structure, and its purpose is to meet the processing requirements of cylindrical pipe fittings with different diameters. For the cylindrical pipe fittings 4 with different diameters, since the height of the shaft center is different, the purpose of adjusting the height of the shaft center of the pipe fittings with different diameters is achieved by adjusting the support height of the V-shaped support roller 5 . see image 3As shown, the height adjustment structure of the supporting wheel fixing seat 14 is that a movable base 15 is provided on the lower side of the supporting wheel fixing seat 14, and the four corners of the movable base 15 are respectively fixed with vertical guide pipes 16, and at the same time, corresponding positions on the bracket 11 Four vertical guide rods 17 are fixed, and each guide rod 17 is matched and sleeved in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com