Plug-in module and vacuum cleaner with the plug-in module

A plug-in head, plug-in connection technology, applied in vacuum cleaners, suction hoses, household appliances, etc., can solve the problems of unstable connection and low assembly efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

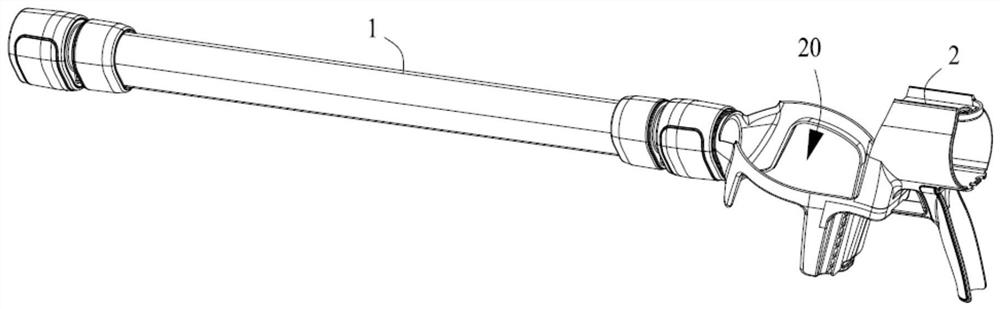

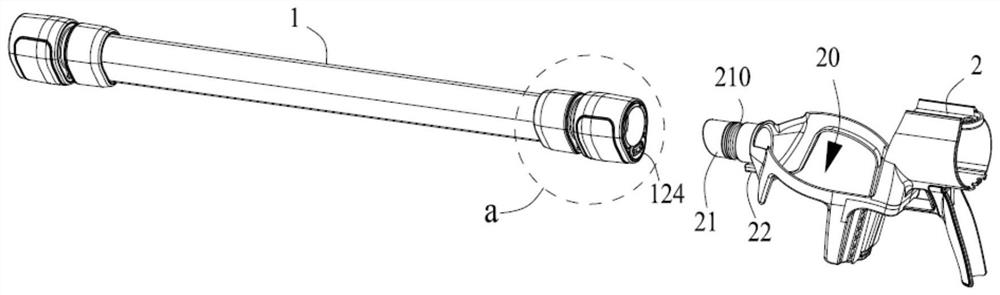

[0029] The present invention will be described in detail below with reference to the various embodiments shown in the accompanying drawings. Figure 1 to Figure 15 As shown, there are some preferred embodiments of the present invention.

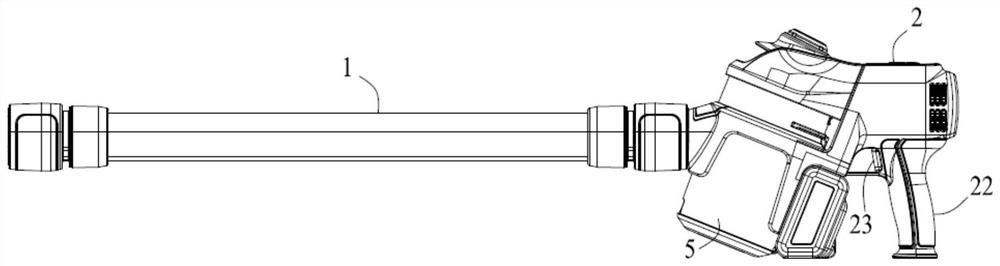

[0030] The invention discloses a vacuum cleaner. Specifically, in this embodiment, the vacuum cleaner involved is a hand-held vacuum cleaner. combine figure 1 , figure 2 , Figure 14 , Figure 15 As shown, in this embodiment, the hand-held vacuum cleaner includes a vacuum cleaner body 2 and a dust cup 5 arranged in the vacuum cleaner body 2; wherein, the vacuum cleaner body 2 has an accommodating cavity (not marked in the figure) with an opening 20 formed on the upper side. The cup 5 is inserted into and fixed in the vacuum cleaner body 2 from the upper opening 20 of the accommodating cavity.

[0031] In the present invention, the dust cup 5 can be matched with the vacuum cleaner body 2 by inserting from the upper side, and the operatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com