Heat radiation and diversion cabinet

A cabinet and diversion area technology, applied in cooling/ventilation/heating renovation, electrical components, electrical equipment structural parts, etc., can solve problems such as affecting the appearance of large equipment, occupying communication equipment cabinet space, and reducing the cooling efficiency of the equipment room. , to achieve the effect of improving user perception, saving power and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

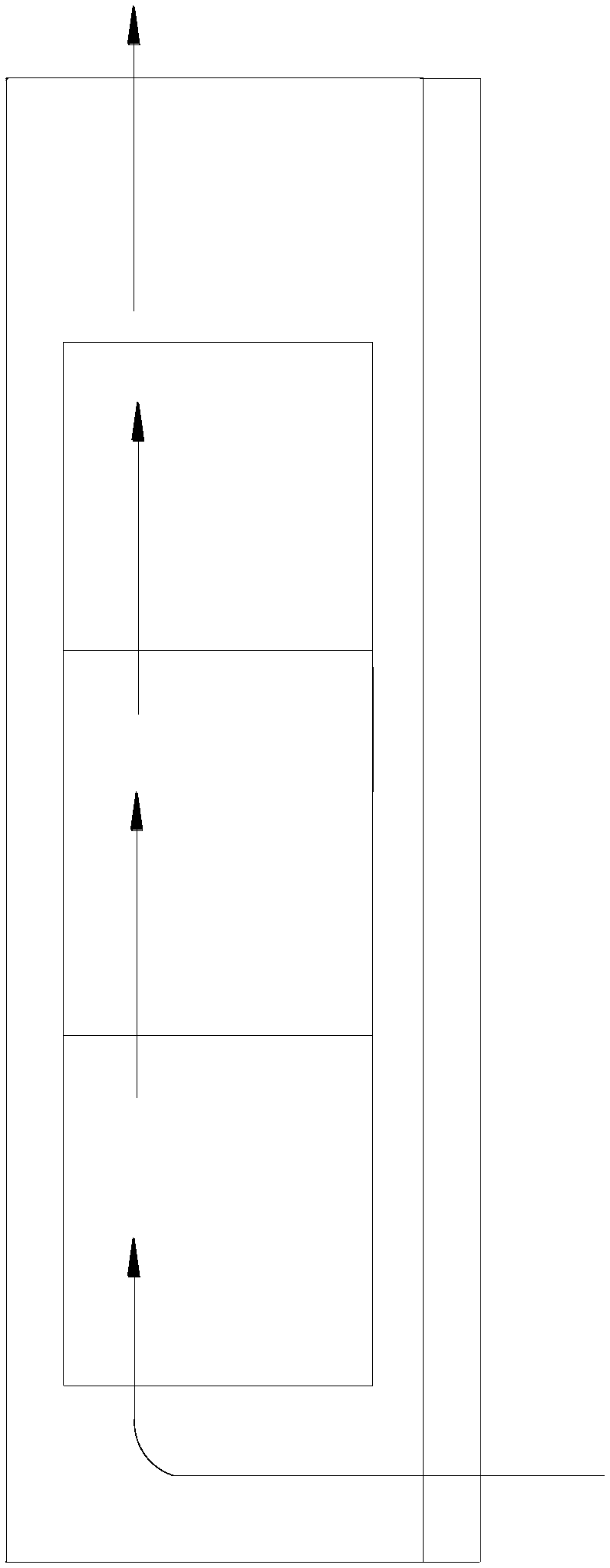

[0040] Embodiment one, see Figure 1 to Figure 6 As shown, the embodiment of the present invention provides a heat dissipation guide cabinet, including:

[0041] Cabinet 1, the inside of the cabinet 1 is provided with a multi-layer main board 10, the cabinet 1 is also provided with a first air duct 4 and a second air duct 5, and the first air duct 4 includes a The first air inlet 11, and the first air outlet 13 arranged in the middle of the cabinet 1, the second air duct 5 includes the second air inlet 14 arranged in the middle of the cabinet 1, and the second air inlet 14 arranged in the top of the cabinet 1 The second air outlet 12, the first air outlet 13 and the second air inlet 14 are arranged perpendicular to the panel of the cabinet body 1;

[0042] The partition 3 installed between the panel of the cabinet body 1 and the main board 10 , the partition 3 is arranged between the first air outlet 13 and the second air inlet 14 .

[0043]The heat dissipation guide cabinet...

Embodiment 2

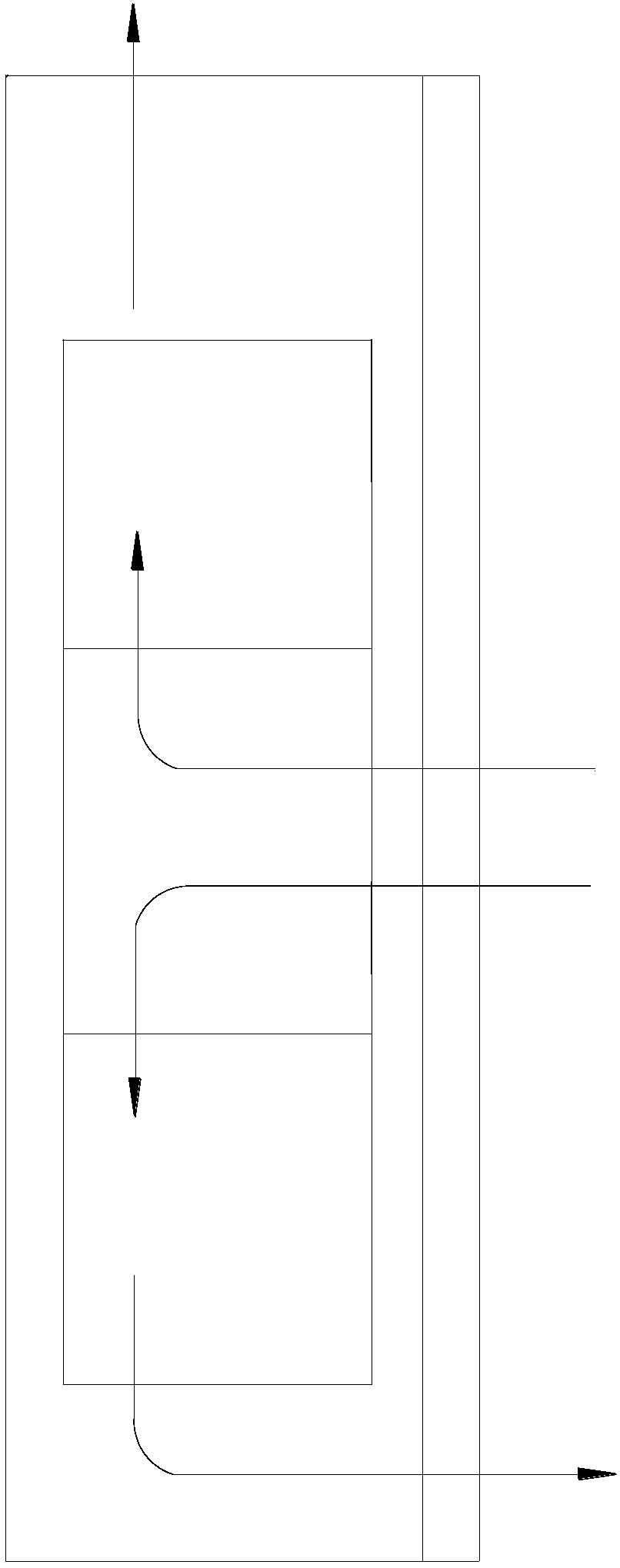

[0044] Embodiment two, on the basis of the technical solution of embodiment one, refer to Figure 1 to Figure 6 As shown, the heat dissipation guide cabinet also includes a guide device 2 arranged between the middle motherboards 10 in the cabinet body 1, and the guide device 2 includes a first guide area 21 and a second guide area 22. The first air guide area 21 is set on the first air channel 4, and the second air guide area 22 is set on the second air channel 5; by setting the air guide device 2 to guide the cold air circulation, Wherein the first guide area 21 is arranged on the first air channel 4, guides the cold air to enter from the first air inlet 11, after passing through the lower area of the lower main board 10 and the middle main board 10, the heat therein is taken out, and the first outlet The air port 13 is discharged; the second guide area 22 is arranged on the second air duct 5, and the cold air is guided to enter from the second air inlet 14, and after passi...

Embodiment 3

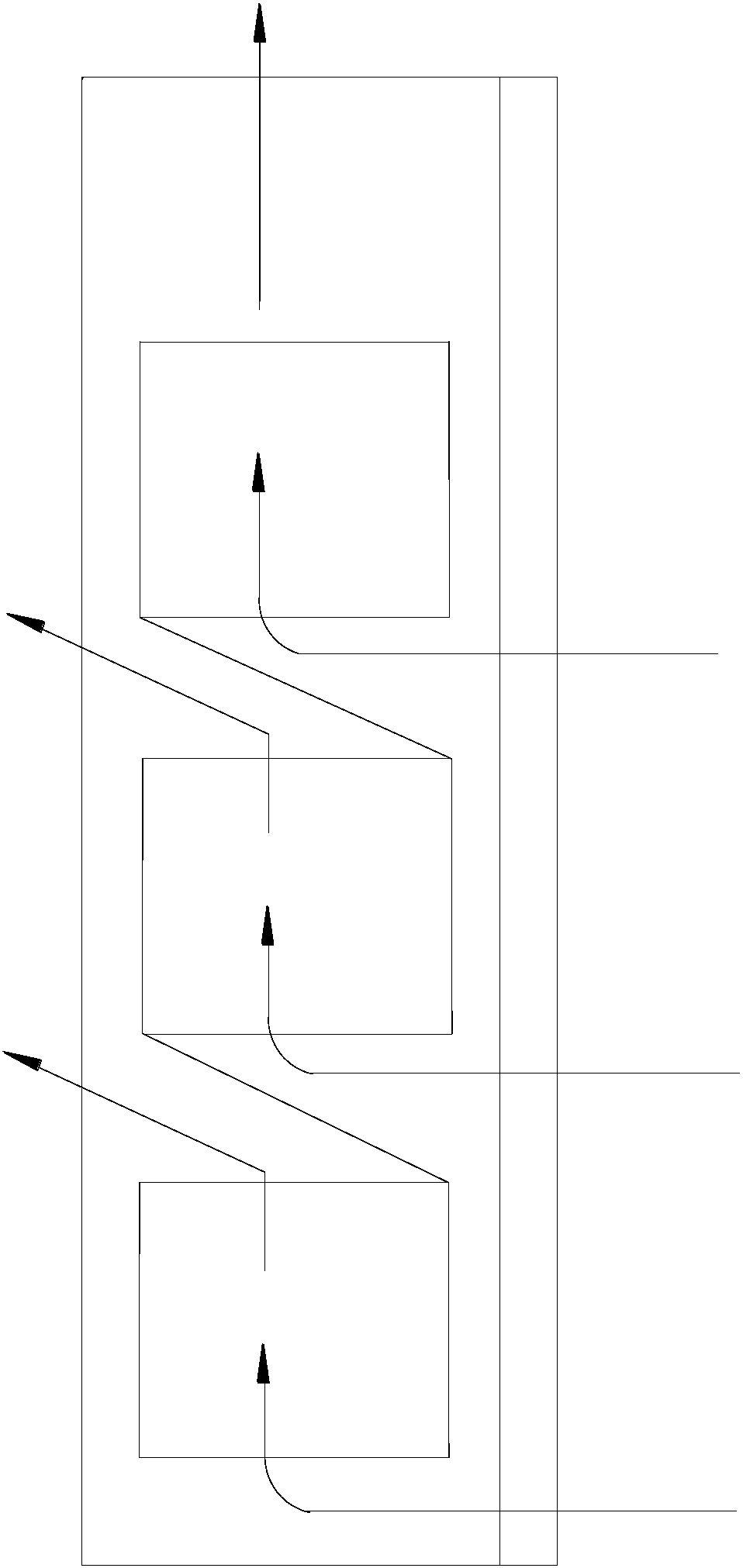

[0045] Embodiment three, on the basis of the technical scheme of embodiment two, see Figure 1 to Figure 6 As shown, the deflector 2 includes a mounting base 20, one side of the mounting base 20 is a first deflecting area 21, and the other side is a second deflecting area 22; using the mounting base 20 is convenient for the deflecting device 2 The division of the upper diversion area and the setting of each component.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com