Lithium ion battery electrolyte

A lithium-ion battery and electrolyte technology, which is applied in the direction of lithium batteries, secondary batteries, organic electrolytes, etc., can solve the problems of insufficient cycle performance of flame-retardant electrolytes, and achieve good cycle performance, flame-retardant safety, and stable cycle performance , The effect of small change in internal resistance

Active Publication Date: 2018-09-14

NANTONG CAPCHEM ELECTRONICS MATERIALS CO LTD

View PDF3 Cites 11 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] The technical problem to be solved by this invention is to provide an improved lithium-ion battery electrolyte for the insufficient cycle performance of the flame-retardant electrolyte in the prior art

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

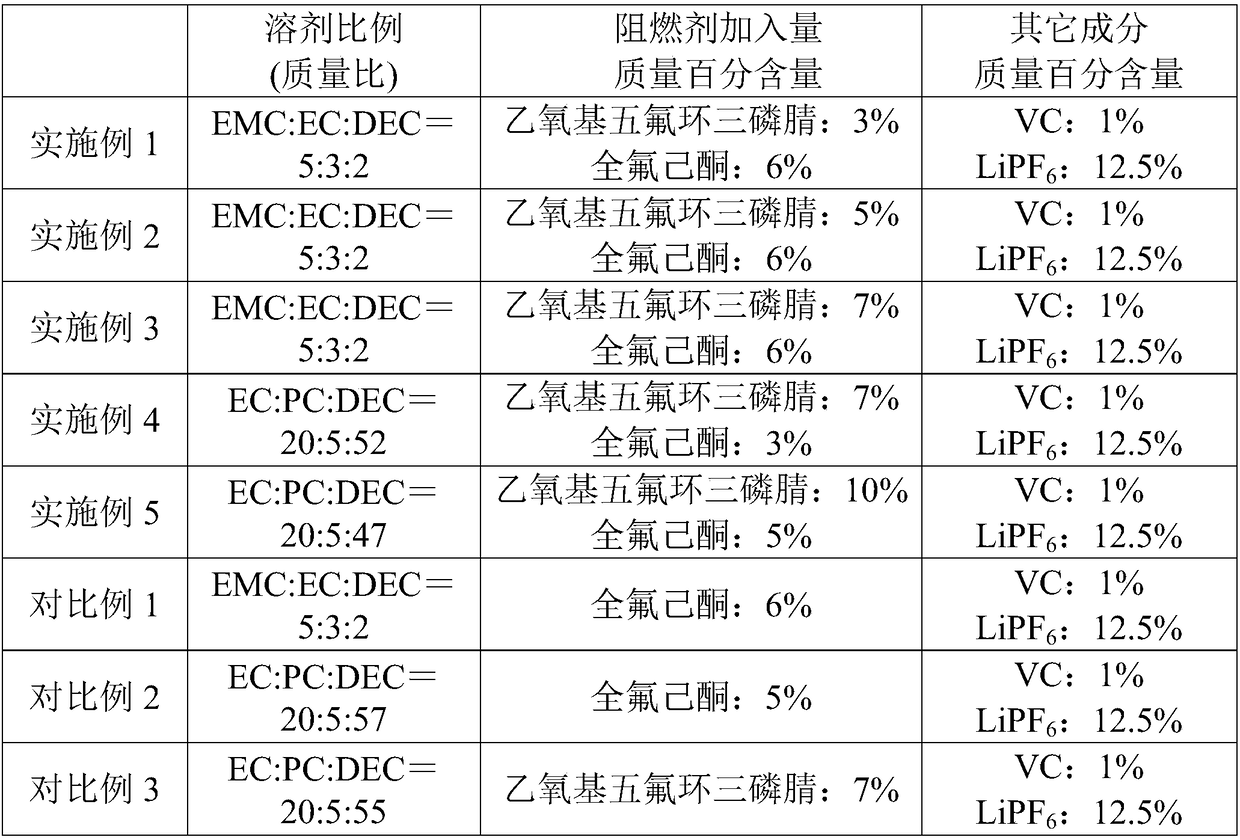

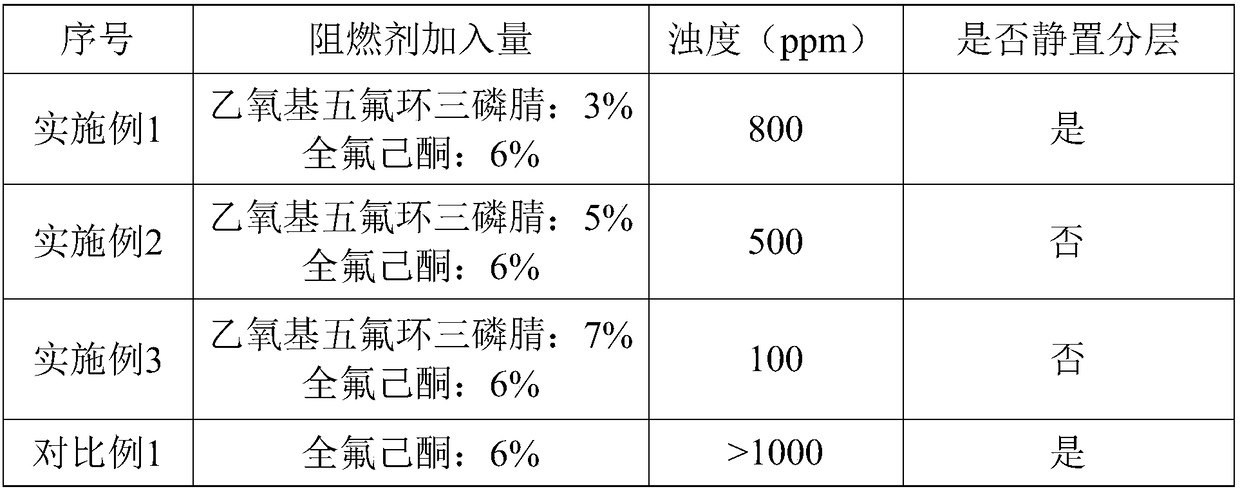

[0032] In a nitrogen-protected glove box (moisture 6 ), then add other additives and flame retardant additives of the specified species and content in Table 1, and obtain the lithium-ion battery electrolyte of embodiment 1 after stirring.

Embodiment 2~5

[0034] Under the same conditions as in Example 1, the ingredients of each example specified in Table 1 are formulated to obtain the lithium-ion battery electrolytes of Examples 2 to 5 respectively.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

In order to solve the problem that in the prior art, electrolyte cannot simultaneously realize the electrochemical performance such as flame retardant performance and circulation cycle, the inventionprovides lithium ion battery electrolyte. The lithium ion battery electrolyte is prepared from lithium salt, an organic solvent and additives, wherein the additives include a phosphonitrile compound and perfluoro(2-methyl-3-pentanone). The lithium ion battery electrolyte provided by the invention has good cycle performance and flame retardant safety; a lithium ion battery using the electrolyte hasstable cycle performance at normal temperature and 45 DEG C; air expansion cannot occur when the lithium ion battery is stored in a 60-DEG C heat box; the internal resistance is small; good storage performance and cycle performance are maintained.

Description

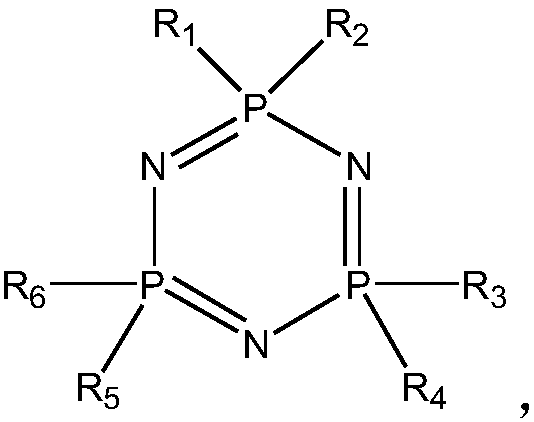

technical field [0001] The invention belongs to the technical field of lithium-ion battery electrolytes, in particular to a lithium-ion battery electrolyte containing two flame-retardant additives. Background technique [0002] Lithium-ion batteries are composed of positive electrodes, negative electrodes, diaphragms, and electrolytes. Lithium-ion battery electrolytes accommodate and conduct ions between the positive and negative electrodes of the battery, enabling lithium-ion batteries to obtain high voltage and high specific energy. Guarantee of other advantages. Lithium-ion battery electrolytes are generally prepared from solvents, lithium salts, and additives in certain proportions. Lithium hexafluorophosphate (LiPF) is the most mature lithium salt used in the production of commercial lithium-ion batteries. 6 ), solvents are mainly carbonates and a small amount of carboxylic esters, such as: ethylene carbonate (EC), propylene carbonate (PC), dimethyl carbonate (DMC), e...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H01M10/0567H01M10/0525

CPCH01M10/0525H01M10/0567H01M2300/0025H01M10/052H01M10/0568H01M10/0569H01M10/4235H01M2300/0028Y02E60/10

Inventor 殷俊葛晓军郝敬磊丁祥欢

Owner NANTONG CAPCHEM ELECTRONICS MATERIALS CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com