Isolating transformer

A technology of isolation transformers and transformers, which is applied in the field of transformers, can solve the problem of large common-mode interference of isolation transformers, and achieve the effect of reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

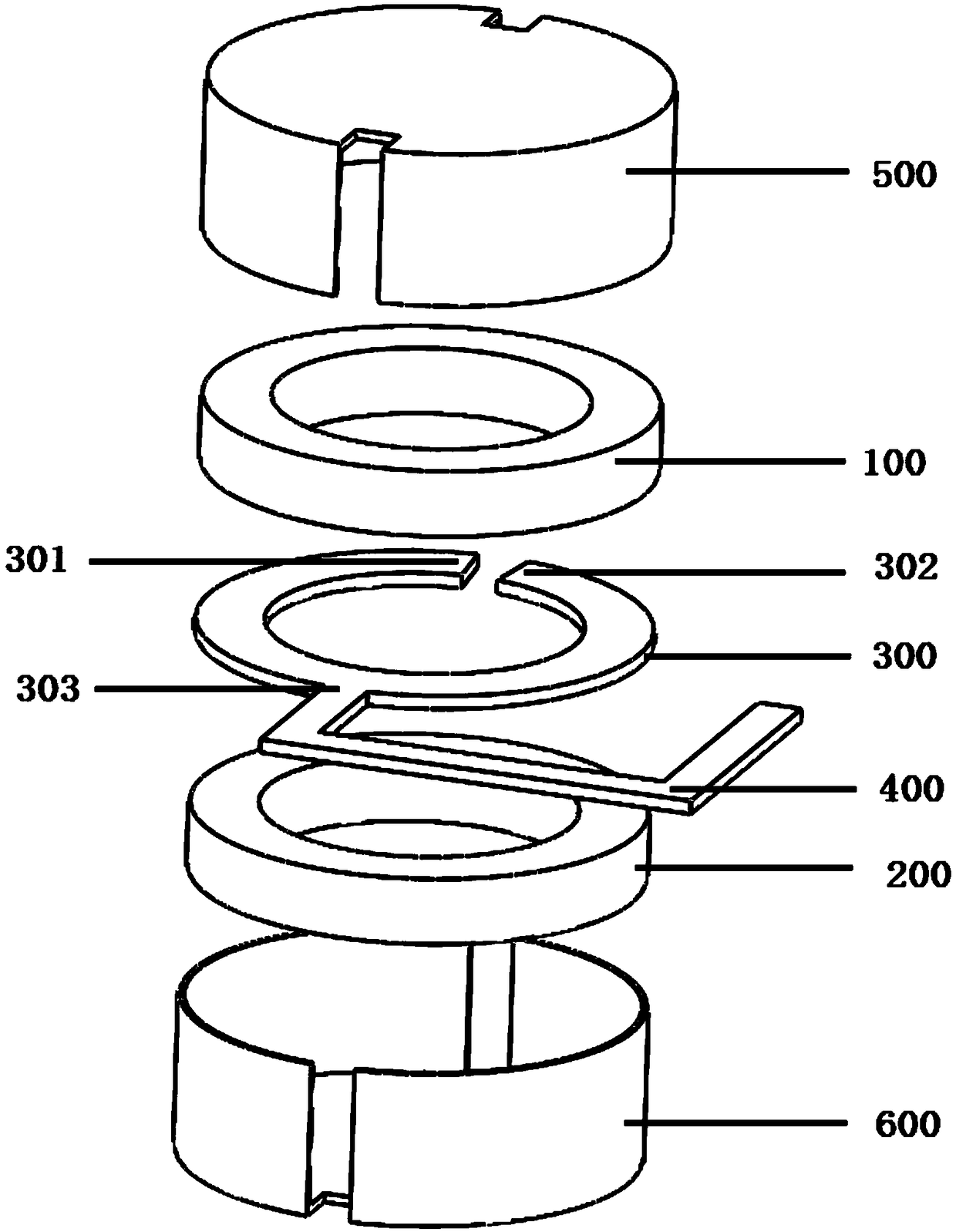

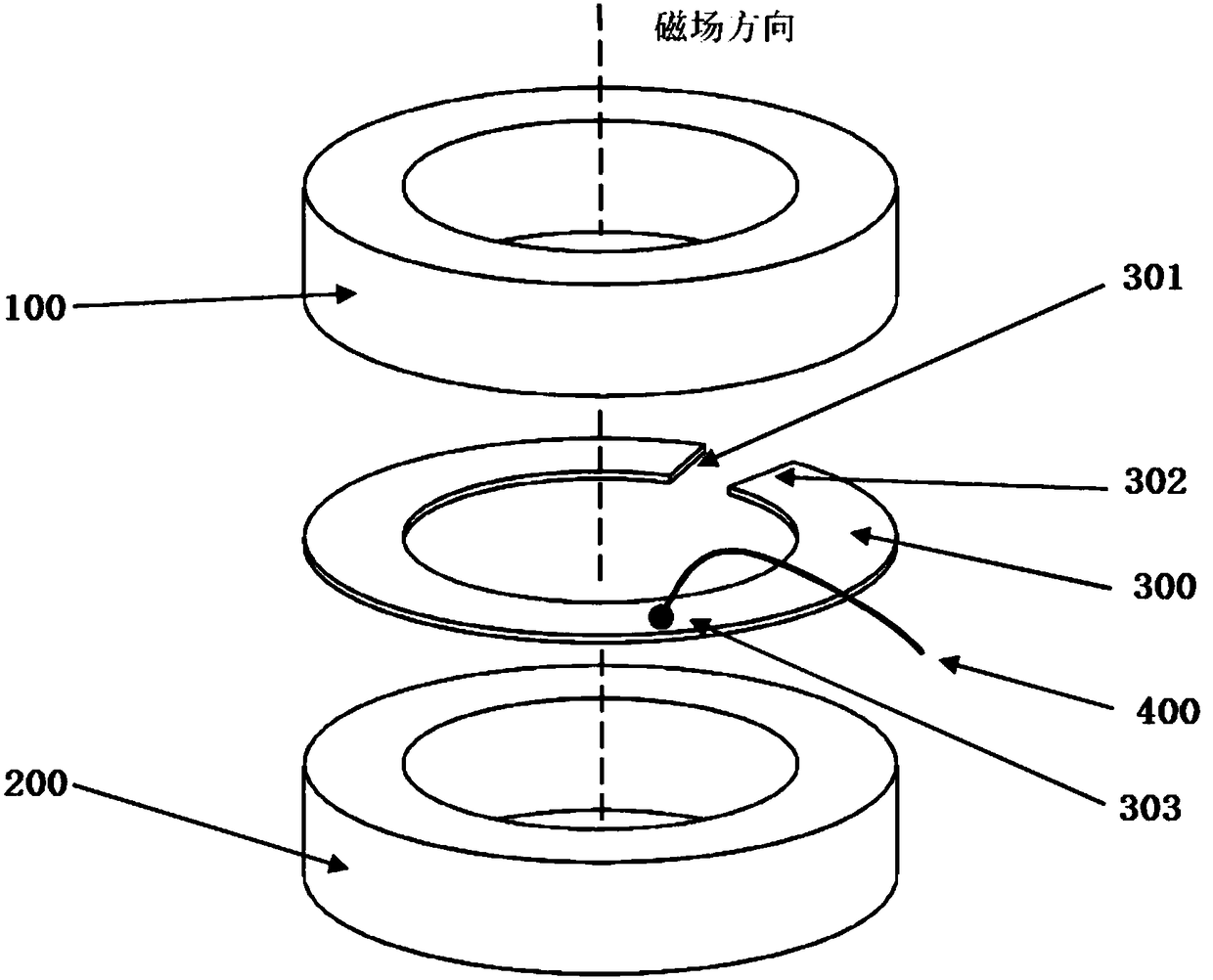

[0032] Such as figure 1 As shown, a preferred embodiment of the present invention provides an isolation transformer with windings arranged up and down, including: magnetic core, magnetic core cover 500, magnetic core base 600, primary winding 100, secondary winding 200, shielding layer 300, the shielding layer potential lead 400, the secondary winding 200 is located at the magnetic core base 600, on which the shielding layer 300, the primary winding 100 and the magnetic core cover 500 are arranged in sequence, the connection between the shielding layer 300 and the shielding layer potential lead 400 The point 303 is located between the two ends 301 and 302 of the shielding layer;

[0033]During specific installation, the turns ratio of the primary winding 100 and the secondary winding 200 is 2:1, a shielding layer 300 is provided between the primary winding 100 and the secondary winding 200, the shielding potential is grounded, and the magnetic core cover 500 and the magnetic c...

Embodiment 2

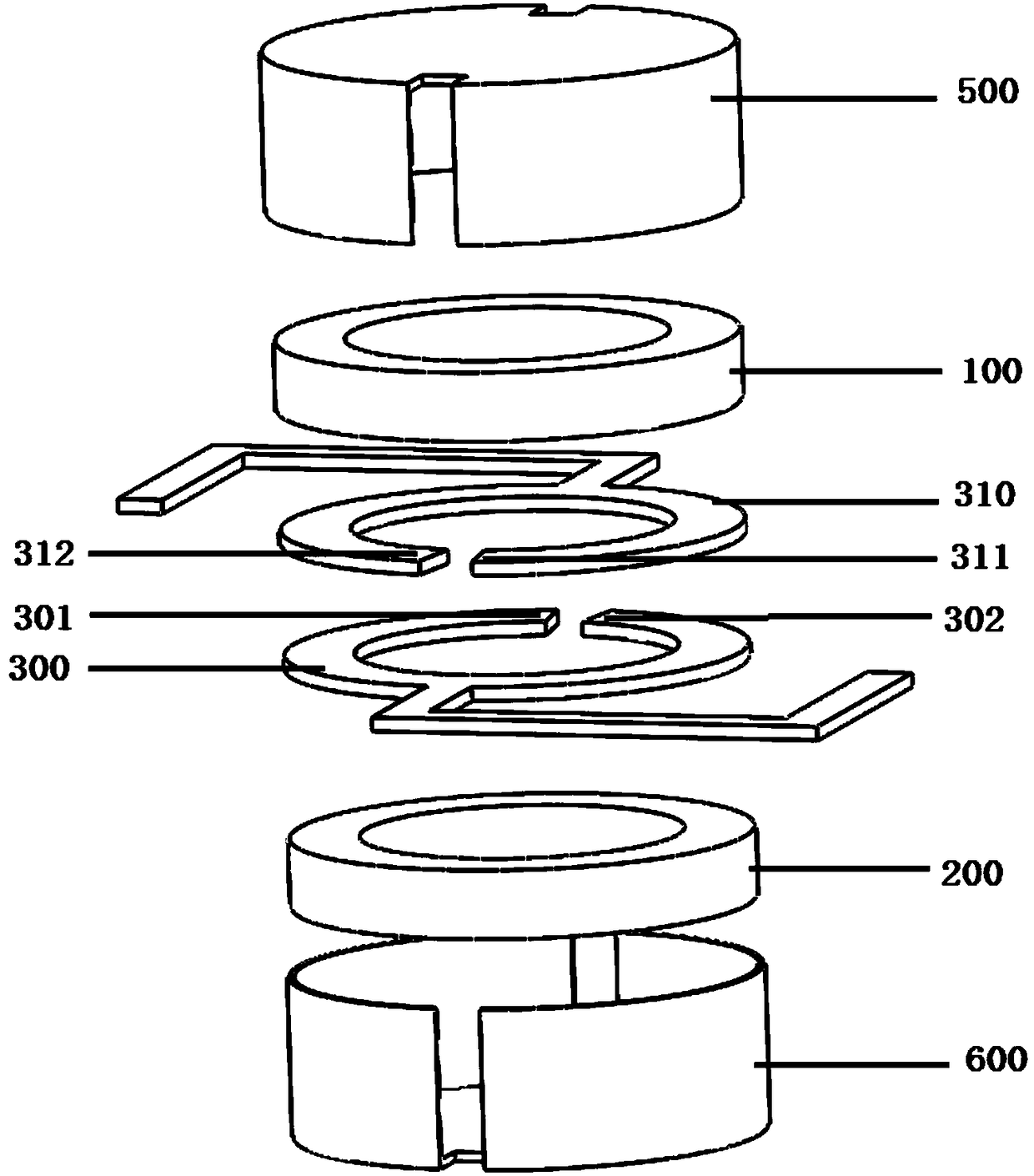

[0040] Such as Figure 5 As shown, another embodiment of the present invention provides a lead position when the winding is arranged inside and outside, including the primary winding 100, the secondary winding 200, the shielding layer 300, and the shielding layer potential lead 400. The secondary winding 200 is located at The outermost side of the transformer is the shielding layer 300 and the primary winding 100 from outside to inside. The connection point 303 between the shielding layer 300 and the shielding layer potential lead 400 is located between the two ends 301 and 302 of the shielding layer. The shielding potential lead 400 Connect the other end to ground.

[0041] Specifically, the working principle of the isolation transformer with windings arranged inside and outside involved in the second embodiment is the same as that of the isolation transformer with windings arranged up and down involved in the first embodiment above. When the shielding layer 300 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com