Parameter-optimized machine learning fault diagnosis system

A fault diagnosis system and machine learning technology, applied in the general control system, control/adjustment system, test/monitoring control system, etc., can solve the problems of low false alarm rate, easy to be affected by human factors, low false alarm rate, etc. , to achieve good forecasting effect, easy forecasting effect, and overcome the effect of low forecasting accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be described in detail below according to the accompanying drawings.

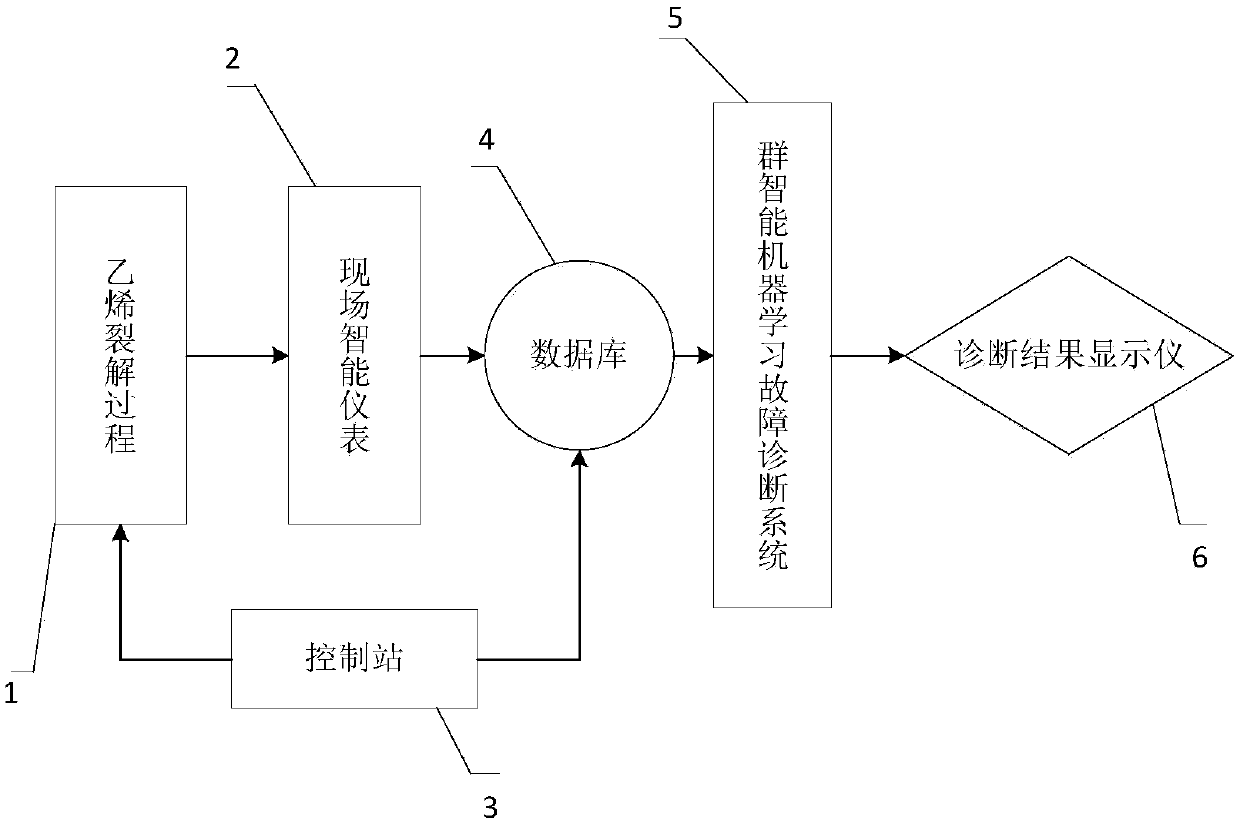

[0049] refer to figure 1 , a machine learning fault diagnosis system with optimal parameters, including ethylene cracking process 1, on-site intelligent instrument for measuring easily measurable variables 2, control station for measuring operating variables 3, database for storing data 4, group intelligent machines Learn fault diagnosis system 5 and diagnosis result display instrument 6. The on-site intelligent instrument 2 and the control station 3 are connected to the ethylene cracking process 1, the on-site intelligent instrument 2 and the control station 3 are connected to the database 4, and the database 4 is connected to the input terminal of the group intelligent machine learning fault diagnosis system 5, The output end of the group intelligent machine learning fault diagnosis system 5 is connected with a diagnosis result display instrument 6 .

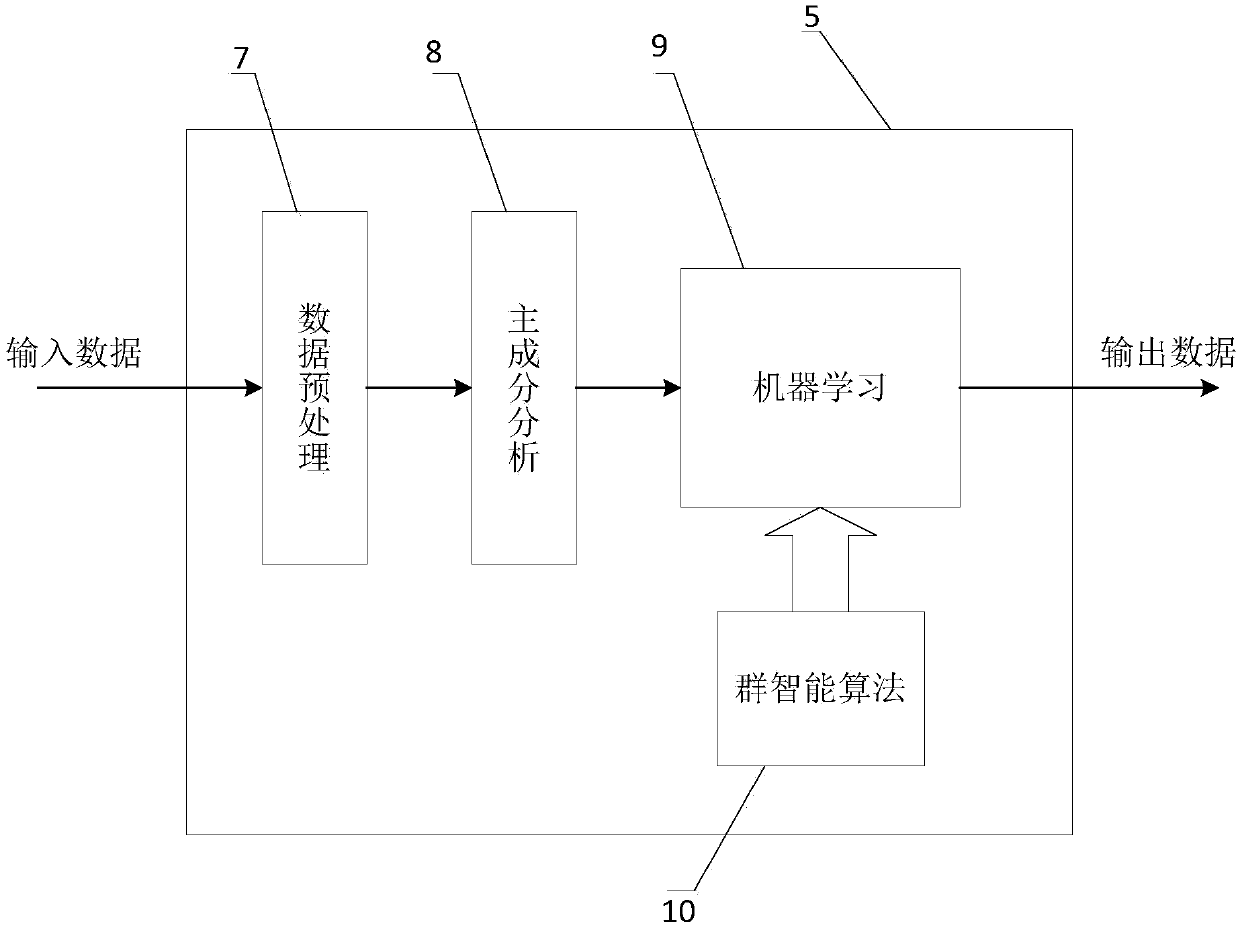

[0050] refer to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com