Terminal crimping quality assessment apparatus, terminal crimping quality assessment method and terminal crimping system

A technology of quality assessment and terminal crimping, applied in the direction of measuring devices, mechanical measuring devices, and mechanical devices, can solve the problems of material waste, low detection efficiency, and high process balance requirements, so as to improve detection efficiency and reduce production costs. , The effect of shortening the detection cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

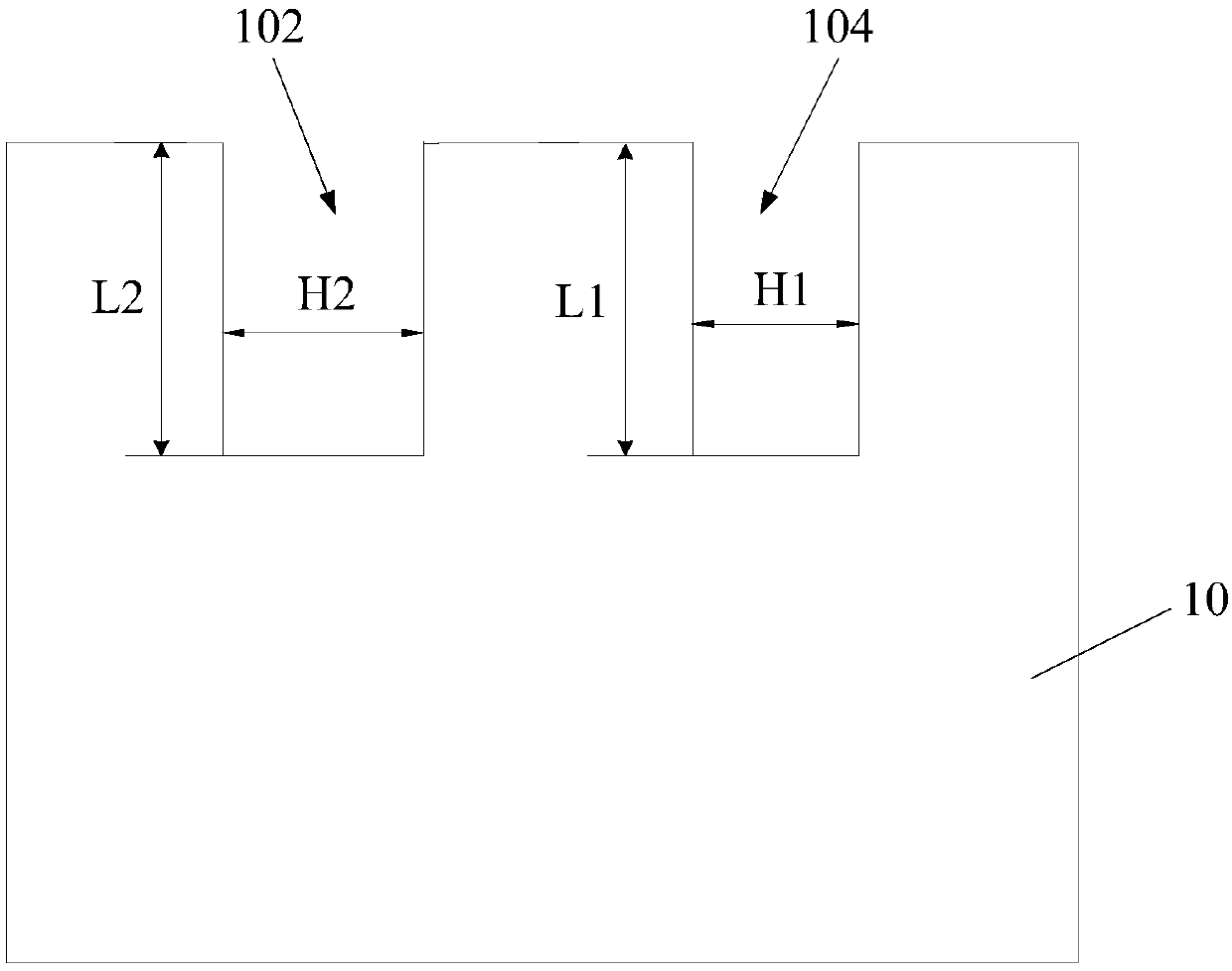

[0091] Embodiment one (as figure 1 shown)

[0092] The measurement slot includes a first sub-slot and a second sub-slot which are independent of each other, the first section 102 forms the first sub-slot, and the second section 104 forms the second sub-slot.

[0093] The measurement slot includes a first sub-slot and a second sub-slot independent of each other, the first section 102 forms the first sub-slot, and the second section 104 forms the second sub-slot, that is, two slots are opened on the test bench 10, so that the first section One section 102 and the second section 104 are set separately, and are respectively used to detect the relationship between the crimping height of the core wire crimping part and the upper limit value and the lower limit value, so that the crimping height of the core wire crimping part and the There is no sequence for judging the upper limit value and the lower limit value, and the detection process is more flexible and free. You can use the fi...

Embodiment 2

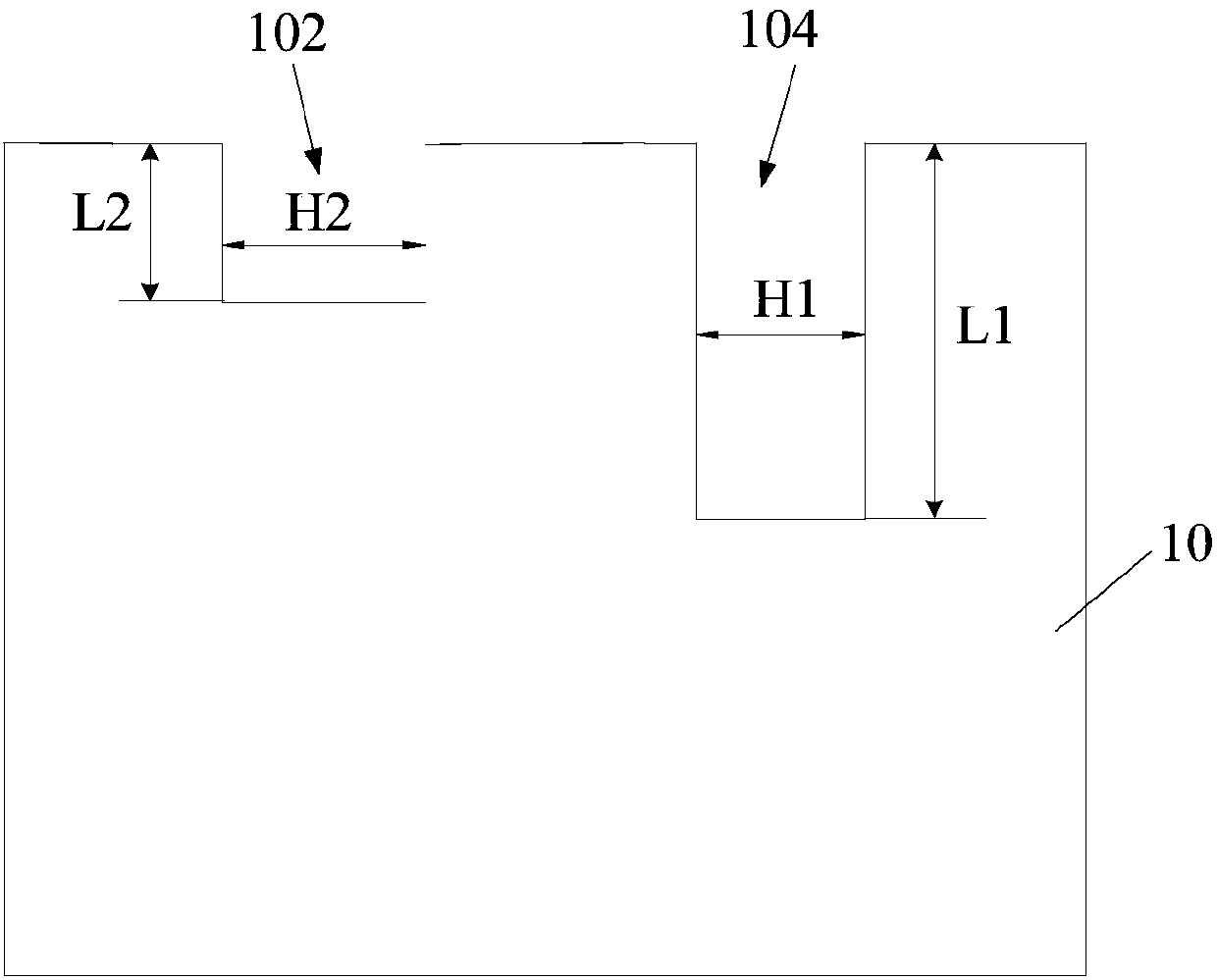

[0097] Embodiment two (as figure 2 shown)

[0098] The difference from Embodiment 1 is that the depth L2 of the first section 102 is smaller than the crimping width, and the depth L1 of the second section 104 is greater than or equal to the crimping width. The evaluation principle is as follows:

[0099] It is relatively simple to first use the second section 104 to evaluate the relationship between the crimping height and the lower limit value.

[0100] If the crimping part of the core wire can all enter the second section 104, then the judgment result is unqualified; if the crimping part of the core wire cannot completely enter the second section 104, it shows that the crimping height does not exceed the lower limit, and then use the first section A period of 102 is used to evaluate the relationship between the crimp height and the upper limit value. If the crimping part of the core wire cannot reach the bottom of the first section 102, the judgment result is unqualified....

Embodiment 3

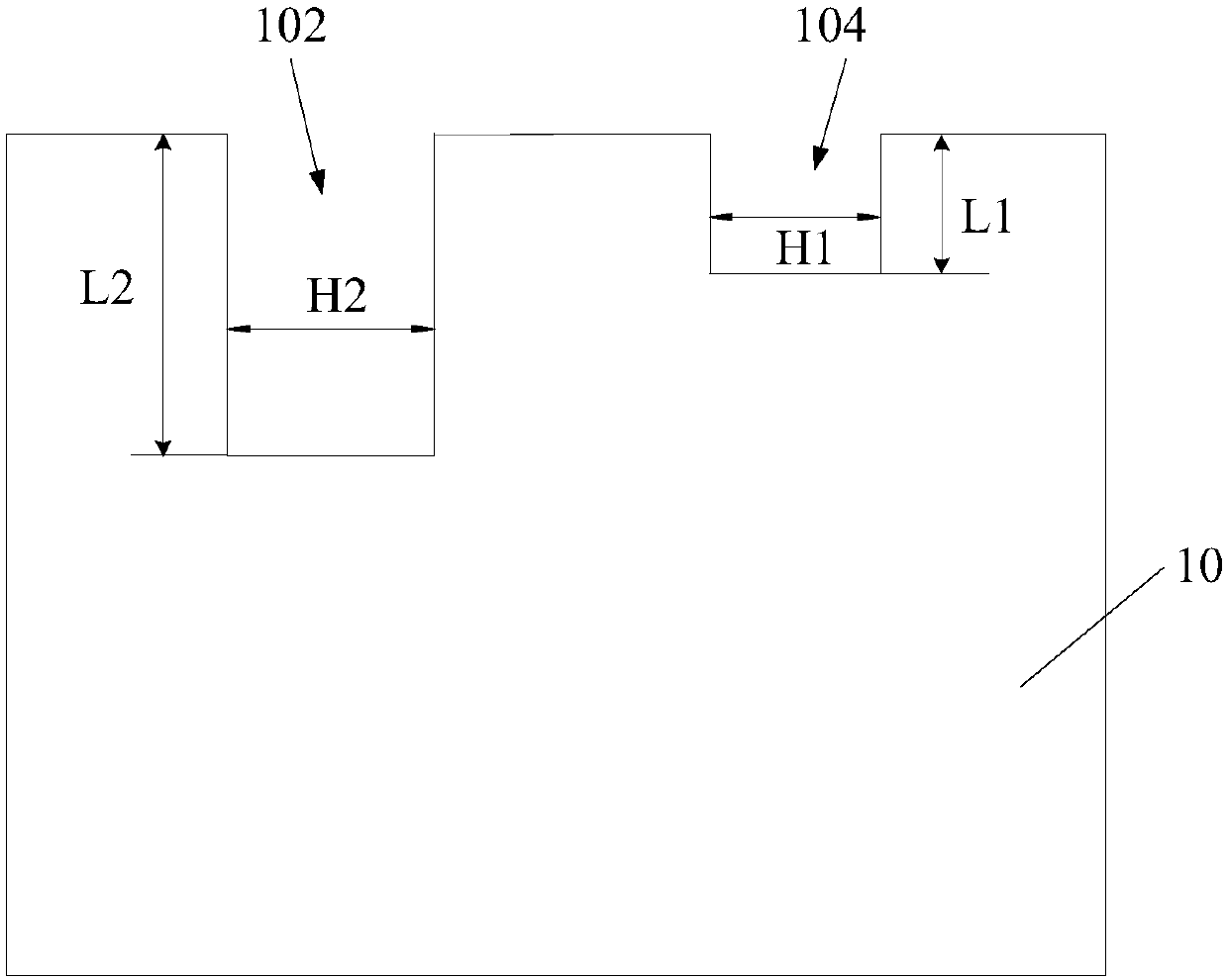

[0101] Embodiment three (as image 3 shown)

[0102] The difference from Embodiment 1 is that the depth L2 of the first section 102 is greater than or equal to the crimping width, and the depth L1 of the second section 104 is smaller than the crimping width. The evaluation principle is as follows:

[0103] It is relatively simple to first use the first section 102 to evaluate the relationship between the crimping height and the upper limit.

[0104] If the crimping part of the core wire cannot completely enter the first section 102, then the judgment result is unqualified; if the crimping part of the core wire can completely enter the first section 102, it shows that the crimping height does not exceed the upper limit, and then use the first section 102. The second stage 104 is to evaluate the relationship between the crimp height and the lower limit. If the crimping part of the core wire cannot reach the bottom of the second section 104, then the judgment result is qualifie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com