Testing device for high-axial-overload test of energetic materials

A test device and high-axis technology, which is used in the test of ammunition, weapon accessories, ammunition, etc., to ensure reliability, save test costs and time, and achieve the effect of anti-overload design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

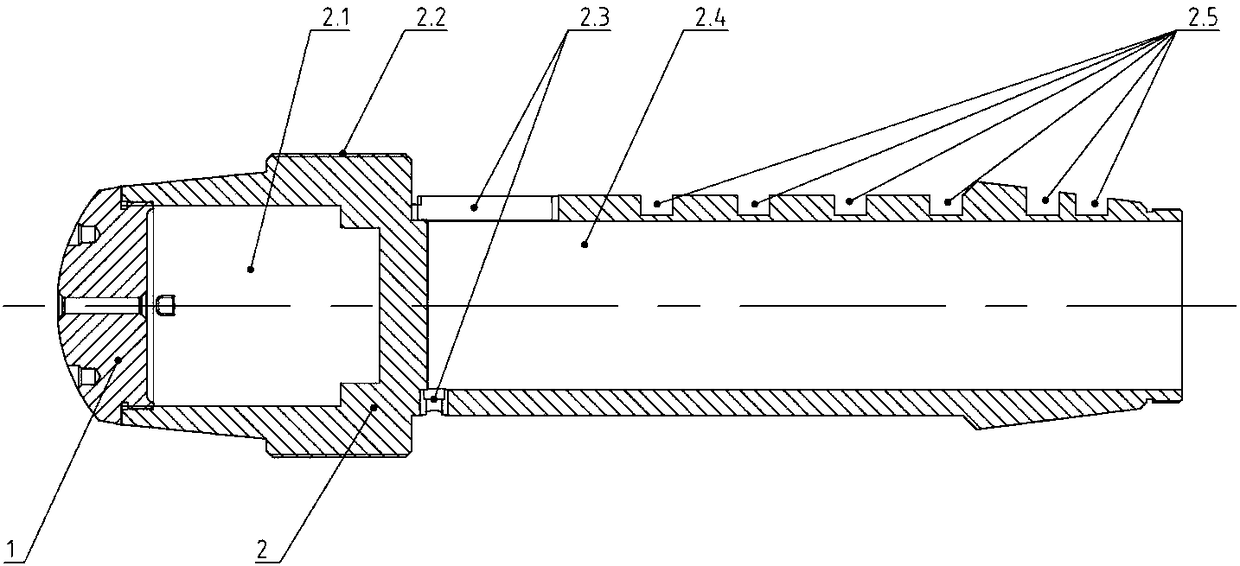

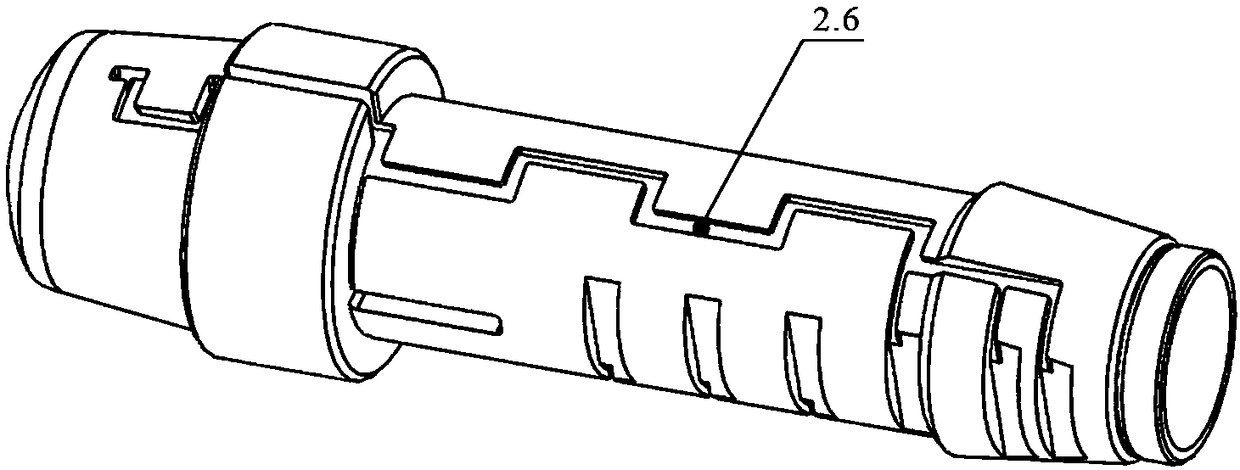

[0028] A test device for high axial overload testing of energetic materials disclosed in this embodiment, such as figure 1 with figure 2 As shown, it mainly includes a front case cover 1 and a medicine case 2 . The drug case 2 mainly includes a data storage system installation space 2.1, a connecting thread 2.2, a displacement sensor installation slot 2.3, a full-size charge installation space 2.4, a strain gauge installation slot 2.5 and a wiring slot 2.6. The front case cover 1 and the cartridge case 2 are connected by threads to seal the data storage system in the installation space 2.1 of the data storage system; the test device is connected with the modified standard cartridge case through the connection thread 2.2 to form a test projectile; Placed in the full-size charge installation space 2.4; the displacement sensor installation groove 2.3 and the strain gauge installation groove 2.5 respectively install the optical displacement sensor and the strain gauge; the cable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com