Flat gate valve with multiplexed output adjustment

A multi-output, slab gate valve technology, applied in the direction of sliding valves, valve devices, mechanical equipment, etc., can solve the problems affecting the sealing performance of the valve, the deformation of the joint between the gate plate and the valve stem, etc., to reduce back pressure, reduce wear, compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings.

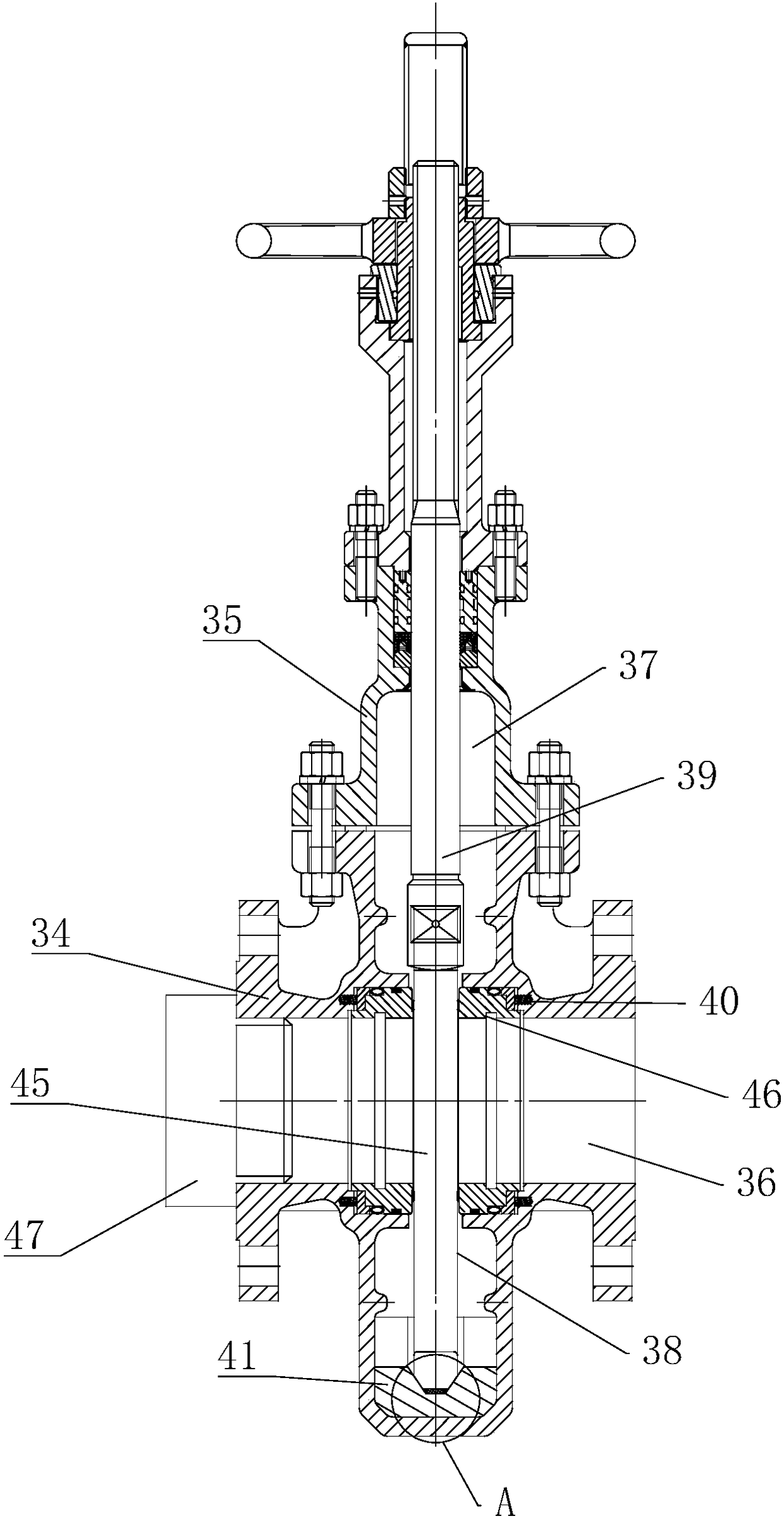

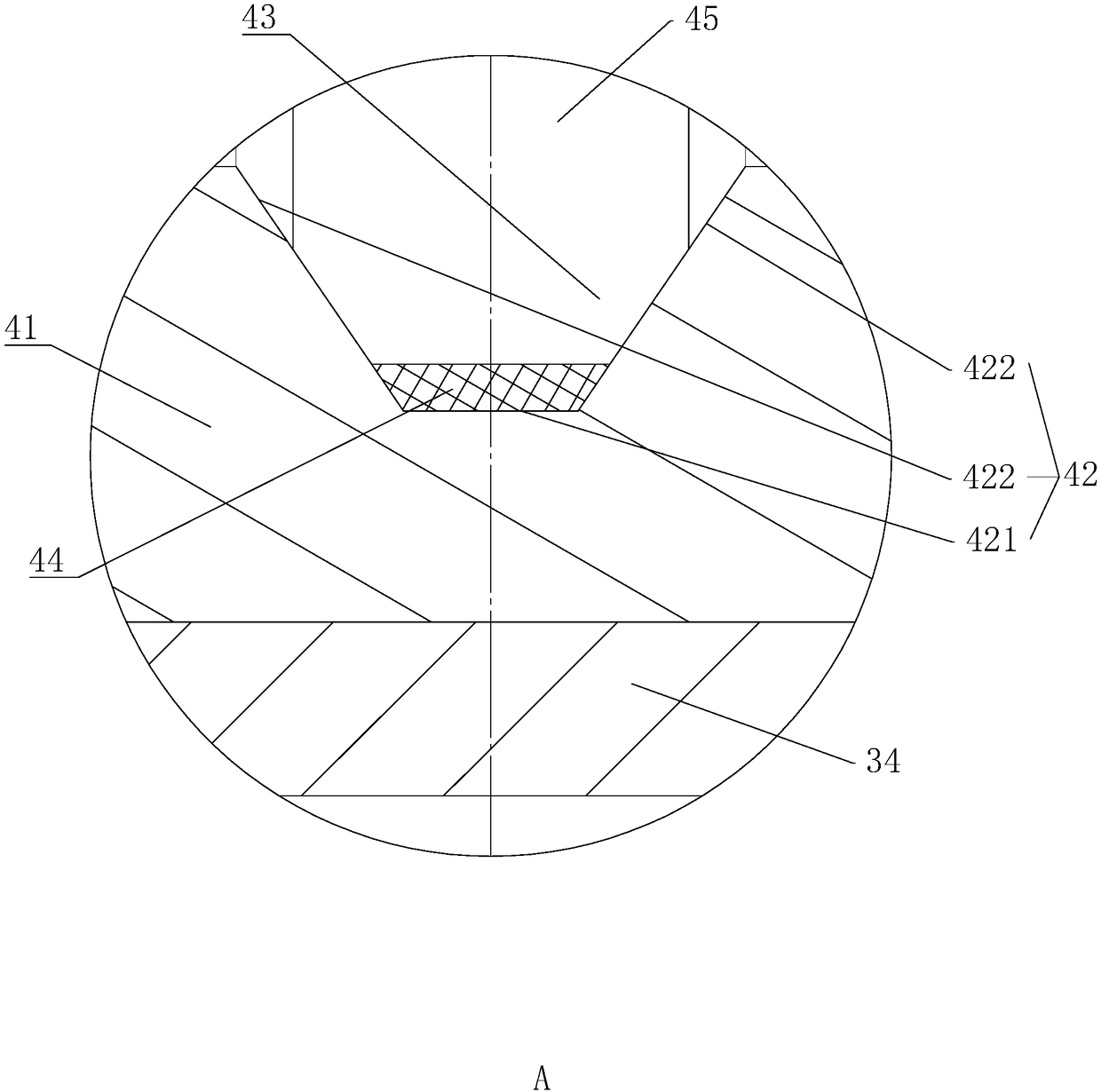

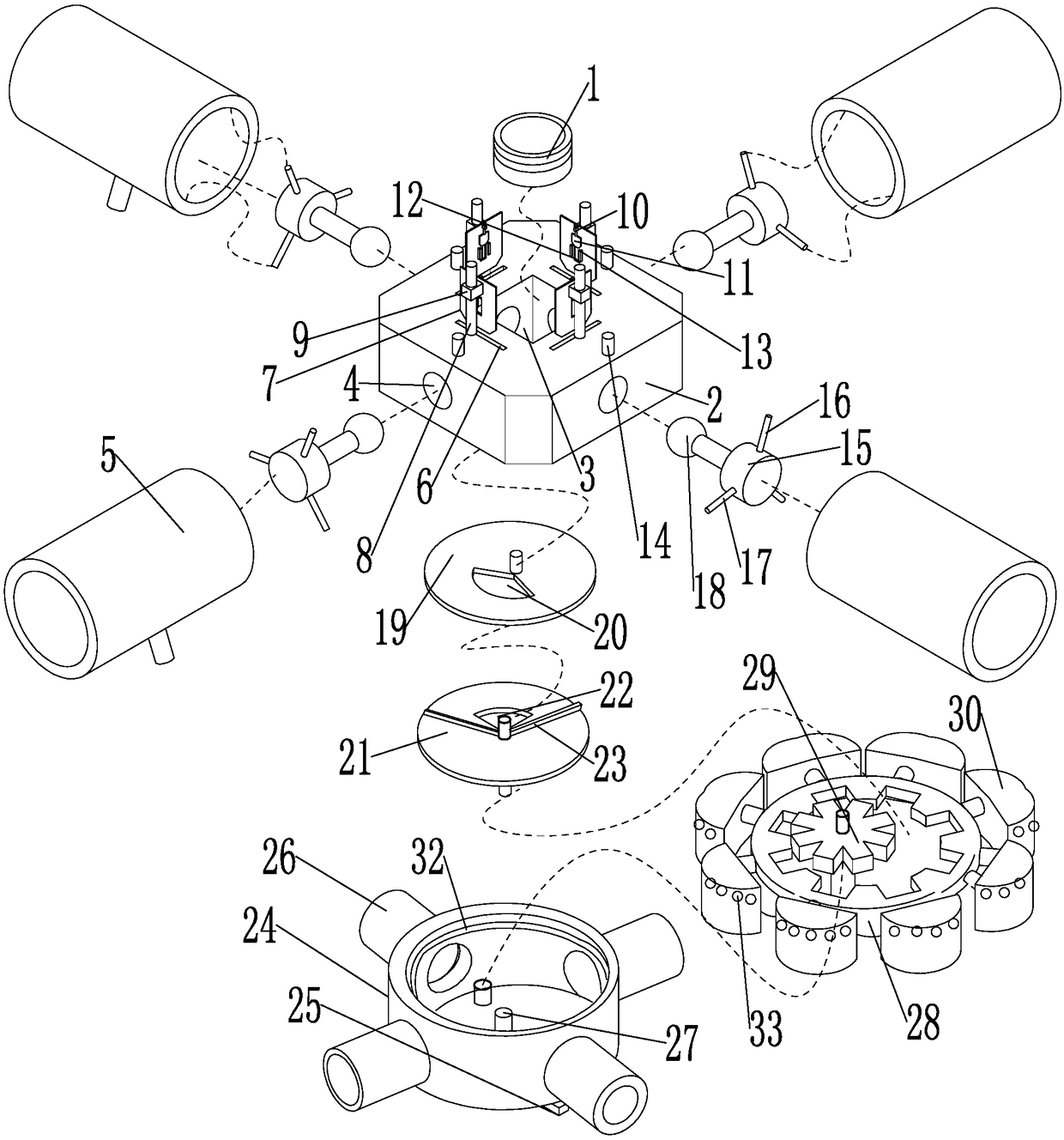

[0030] refer to Figure 1 to Figure 4 , a flat gate valve with multi-channel output adjustment, including a valve body 34 and a valve cover 35 fixedly arranged on the valve body 34, a flow channel 36 is opened in the valve body 34, and a flow channel 36 is opened in the valve body 34 above the flow channel 36 There is an upper cavity 37 communicating with it, and a lower cavity 38 communicating therewith is opened in the valve body 34 below the flow channel 36 , and the lower cavity 38 is located directly below the upper cavity 37 . A valve stem 39 extending into the upper cavity 37 is installed on the bonnet 35, and one end of the valve stem 39 located inside the upper cavity 37 is fixed with a gate 45, and a valve seat 46 that cooperates with the gate 45 to realize sealing is installed in the flow channel 36, A spring 40 is provided between the valve seat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com