Light-weight X-ring oil seal chain of large-displacement locomotive

A lightweight, large-displacement technology, applied in the chain field, can solve problems such as the inability to meet the performance requirements of locomotives, and achieve the effect of solving the shrinkage of the inner diameter of the sleeve, improving the oil sealing performance, and improving the overall life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

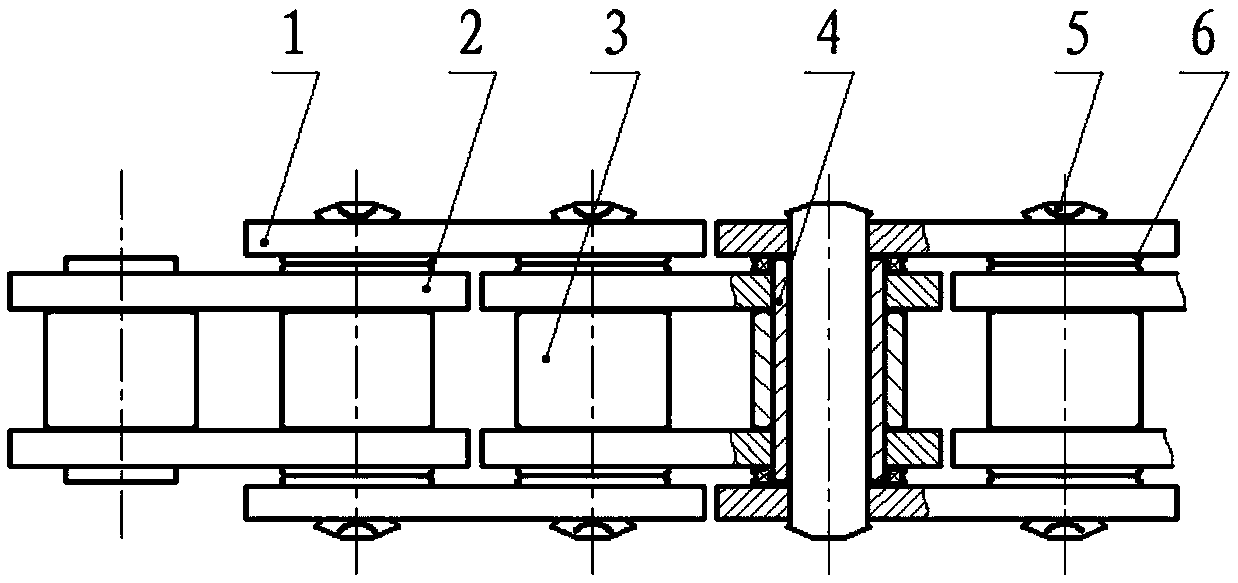

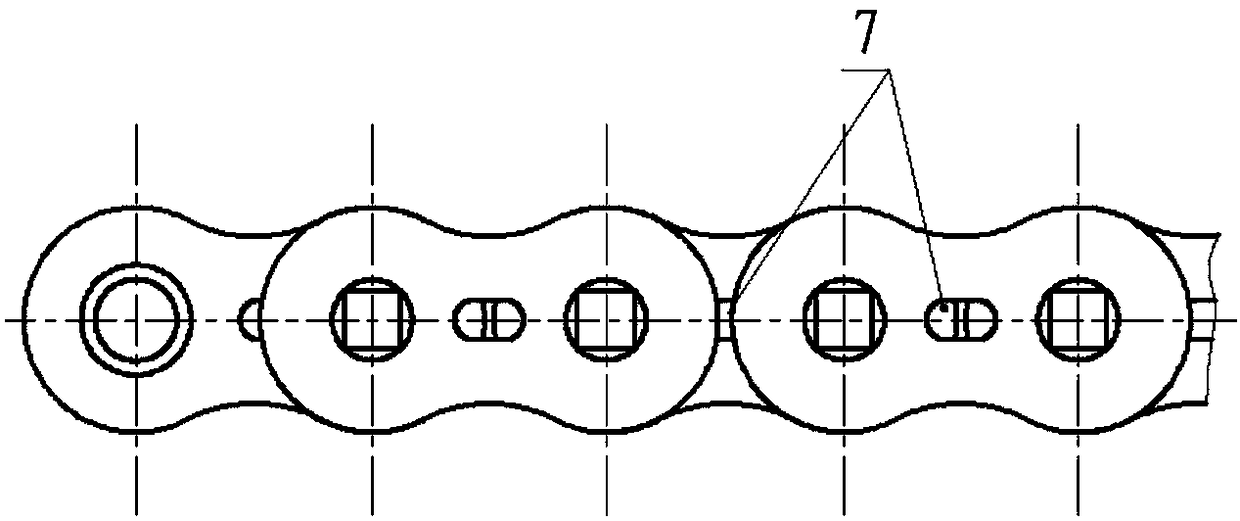

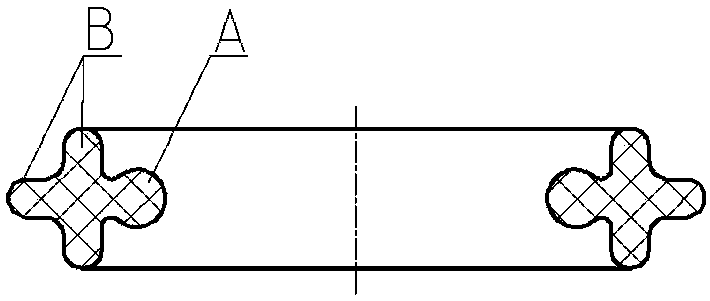

[0018] A lightweight X-ring oil seal chain for a large-displacement locomotive, which is composed of an outer single joint, an inner single joint and a sealing ring 6, the sealing ring 6 is located between the contact surfaces of the inner and outer single joints; the inner single joint is composed of a sleeve 4, The inner chain plate 1 and the roller 3 are assembled and matched; the outer single joint is composed of the pin shaft 5 sleeved in the sleeve 4 and the outer chain plate 2 through interference fit; the sealing ring 6 is lip-shaped: the outer chain plate 2 1. The inner chain plate 1 adopts the same sheet shape and narrow waist structure, and the inner and outer chain plates are all provided with lightening holes 7 to reduce the chain weight. After the two ends of the pin shaft 5 pass through the sleeve 4 and the outer chain plate 2, they are locked and fixed by square riveting heads. The sealing ring 6 is made of carboxylated nitrile butadiene rubber or fluorine rubb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com