A fan device with self-cleaning function

A function, fan technology, applied in the field of fan devices with self-cleaning function, can solve the problems of increased motor energy consumption, low extraction and exhaust flow efficiency, unsatisfactory and other problems, and achieves simple and easy to achieve structure and good cleaning effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

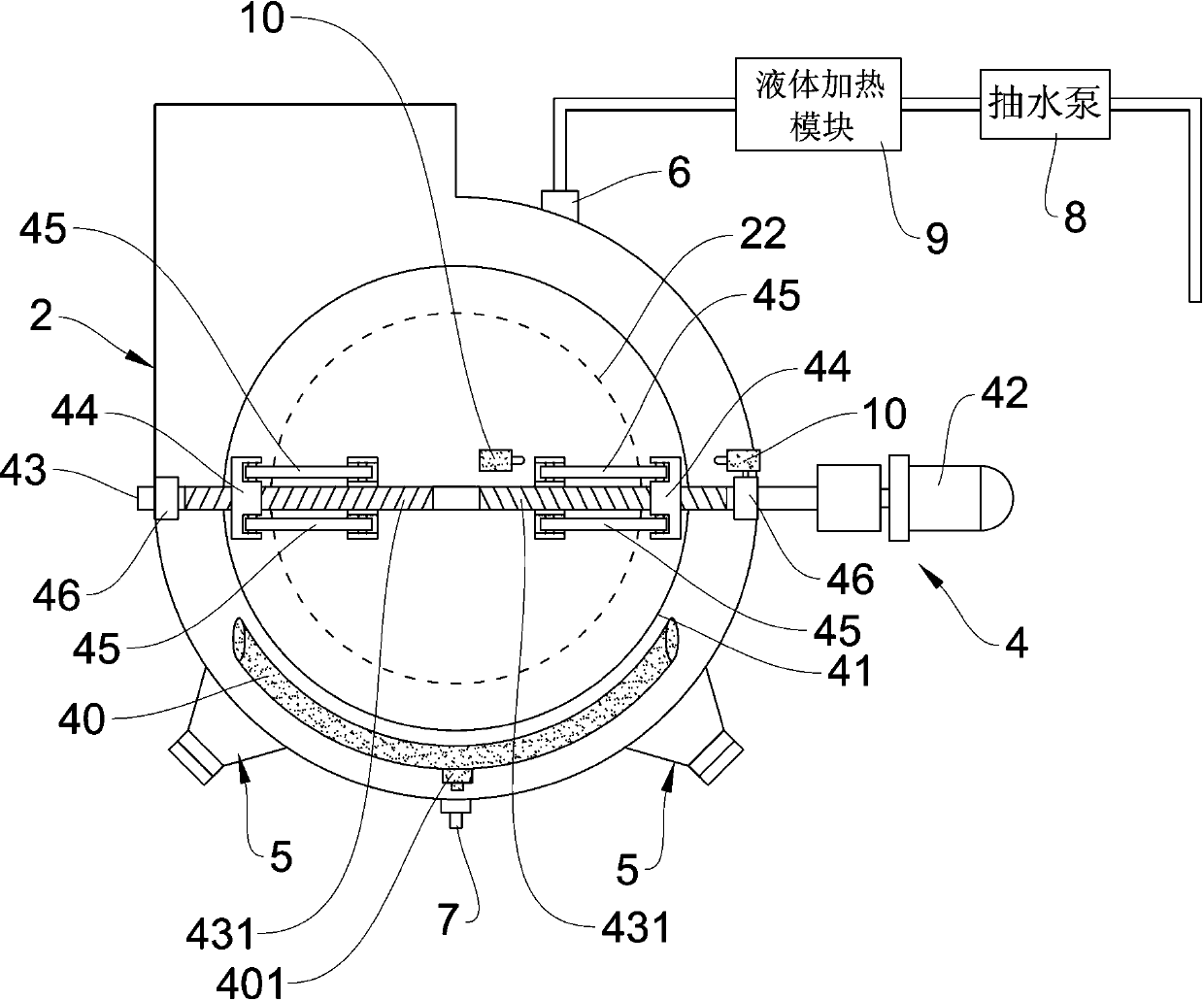

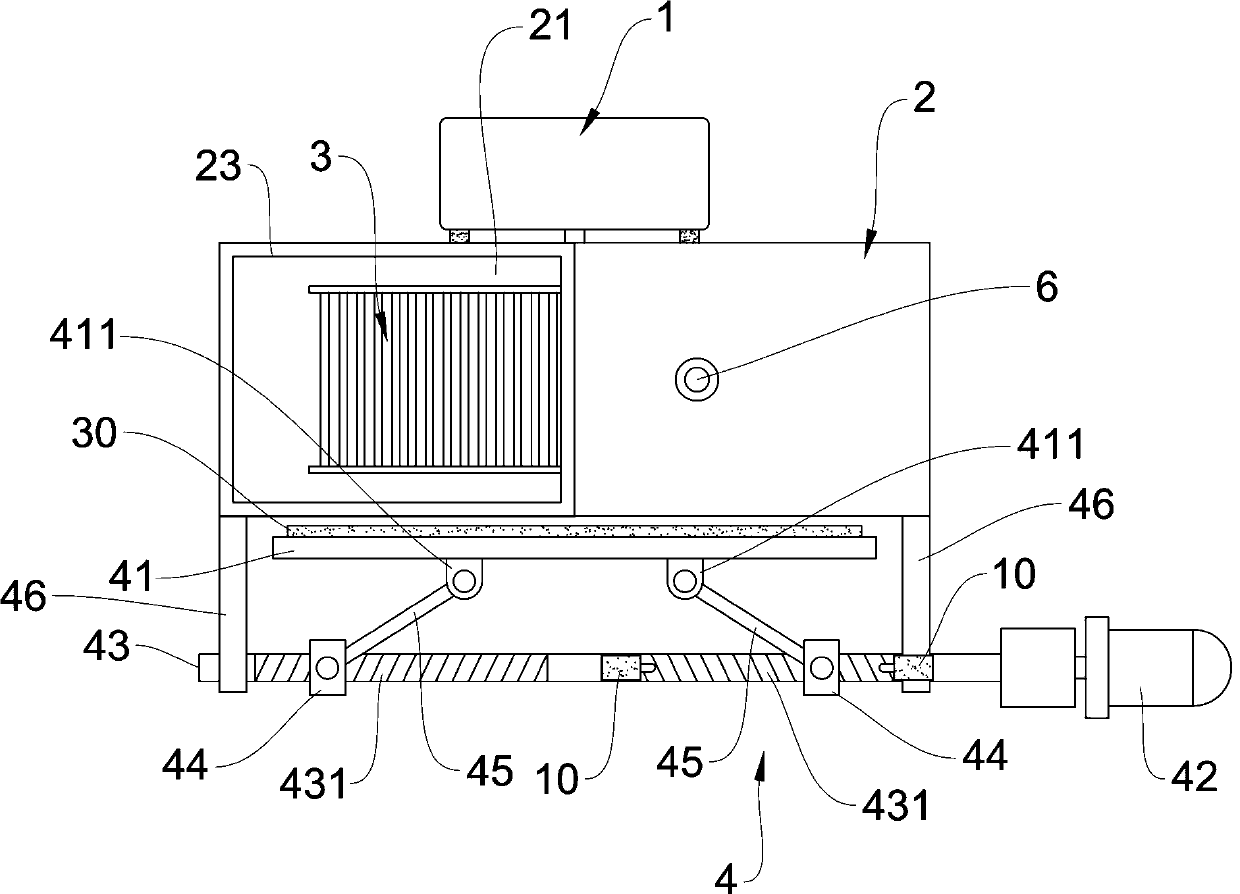

[0015] Such as figure 1 , figure 2 As shown, a fan device with a self-cleaning function according to the present invention includes an impeller motor 1, a fan casing 2, and an impeller 3. The fan casing 2 is provided with a closed chamber 21 for the impeller 3 to accommodate. , an air inlet 22 and an air outlet 23 are respectively arranged on the fan housing 2; the impeller motor 1 is arranged outside the fan housing 2, and the motor shaft of the impeller motor 1 extends into the airtight chamber 21; The impeller 3 is arranged in the airtight chamber 21 of the fan casing 2 and connected with the motor shaft of the impeller motor 1 . In order to realize the fan self-cleaning function proposed by the present invention, the present invention also includes a capping mechanism 4, an ultrasonic transducer 5,

[0016] another example figure 1 with figure 2 As shown, the capping mechanism 4 includes a cover plate 41, a capping motor 42, a screw rod 43, a nut piece 44, and a push...

Embodiment 2

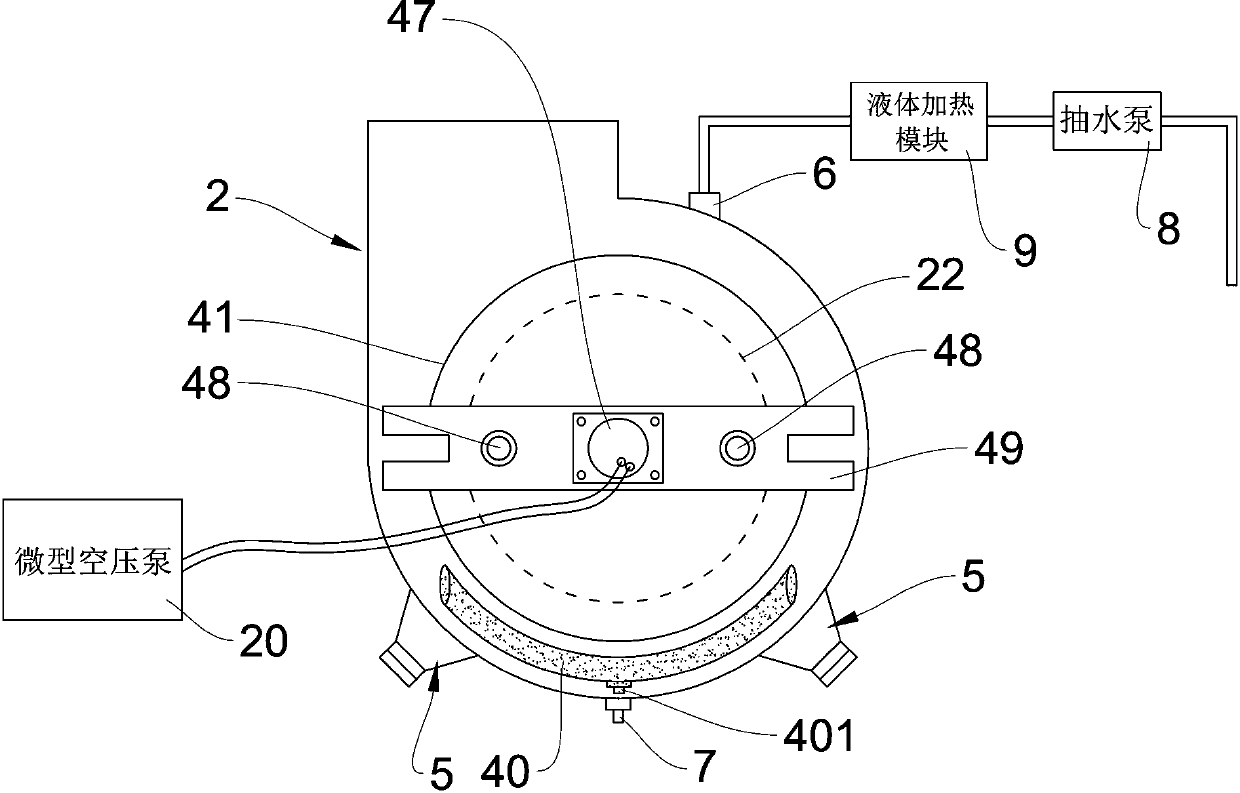

[0024] The difference between the second embodiment and the first embodiment lies in the structure of the capping mechanism 4. The capping mechanism 4 of the first embodiment uses a motor to push the opening and closing of the cover plate 41, while the present embodiment Two then adopt air cylinder to promote the opening and covering of cover plate 41. Except for the structure of pushing the cover plate 41 is different, the purpose and principle process to be implemented in the second embodiment are basically the same as those in the first embodiment. Therefore, in the second embodiment, the same parts as those in the first embodiment will not be described repeatedly. The concrete scheme of present embodiment two is like this: as image 3 with Figure 4 As shown, a fan device with a self-cleaning function includes an impeller motor 1, a fan housing 2, and an impeller 3. The fan housing 2 is provided with a closed chamber 21 for the impeller 3 to accommodate. 2 is also provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com